Air-gap polarizers tolerate 10X more power than cemented designs

A scientist at Lumus Optical (Rehovot, Israel) has developed a new coating-design technique (patent pending) for a polarizing cubic beamsplitter. Using a Fabry-Perot configuration with two identical coated mirrors separated by an air space, the polarizer was modeled to ensure that the angle of incidence in the coating is below the total internal reflection (TIR) angle to achieve high extinction ratio (>100:1) and high laser damage threshold (LDT) for a 1065 nm YAG laser.

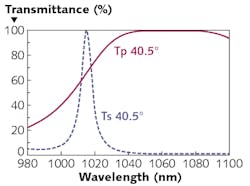

Based upon modeling parameters, two fused-silica prisms with identical coatings were designed to be optimized at an incident angle of 40.5°. With a high reflection for s-polarization and a low reflection for p-polarization for each separate mirror, and modeling the air space as a thin layer, the overall design resulted in a wide-spectrum polarizer. To achieve high LDT, hafnium oxide (HfO2) and silicon dioxide (SiO2) were chosen as the coating materials. Experimenting with 6 and 15 alternating high- and low-index layers transmitted >99.5% of the p-polarization and <0.5% of the s-polarization. Optimization with OptiLayer software (www.optilayer.com) resulted in single- and double-wavelength designs (for 1065 and 1540 nm) with high-extinction performance that survived laser power levels of >500 MW/cm2 compared to cemented polarizers that could only withstand power levels of <50 MW/cm2. Reference: M. Gilo, Optical Interference Coatings (OIC) conference paper 2482171, Tucson, AZ (Jun. 2016).About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.