A nanostructured silicon dioxide (SiO2) thin film developed by scientists at Rensselaer Polytechnic Institute (RPI; Troy, NY) may help expand the capabilities of multilayer thin-film anti- and high-reflection optical coatings. The film’s outstanding property: it’s mostly air.

Multilayer thin-film optical coatings require material layers of high and low refractive index (typically in alternating order) to work well. The greater the difference in index between the layers, the easier it is to design a high-performance coating, and the further the limits of the coating’s performance can be pushed. On the forefront of optical-coating technology is the drive to increase the refractive-index difference. One approach, taken by the Massachusetts Institute of Technology and Omniguide (both of Cambridge, MA), is to boost the high-index end by using exotic materials such as chalcogenide glass (see www.laserfocusworld.com/articles/19537).

The alternate approach is to bring down the low-index end. Until the advent of nanostructured materials, the only option was to use an air gap for some of the layers-mechanically, a very impractical solution indeed. A more recent option is solgel-produced nanoporous aerogels, but they are difficult to produce to precise thicknesses.

Leaning nanorods

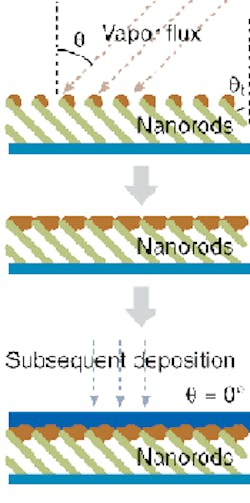

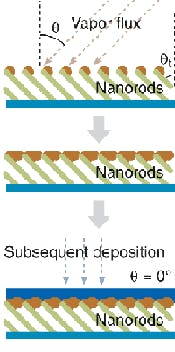

The RPI researchers use oblique-angle electron-beam deposition to grow nanorods that lean away from the normal by about 45°; the resulting refractive index is approximately 1.08 in the red and near-IR range, and results from a porosity of 80.5% (see figure). Depositing a small amount of additional material from the opposite angular direction seals the layer, allowing conventional thin films to be subsequently deposited. The electron-beam-deposition process allows the thickness of the nanorod films to be tightly controlled.

“We have not observed a strong anisotropy in the film,” notes Fred Schubert, one of the researchers. “In fact, we have not observed any anisotropy at all. We think that this is due to the very low refractive index of the film. In the limit of a very porous material, the index of the solid material becomes increasingly less important and the refractive index of the gaseous pores becomes increasingly more important. The gaseous material obviously does not exhibit anisotropy.”

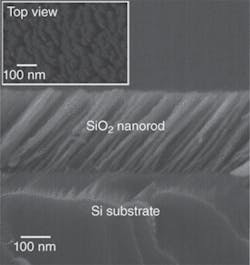

The RPI researchers fabricated a simple single-pair dielectric reflector composed of a 41-nm-thick layer of silicon, a 150.9-nm-thick SiO2 nanorod layer, and a silicon substrate; they also fabricated a conventional single-pair reflector of silicon and dense SiO2. The root-mean-square surface flatness for the two films was 5.2 and 2.8 nm, respectively, while the peak spectral reflectivity was 78.9% and 72%, respectively. Schubert has found the adhesion of silicon to the nanorod layer, as well as the mechanical stability of the nanorod layer, to be very good.

“We are very excited about these films, as they constitute a new class of optical materials with a potentially wide range of applications,” says Schubert. “We anticipate that many optical thin-film structures will benefit from this material, including reflectors, filters, optical resonators, and resonant microcavities. Generally, using low-refractive-index films allows one to use fewer layers or layer pairs, reduce weight, reduce potential absorption effects, and attain omnidirectionality of reflection.”

REFERENCE

1. J.-Q. Xi et al., Optics Lett. 31(5) (March 1, 2006).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.