ORGANIC LASERS: Colloidal mirror tunes laser when compressed

Tunable visible lasers tend to be large and expensive, at least when compared to their compact fixed-wavelength counterparts such as HeNe, diode, and low-power frequency-doubled Nd:YAG lasers. But researchers at the Center for Optical Materials Science and Engineering Technologies at Clemson University (Clemson, SC) have created an orange-red-emitting organic laser with an easily tuned colloidal mirror that gives the emitter a 32-nm tuning range.1 Although the test device is pumped by a bulky nitrogen-laser-pumped dye laser, versions could be made that are pumped by small solid-state lasers.

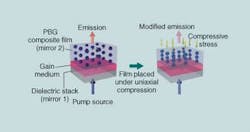

A layer of Rhodamine-B dye in poly(methyl methacrylate) (PMMA) is deposited on an ordinary broadband dielectric-stack reflector that serves as one of the cavity mirrors. The dye/PMMA gain layer is made only 1 μm thick to reduce the number of resonator longitudinal modes.

The other cavity mirror is far more exotic. Polystyrene spheres of 150-nm diameter are encapsulated within a composite film so that they form a regular photonic-bandgap (PBG) array (see Fig. 1). To fabricate the film, the spheres are first mixed into a hydrogel layer. The spheres do not touch, however; electrostatic forces hold them away from each other and in a regular grid. The water in the hydrogel is then removed and replaced with other substances that are photopolymerized, resulting in a rugged film that reflects highly within a certain spectral band. A test PBG film was 125 µm thick and reflected at 644 nm (uncompressed) with a full width at half maximum of 20 to 30 nm.

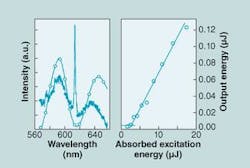

Physically compressing the film brings the spheres closer together in the compressive direction, changing the mirror’s peak reflection wavelength. The pressure applied to change the thickness enough to tune by 32 nm is about 50 kPa. “To apply the pressure, we mount an optical flat window perpendicularly on a high-resolution translation stage,” says Justin Lawrence, one of the researchers. “The stage is moved by a piezoelectric actuator, allowing the optical flat to compress the colloidal mirror.”When the gain layer is pumped at below threshold, its photoluminescent spectrum exhibits a dip centered at 620 nm, which is approximately where the PBG mirror reflects the most. When pumped above threshold, a laser line appears in the dip (see Fig. 2). The 32-nm tuning range is limited by the intrinsic absorption of the dye/PMMA layer; the PBG mirror itself is capable of a much wider tuning range.

“The main advantage of this type of structure is that it is independent of the gain medium,” notes Lawrence. “During fabrication, the colloidal mirror can be simply laminated or pressed onto the gain material. The colloidal mirror can be tuned over 200 nm, so it could work with a wide range of laser dyes. It could also work with other types of gain materials-perhaps a polymer film doped with nanoparticles, for example.” The mirror can be modulated in the low kilohertz range, says Lawrence, making it possible to switch the laser, either turning it on and off or flipping between different wavelengths.

REFERENCE

1. 1. J.R. Lawrence et al., Advanced Materials 18, 300 (2006).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.