Electrostatic Rydberg-atom mirror reflects hydrogen

Adding to the repertoire of atomic optics, in which atoms are manipulated as if they were photons (see “Coherent atoms are on the move,” p. 97) researchers at ETH Zürich (Zurich, Switzerland) have created a normal-incidence atom mirror. The device works with Rydberg atoms (in this case, hydrogen), which have at least one orbital electron excited to a very high quantum state, making the atoms easily influenced by external electric fields. The electrostatic mirror consists of four electrodes that create an electric field of about 2000 V/cm.

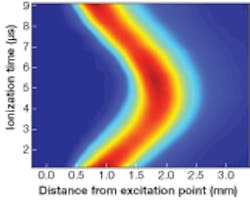

Hydrogen atoms in a supersonic flow were created by photolysis of ammonia with a 193 nm excimer laser. Counterpropagating UV and vacuum-UV laser beams then photoexcited the atoms to the n = 27 Stark state. Initially moving at 720 m/s, the Rydberg atoms were stopped by the mirror 1.9 mm away from the spot where they were photoexcited, and were reflected back to their original position in about 9.8 µs. The mirror also focused the atom cloud in one dimension. The atom cloud was imaged by suddenly ionizing the atoms with an electric-field pulse, making the cloud visible on a phosphor screen. Contact Edward Vliegen at [email protected].