Nano-optics boost projection-display performance

JIAN WANG, NADA O’BRIEN, and MARIA LIGHT

The bar keeps getting raised for projection television and front-projector performance as the competition heats up against plasma and flat-panel televisions. Both rear- and front-projection displays can be designed with either digital-light-processing (DLP) or liquid-crystal-on-silicon (LCOS) technology. The latter offers the advantage of inherent high resolution and high fill factor (minimal dark space between pixels). Because the pixilation in the image is minimized, an observer experiences a smooth, rich viewing experience. While LCOS offers high performance in comparison to other technologies, subwavelength optical elements can further enhance performance.

Subwavelength optical elements

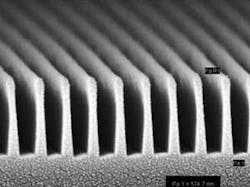

When light interacts with subwavelength grating structures—in which the dimensions are at least an order of magnitude smaller than the wavelength of the light—classical models of optics essentially break down and new properties come into play. These effects can be used to design periodic structures composed of various material and dimensions that can result in a number of optical functions, and they enable the fabrication of very compact waveplates, polarizers, filters, and lenses (see Fig. 1).

Fabrication of subwavelength optical structures is actually a reengineering of the material’s optical property. For example, one such optical property, the refractive index, can be engineered by selecting the index of the base material, index of the fill material, and the duty cycle of the two. By engineering these three parameters, subwavelength optical elements with various index profiles and therefore different optical functions can be generated. The shape of the periodic structure can also be used to tailor optical functionality.

LCOS displays

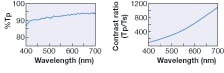

An LCOS imaging panel contains an array of liquid-crystal modulators on a mirror. The liquid-crystal (LC) cells twist or align in response to control voltages and so change the birefringence of the individual cells. In this manner, an image is created by selectively turning the pixels (LC cells) on or off. The key to high contrast is the purity of the polarization of the light reaching and passing through the panel (see Fig. 2).Conceptually, a wire-grid polarizer consists of fine wire grids spaced at a period shorter than the wavelengths used. The oscillating electric fields of the incident light induce electric dipoles at the surface, and the response of the metal to this field determines its optical properties. For light polarized parallel to the wire (TE polarization case), it behaves as a conductor and reflects, whereas for light polarized perpendicular to the wire (TM polarization case), it behaves as a dielectric and transmits.3

Wire-grid technology can also be used for a polarizing beamsplitter in the LCOS light engine, as an alternative to the classic MacNeille-type glass polarizer. A MacNeille cube polarizer consists of two glass prisms with a thin-film stack at the 45° interface. Such devices suffer from a limited acceptance angle and exhibit thermal and stress birefringence. Transmission of p-polarized light through a MacNeille polarizer is high at the nominal angle of incidence but drastically reduced as the angle changes slightly. Contrast is even more sensitive to angle of incidence. Conversely, a wire-grid polarizing beamsplitter has a wide acceptance angle, broad operating spectrum, and does not suffer the effects of impaired performance over temperature.

The newest addition to the subwavelength family of components for LCOS display engines is a trim retarder. This low-retardance waveplate compensates for the slight residual birefringence exhibited by an LCOS panel. To obtain the highest contrast possible, both in-plane (A-plate) and out-of-plane (C-plate) compensation must be accomplished by the trim retarder.

The conventional approach is to use birefringent plates for A-plate compensation accompanied by a dielectric stack for negative C-plate compensation. Traditional birefringent waveplates are typically crystal quartz. True zero-order waveplates are generally preferred for demanding applications because they are the least sensitive to variations in wavelength, angle of incidence, and temperature. However, true zero-order waveplates with low retardance (about 5°) are difficult to manufacture and expensive. Stretched polymers can be used for phase management, but the large temperature variation and limited environmental durability are challenges.

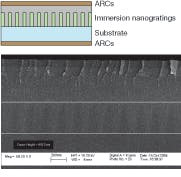

A trim retarder can be designed and fabricated using subwavelength optical structures. These structures generate only zero-order diffraction modes: all higher-order modes fall away. A subwavelength trim retarder consists of a grating structure made of homogeneous dielectric materials, which breaks the in-plane symmetry of the material and leads to an artificial birefringence property, namely form birefringence.4 The form birefringence concept based on subwavelength gratings was published many years ago, but has only recently reached commercial viability for projection display applications.

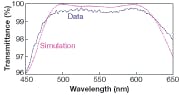

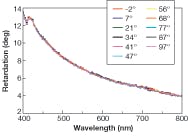

The all-dielectric subwavelength trim retarder consists of a glass substrate into which a nanoscale grating is etched. The trenches of the grating structure are filled with a nanolaminate material consisting of titanium dioxide (TiO2) and silica (SiO2). The design and deposition of the monolayers enable precise control of the refractive index of the fill material, in a range from 1.46 to 2.35 (see Fig. 4).5Subwavelength prepolarizers, polarizing beamsplitters, and trim retarders have been demonstrated to enhance the contrast of LCOS projection displays. They offer the added advantage of compact size and environmental durability. Future applications for subwavelength optical elements will include flexible polarization and phase-management devices for displays.

REFERENCES

1. D. Hansen, E. Gardner, R. Perkins, M. Lines, and A. Robbins, SID 02 Digest, 730 (2002)

2. J. Wang et al., Appl. Phys. Lett. 89(14) 102 (2006).

3. M. Born and E. Wolf, Principles of Optics, 6th ed., Chapter 15, Macmillan, New York (1964).

4. M. Born and E. Wolf, Principles of Optics, 6th ed., Chapter 14, Macmillan, New York (1964).

5. J. Wang et al., Optics Letters 30(14) 1864 (2005).

Jian Wang is chief technology officer, Nada O’Brien is vice president product development, and Maria Light is director display and imaging at NanoOpto, Somerset, NJ 08873; e-mail: [email protected]; www.nanoopto.com.