Spinning meta-optics for spectro-polarimetric thermal imaging?

Thermal imaging is currently used within a wide range of applications, such as security, thermography, night vision, medical diagnostics, and remote sensing. One big drawback: traditional thermal imaging systems tend to suffer from significant information loss, which results in blurry thermal images.

But Professor Zubin Jacob’s research group at Purdue University (West Lafayette, IN) came up with a way to address it earlier by creating heat-assisted detection and ranging (HADAR), which enables detailed texture in thermal imaging—and allows machine perception through the darkness of night as if it’s broad daylight.

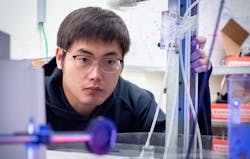

“HADAR requires spectral resolution within the longwave-infrared spectrum, and the concept is similar to how human eyes perceive red, green, and blue (RGB) colors—except HADAR detects similar ‘colors’ within the invisible infrared spectrum,” explains Xueji Wang, a postdoctoral researcher, who works with Jacob and thermal photonics. “Conventional thermal imagers with spectral resolution are generally bulky and delicate, mainly due to their dependence on large filter wheels or interferometers.”

Recent significant advancements within the field of meta-optics are, thankfully, making it easier to capture spectral information in a more compact and effective manner at the visible range of the spectrum.

“Our current work applies these advancements to the infrared—introducing a metasurface-based approach to achieve spectro-polarimetric thermal imaging,” says Jacob. “Our goal is to advance the broader adoption of HADAR and elevate it to the level of established technologies like radar, LiDAR, and sonar.”

To do this, the team developed a meta-optics technique for advanced thermal imaging. “Meta-optics refers to the use of engineered optical materials, known as metamaterials, to manipulate light at the subwavelength scale,” says Wang.

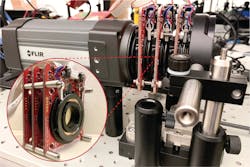

The team’s meta-optic technique extends beyond traditional infrared thermal cameras, which primarily capture the intensity of thermal radiation, by also revealing spectrum and polarization details to provide a more comprehensive understanding of imaged objects (see Fig. 1 and video).

Spinning metasurfaces meet novel computational algorithms

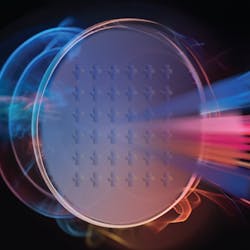

The team designed metasurfaces—ultrathin structured surfaces that manipulate light in complex ways—crafted from zinc selenide (ZnSe), a material highly efficient in transmitting infrared thermal radiation, then topped them with golden microstructures that interact with incoming radiation to enable spectral and polarimetric separation.

“By stacking and physically rotating—spinning—these metasurfaces, we break down thermal light into its spectral and polarimetric components,” says Wang. “We then integrate this system with a standard thermal imaging sensor to enable image-based recording of this complex data. Finally, our computational algorithms analyze this data and provide detailed spectral and polarization information for every pixel within the thermal images.”

Their technique stands out, in large part, because of its compactness, robustness, and versatility (see Fig. 2). Traditional spectral thermal imagers are often bulky benchtop systems that rely on large filter wheels or interferometers, which makes them unsuitable for portable devices.

“Our approach creates a much smaller module, roughly the size of 10 cm × 10 cm × 10 cm,” says Wang. “And the spinning operation of our design can be efficiently executed with standard rotators—meaning it’s more robust than the delicate, wavelength-scale mirror movements required in interferometers. And it makes our system adaptable to a broader range of applications due to its enhanced portability and robustness.”

The biggest challenge along the way—and the key innovation behind the team’s work—was developing large-area metasurfaces. “We designed these metasurfaces to generate desired infrared responses. In parallel, we developed a complex fabrication process to create large-area devices (1-in. diameter) suitable for imaging applications,” says Wang.

It’s important to note that integrating these large-area meta-optical devices with computational imaging algorithms plays a crucial role in this work. This combo enables the efficient reconstruction of the thermal radiation spectrum, which led to a more compact, robust, and effective spectro-polarimetric thermal imaging system than previously achievable.

The team demonstrated that when their system is combined with a commercial thermal camera, it can classify various materials—which is typically challenging for conventional thermal cameras.

Broad range of applications ahead

The team’s system has a broad range of applications—particularly where detailed thermal images are required. “In security, for example, it could revolutionize airport systems by detecting concealed items or substances on people,” says Jacob. “Its ability to distinguish temperature variations and identify materials based on their spectro-polarimetric signatures can boost both safety and efficiency.”

Spectral thermal imaging can also be used for predictive maintenance because it can more accurately identify overheating machinery before it fails. In medical applications, it can assist diagnosis by accurately revealing body temperature variations.

“Our system’s compact and robust design enhances its suitability for diverse environmental conditions—which makes it beneficial for autonomous navigation,” says Wang. “Traditional autonomous navigation relies heavily on RGB cameras, which struggle in challenging conditions like low light or bad weather.”

Spectro-polarimetric thermal cameras can provide vital information for each of these difficult scenarios—offering much clearer images than RGB or conventional thermal cameras. “Once we achieve real-time video capabilities, this technology will become as integral to autonomous vehicles as LiDAR, radar, and sonar, and significantly enhance scene perception and overall safety and rescue operations because thermal cameras can locate individuals in challenging conditions by detecting the heat of the human body,” says Jacob.

Metasurface design work

Next up? Focus on enhancing spectral resolution, transmission efficiency, and the speed of image capture and processing. “We plan to improve our metasurface design for more complex light manipulation to achieve higher spectral resolution,” says Wang.

The use of metasurface stacks also limits transmission efficiency and signal-to-noise ratio, which currently restricts the researchers’ demonstrations to high-temperature objects. “We aim to extend this to room-temperature imaging by using improved materials, metasurface designs, and techniques like antireflection coatings,” Wang adds. “Another goal is to develop faster rotating mounts for real-time video capture. These advancements are the keys to moving this technology from the lab to commercial use.”

FURTHER READING

X. Wang, Z. Yang, F. Bao, T. Sentz, and Z. Jacob, Optica, 11, 1 (2024); doi:10.1364/optica.506813.

F. Bao et al., Nature, 619, 743–748 (2023); https://doi.org/10.1038/s41586-023-06174-6.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.