Clean, affordable energy supply requires balancing technology and regulation

The challenges of dealing with climate change and the promising opportunities for action are well known. That's why the world spent a total of $755 billion on reducing emissions in 2021. Our efforts to scale up and invest in clean energy technologies over the next 20 years will determine life on Earth for the next hundred. Data, analysis, and science must back everything we do.

Carbon dioxide levels are thought to be at their highest levels in human history, and while many agree the goal of 1.5°C by 2030 is arbitrary and now unachievable—working to prevent every 0.1°C rise can still give us hope.

Decarbonizing the energy sector

Thirty years ago, 197 countries from around the world got together to ban the gases damaging the Earth's ozone layer. Today, more than 99% of ozone-depleting substances have been phased out, and the ozone layer is on a path to recovery.

Now we need to unite to combat an even more significant threat.

The Extinction Rebellion protests and passionate pleas of Greta Thunberg for world leaders in politics and industry to take action on what they describe as “the unprecedented global climate emergency” have brought a greater sense of urgency to the energy transition.

Britain's manufacturers are leading the charge toward net zero and decarbonizing their businesses as the sector moves to slash greenhouse gas emissions, cut energy use, and switch to renewable and sustainable energy sources.

Manufacturers have moved the decarbonization of their businesses up the priority ladder despite unprecedented economic challenges, with eight in 10 companies saying it is now of high or medium importance. Companies are accelerating efforts to decarbonize due to rising energy costs, the need to do the right thing, and the rising cost of raw materials.

The world is facing simultaneous inflation, national security, and climate crises, all caused by our dependence on high-cost, insecure, polluting fossil fuels with volatile prices. Ambitious policies to accelerate the transition to a clean energy future as quickly as possible are urgently needed for climate reasons. They can save the world trillions in future energy costs.

Monitor, manage, minimize

Every day, tons of carbon dioxide, methane, nitrous oxide, and other unnoticed emissions leak into the atmosphere, untracked and unmeasured—but not without impact.

The global economy loses more than $8 trillion annually, according to The World Bank. But action to identify its presence and catalog its makeup and levels still lags.

As companies in high-emissions sectors strive to comply with environmental and safety regulations imposed by governments and regulatory agencies, emissions monitoring and quantifying technologies are in high demand.

Many companies struggle to understand the material impacts their stated industrial decarbonization goals will have on their valuations, operations, employees, and markets over the next few years.

Chief sustainability officers (CSOs) and their operations and engineering peers are turning to automation technologies, software, and analytics to deliver proven, short-term wins that will help propel enterprise-wide programs to meet their sustainability targets. While companies invest in new, cleaner energy alternatives, they must also look for ways to cut emissions in the short, mid, and long term. Specifically, they are evaluating emissions management technologies available today to prevent leaks in the first place, produce fewer emissions by using lower carbon intensity sources, and run processes with more efficient combustion and lower emissions.

The release of controlled and uncontrolled emissions ranging from greenhouse gases to toxic leaks has been a persistent challenge for decades. Given industrial manufacturing and power generation account for nearly 50% of the world's greenhouse gas emissions, these sectors' CSOs are under significant pressure to make changes that measurably impact emissions.

Common sense

Many companies are offering measuring technologies in the market for measuring emissions. Infrared (IR) gas-detection filters, which are used with an IR beam to detect and quantify gases present in the atmosphere, sit at the very heart of so many of these devices.

IR emitters within the sensor generate beams of IR light. After passing through a sampling chamber, a filter in front of the detector blocks out light not at the desired wavelength. In contrast, the sensor measures the intensity or attenuation. This is then used to determine the concentration based on the absorption of IR radiation as it passes through a volume of the gas.

Among their benefits are fast response times and accurate results, while not requiring oxygen or external gases to operate. Technological advances have also resulted in detectors that continuously monitor combustible gases and vapors within the lower explosive limit and provide alarm indications. These can be deployed within oxygen-deficient or enriched areas, require little calibration, and are immune to sensor poison, contamination, or corrosion.

Globally environmental regulatory authorities require manufacturing industries to monitor their pollutant emission rates. The most common means of measuring emissions is via continuous emissions monitoring systems, which are a packaged system of gas analyzers, gas sampling systems, temperature, and flow and opacity monitors; these are then integrated into a system for data acquisition.

Accurate, reliable monitoring of smoke, dust, and particulate emissions from industrial applications helps ensure safer and more efficient manufacturing and combustion processes. It is also critical to protect local communities' safety, health, and wellbeing and maintain ambient air quality standards to comply with environmental regulations.

Empowering decision-making

By embracing data, the industry can be empowered to make more informed decisions to improve processes and drive efficiencies. The net result: more sustainable performance, heightened productivity, better quality products, reduced energy usage, lower emissions, and less landfill. That's the sort of future we all need to invest in.

Technology is now more affordable and accessible than ever. Connected gas detection isn't the technology of the future anymore. It's right here and more money-saving, sustainable, and straightforward than you think.

With more than 35 years’ experience in thin film design and manufacture, we develop custom solutions for low-volume prototyping to full production scale-up of the most demanding optical coating applications.

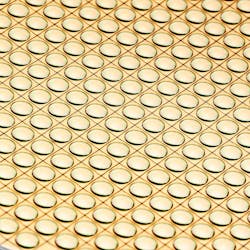

We work closely with our customers through a consultative approach to develop custom IR designs that balance performance reliability with production efficiency. In doing so, we can offer a range of bandpass optical filters ideally suited to environmental, gas detection, and analysis applications, with a center wavelength anywhere on the near-infrared (near-IR) to far-infrared (far-IR) spectrum with steep-edge and deep blocking capability (see photos).Collective endeavor

When scientists alerted the world that there was a gaping hole in the ozone layer due to man-made chemicals emitted into the atmosphere, political and environmental leaders came together to address the problem.

It's incumbent on all of us across our industries to deliver improvements to efficiency, embrace technological advances, streamline our work, and ultimately reduce the environmental impact of our activities.

Our new mantra should be that every fraction of a degree, every year, and every choice matters.

About the Author

Mark Naples

Mark Naples is the managing director for Umicore Coating Services (Dundee, U.K.).