Glass gradient-index optics are 3D-printed by mixing two precursors, then densifying

Rather than the homogenous hunk of glass that makes up a conventional optical lens, a gradient-index (GRIN) optic has a refractive index that varies as a function of position inside the optic; this adds an extra degree of freedom that can simplify the shape of the optic or add extra capabilities. For example, a common type of GRIN lens is a rod with a radially varying index and flat endfaces. Fabricating GRIN optics commonly involves diffusing a substance into glass to create the index gradient; this is a time-consuming and perhaps not entirely deterministic process. Now, researchers at Lawrence Livermore National Laboratory (LLNL; Livermore, CA) are using multimaterial 3D printing to create tailored GRIN optics that could make for better military specialized eyewear and virtual reality goggles. The new technique could achieve a variety of conventional and unconventional optical functions in flat glass components, offering new optical design versatility in environmentally stable glass materials.

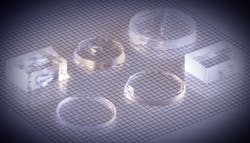

The team was able to tailor the gradient in the material compositions by actively controlling the ratio of two different glass-forming pastes or “inks” blended together inline using the direct ink writing (DIW) method of 3D printing. After the composition-varying optical preform is built using DIW, it is then heated to remove all solvents and organic compounds, densified to glass, and then finished using conventional optical polishing. For example, around 300 μm was removed from experimental flat GRIN optics via grinding and polishing to remove texture from print lines and to achieve surface microroughness of better than 1 nm root mean square (RMS).

The index gradient arises from the varying concentrations of titania in the mix of silica nanoparticles deposited via the 3D printing process. The two different viscoelastic inks are deposited via nozzles—the smaller the nozzle, the smoother the index gradient, but also the higher the pressure needed to force the ink from the nozzle. The researchers used a conical nozzle with a 610 μm diameter at the outlet. The final dense components were about 11 mm in diameter and 1–5 mm thick. Performance of a component with a parabolic concentration profile was about 5X the diffraction limit (cylindrical lenses were also fabricated). “Although demonstrated for GRIN, the approach could be used to tailor other material or optical properties as well,” says Rebecca Dylla-Spears, lead author of the paper. Reference: R. Dylla-Spears et al., AAAS Sci. Adv. (2020); doi:10.1126/sciadv.abc7429.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.