In a collaboration that bridges academic research and commercial innovation, scientists from the LUMINOUS! Centre of Excellence at Nanyang Technological University, Singapore (NTU Singapore) have partnered with engineers at PureFize Technologies in Sweden to create a portable device called EcoLoc that keeps refrigerated food safer and fresher.

The innovation at the heart of the device? A compact chip that emits UV light that eliminates microorganisms on food.

Shining a light on environmentally friendly UV disinfection

Mercury lamps have been used as sources of UV light for more than 100 years. But because they contain mercury, these lamps pose health and environmental safety risks when damaged or discarded. As a result, these light sources cannot be used safely for applications within close proximity of people. The lamps are also bulky and take a long time to warm up, which makes them impractical for certain uses.

The Minamata Convention on Mercury, adopted in 2013, also calls for a global phaseout of the metal within consumer products to protect human health and the environment from the adverse effects of mercury.

Unlike lamps that generate UV light by vaporizing mercury, the new UV chip generates UV light through a process called cathodoluminescence. It contains two electrodes: a zinc oxide (ZnO) cathode and an anode coated with a material that emits mainly UVC (shortwave UV) when excited by electrons. By applying voltage, electrons are emitted from the cathode and accelerated within a vacuum by the electric field toward the anode—and UV light is emitted when it’s hit by the electrons.

The chip emits a broad-spectrum of UV wavelengths from 250 to 350 nm, peaking at 262 nm and extending into the UVB (280–315 nm) and UVA (315–400 nm) regions to target bacteria, viruses, and fungi. This combination leverages UVC to disrupt DNA, while UVB and UVA penetrate and destroy difficult-to-eradicate communities of microorganisms known as biofilms and cellular components such as proteins and lipids.

The UV chip functions at temperatures from -20° to 100°C and can be turned on and off instantly, which is crucial for applications that require immediate disinfection, such as the irradiation of food.

Eliminating microorganisms with the flip of a switch

Approximately one-third of all food produced globally is wasted, according to the United Nations Food and Agriculture Organization, with microbial spoilage being one of the main causes of food wastage and households accounting for about half of the food discarded. Pathogens in food can also cause foodborne illnesses.

Thankfully, consumer-friendly disinfection solutions may help reduce food waste and the spread of foodborne illnesses. Tests show that the disinfection efficiency of the UV chip is comparable to existing mercury lamps. It successfully neutralizes major pathogens, including Escherichia coli, Pseudomonas aeruginosa, and Legionella pneumophila, which are associated with foodborne illnesses and contaminated water supplies. The UV light emitted by the chip also inactivates SARS-CoV-2, the virus that causes COVID-19.

The chip is now available in a commercial handheld device called EcoLoc, which is used with a specially developed food container lid. Its lid, manufactured by PureFize subsidiary EcoLoc, is compatible with the IKEA series of 365+ food storage containers.

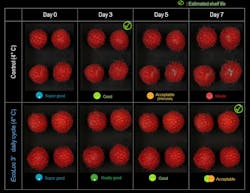

How does it work? Simply switch EcoLoc on for a few minutes before putting food inside the refrigerator or use it daily. It extends the shelf life of perishable foods such as bread, fruits, vegetables, and meats to almost a week with minimal changes in taste and odor.

The chip is a “breakthrough for health and safety because it can eradicate harmful food spoilage microorganisms and reduce the spread of infectious diseases such as COVID-19,” says Senior Research Fellow Vijay Kumar Sharma of NTU’s School of Electrical and Electronic Engineering and LUMINOUS!, who was the first author of the study. “It will also contribute to a greener future by reducing the amount of food waste generated.”

Academia meets industry

The development of the chip is the culmination of a 10-year partnership between NTU and PureFize Technologies (formerly LightLab Sweden).

Several patents and technical disclosures have been filed and awarded for the chip.

“We saw an untapped opportunity in the UV disinfection market and combined our expertise in nanotechnology, optoelectronics, and material science with product development know-how, commercialization strategies, and consumer insights from PureFize Technologies,” says Hilmi Volkan Demir, director of LUMINOUS! and professor at NTU’s School of Electrical and Electronic Engineering, School of Physical and Mathematical Sciences, and School of Materials Science and Engineering, who led the research and was the senior author of the study.

The broad-spectrum UV technology “combats biofilm formation, and we’ve shown that it can be operated within small, confined spaces without the need for cooling. It complements the range of available UV technologies on the market very well,” says Rune Torbjörnsen, CEO of PureFize Technologies.

FURTHER READING

V. K. Sharma et al., Adv. Opt. Mater., 9, 15, 2100072 (Aug. 4, 2021); https://doi.org/10.1002/adom.202100072.

About the Author

Daphne Ng

Dr. Daphne Ng is the science communication lead at Nanyang Technological University, Singapore’s Corporate Communications Office.