Tanaka begins sample shipments of new fused-silica 'lids' and sealing technology for deep-UV LEDs

Precious-metals specialist Tanaka Kikinzoku Kogyo (Tokyo, Japan) has begun shipping samples of its "SKe-Lid," a newly-developed glass lid (a "lid" is actually the transmitting face for a hermetically-sealed ceramic LED can) made of quartz with gold-tin (AuSn) solder sealant for use with deep-UV LEDs.1 Tanaka's metals experience is behind the development of the new sealant.

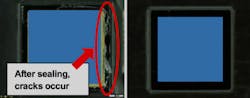

Deep-UV LEDs are a next-generation light source expected to replace mercury lamps and have various applications including water disinfection in industry, removal of marine biofouling, and air-disinfection systems in health care. When used in combination with quartz glass (fused silica), which has high transmissivity at deep-UV wavelengths, and AuSn sealant, which has excellent air-tightness and durability, however, problems with cracking of the quartz glass and metallization separation can occur.2

(If deep-UV LEDs are manufactured using conventional resin sealants, the UV light causes degradation of the resin sealants, resulting in deterioration of device properties and lifespan.)

Tanaka's new glass lids, made of fused silica with AuSn solder, use technologies developed by Tanaka that properly control the shape and dimensions when applying the AuSn sealant to the quartz glass, making it possible to control cracking and metallization separation. Higher yields are expected to contribute to improved productivity and lower costs. The SKe-Lid cover is compatible with glass with AR coatings.

Tanaka says the SKe-Lid cover has these advantages over conventional deep-UV LED lids:

--When using quartz glass with AuSn, the AuSn solder is already applied to the glass, facilitating its positioning relative the ceramic package during sealing

--The technology prevents the formation of cracks during sealing of AuSn to quartz glass and the ceramic packaging

Tanaka says that SKe-Lid is expected to contribute to higher productivity and lower costs of final products in the deep-UV LED market, and that AuSn sealing will likely be used in semiconductor lasers also, which require high reliability and durability, and devices that require transparent covering materials such as automotive sensors.

SKe-Lid was developed with cooperation from Kyocera, Yamamura Photonics, and Asahi Glass, which provided the glass material and ceramic package material, and Cross Osaka, which performed the seal testing.

Source: http://www.acnnewswire.com/clientreports/598/180402_EN.pdf

REFERENCES:

1. Deep ultraviolet: Also referred to as UVC. Has a wavelength from 250 nm to 280 nm. Has strong disinfecting effects.

2. Metallization: A technology for coating nonmetallic surfaces with a metal. Ceramics and other materials that have been metallized form an electric circuit and are used during soldering and for different applications.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.