LaserDuo laser cutting machine is 'open source'; you build it yourself from drawings

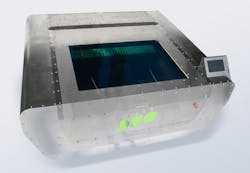

Researcher Daniele Ingrassia and his team at the FabLab, Rhine-Waal University of Applied Sciences (Kleve, Germany), have developed the LaserDuo, a dual-wavelength laser cutter that includes a 130 W CO2 laser and a 75 W Nd:YAG laser and which cuts at a speed of up to 800 mm/s at a resolution of 25 microns (1000 dpi). Working volume is 1500 x 1000 x 500 mm. The cutter is fully enclosed.

The LaserDuo can cut wood, plastics, cardboard, cloth, leather, marble, and metals including steel and stainless steel, brass, copper, aluminum, magnesium, and zinc-plated steel. What makes this laser cutter stand out is that it is "open source," meaning that all mechanical drawings, electronics schematics, etc. are freely available. This also means that you build the laser cutter yourself. However, do-it-yourselfers will not be building these machines in their basements unless they can build their own microcontroller board from plans and have the capability of fabricating complex mechanical components or getting them fabricated. (Some DIYers do have these capabilities!)

The open-source nature of this project means that high schools and colleges could build these laser cutters for their own use in labs, or offer courses that include building a laser cutter. "Open source" also means that a commercial outfit could build these, and even modify the plans, as long as the original source of the plans is attributed.

For more info, see http://laserduo.com.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.