An international research team of scientists from Nanyang Technological University, Singapore (NTU Singapore), Yale University, and Imperial College London has designed a new way to build high-powered lasers that could result in stable beams, overcoming a long-standing limitation in conventional lasers. The scientists have developed a unique D-shaped laser that is able to regulate the light emission patterns and eliminate such laser instabilities to potentially reduce the degree of fluctuations in the laser output.1 In high-powered lasers such as those used in materials processing, large-scale displays, laser surgery, and lidar, laser instabilities often occur that limit their usage. This instability poses no problems for simple applications such as laser pointers, but becomes a serious issue for lasers operating at high power.

Chaos battles instability

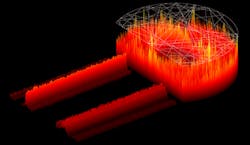

To suppress this instability, the international researchers created a D-shaped laser cavity that causes light to bounce off the walls of the cavity in a chaos manner that, however, results in a stable light stream. The research was done on a laser diode, but the joint research team believes their findings could be extended to other types of lasers, including gas lasers and solid-state lasers. Most traditional laser devices take on a cuboid shape, with mirrors placed parallel to each other on both ends to allow light to bounce back and forth between the mirrors. This seemingly uniform bouncing however leads to laser instability, especially in high-powered lasers. Yale professor Hui Cao, the principal investigator who led the international study, said previous strategies to reduce such interference have usually involved reducing the power of the laser.

"As a result, none of the previous approaches are scalable to the power levels required for practical applications," she says. To tackle this chaos, NTU associate professor Wang Qijie led his two PhD students to create the D-shaped laser cavity. Wang says that imaging applications such as next-generation microscopes, laser projectors, and biomedical imagery are the end goal for the joint research team. "We have found that a D-shaped laser cavity is easy to fabricate, and is effective in significantly reducing the problematic laser instabilities. Our next step will be to find out if there are other cavity shapes that could make the laser more efficient," he says.

(Note: this article has been edited to correct an error: Hui Cao, who is a woman, was initially referred to as "he." For that I apologize, both to Dr. Cao and to our audience. -- John Wallace)

REFERENCE:

1. Stefan Bittner et al., Science (2018); doi: 10.1126/science.aas9437.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.