Gaithersburg, MD--Using a spark-based UV light source, a physicist at the National Institute of Standards and Technology (NIST) has helped NASA scientists successfully position a crucial UV sensor inside a space-borne instrument to observe a "hidden" layer of the Sun where violent space weather can originate.

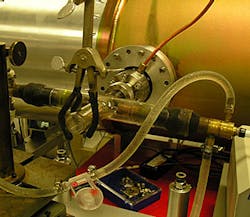

The "sliding-spark source" consists of a pair of graphite electrodes with a quartz surface in between. A spark created by the electrodes glides along the quartz surface, controllably producing the desired wavelengths of UV light from ionized carbon.

The SUMI instrument

The Solar Ultraviolet Magnetograph Investigation (SUMI) device is a rocket-borne instrument that watches the Sun for signs of events that can create violent episodes of increased solar wind, or "space weather."

Sunspots create strong electromagnetic fields and release charged particles into space. As these particles and fields pass through the Sun's "transition region" 5,000 km above the surface, they can gather considerable steam, resulting in space weather that can damage Earth-orbiting satellites and disrupt electronic communications.

The powerful magnetic fields in the transition region can be studied indirectly, by observing the UV light emanating from that region. The fields slightly shift the wavelengths of UV light released by ions in their vicinity. Measuring the wavelength shifts yields information on the magnetic field's strength.

However, this can't be done from the Earth's surface, where the atmosphere absorbs the UV light, so a team at NASA Marshall Space Flight Center (Huntsville, AL) constructed a SUMI to take pictures of these magnetic fields from space.

SUMI observes shifts in the well-known wavelengths of UV light emitted by magnesium and carbon ions. But the instrument's optics must be precisely aligned such that the wavelengths in its spectrally spread beam properly overlay the instrument's detectors.

"The issue becomes how to align the complicated optics in the instrument so that the magnesium and carbon lines are recorded on its detectors," says NIST physicist Joseph Reader. "The solution is to get a light source that can produce these same lines in the laboratory."

Readily available lamps can simulate the UV light from the singly ionized magnesium, but generating the UV light from triply ionized carbon (carbon with three electrons removed) is difficult. Enter NIST's sliding-spark source.

On July 30 of this year, SUMI was successfully launched from White Sands, N.M. It rose 320 km into space and observed sunspot 11092 for about 6 minutes before parachuting back to earth. The Huntsville team is analyzing the data it obtained.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.