Quantum-dot mode-locked laser on silicon transmits data at 4.1 Tbit/s

A group at the University of California (UCSB) has created a high-channel-count 20 GHz passively mode-locked quantum-dot laser directly grown—for the first time, to the group's knowledge—on a silicon substrate.1 With a proven 4.1 Tbit/s transmission capacity, the micron-sized laser leaps an estimated full decade ahead from today's best commercial standard for data transmission, say the researchers, which is currently reaching for 400 Gbit/s on Ethernet. The technology is the latest high-performance candidate using the tried-and-true wavelength-division-multiplexing (WDM) technique.

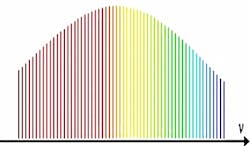

"We want more coherent wavelengths generated in one cheap light source," says Songtao Liu, one of the researchers. "Quantum dots can offer you wide gain spectrum, and that’s why we can achieve a lot of channels." The laser is passively mode-locked to prevent noise from wavelength competition in the laser cavity and stabilize data transmission. Mode-locking produces a frequency comb with a 3 dB optical bandwidth of 6.1 nm. The laser is intended to become part of silicon electronic and photonic integrated circuits (EPICS).

While silicon is a good material for the quality of light it can guide and preserve, and for the ease and low cost of its large-scale manufacture, it's not so good for generating light. "If you want to generate light efficiently, you want a direct-bandgap semiconductor," says Liu. "Silicon is an indirect band-gap semiconductor."

The quantum dot laser, grown on silicon molecule-by-molecule at UCSB's nanofabrication facilities, is a structure that takes advantage of the electronic properties of several semiconductor materials for performance and function (including their direct bandgaps), in addition to silicon's own well-known optical and manufacturing benefits. Since John Bowers and his UCSB group a decade ago demonstrated the world s first hybrid silicon laser (an effort in conjunction with Intel), the silicon photonics world has continued to create higher efficiency, higher performance technology while maintaining as small a footprint as possible, with an eye on mass production.

The quantum dot laser on silicon, Bowers and Liu say, is state-of-the-art technology that delivers the superior performance that will be sought for future devices.

REFERENCE

1. Songtao Liu et al., Optica (2019); https://doi.org/10.1364/OPTICA.6.000128.

Source: https://www.news.ucsb.edu/2019/019345/glimpse-future

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.