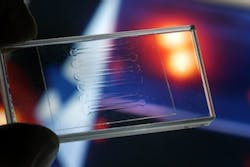

Aachen, Germany--Until now, it has been impossible to use laser welding to fuse two transparent plastic components together. But researchers have succeeded in circumventing this hurdle by choosing the right wavelength. The new welding process has great potential for bioanalytics (lab-on-a-chip devices).

Previously, there had been little freedom of choice: the upper joining part had to be transparent to permit the laser to shine through unimpeded while the lower joining part absorbed the radiation. This usually meant soot particles had to be blended into the plastic. These particles absorb the energy of the laser beam, allowing fusion heat to reach the upper joining part. “Up until now, you usually had to choose a single plastic combination: transparent and black,” says Alexander Olowinsky, project manager at the Fraunhofer Institute for Laser Technology ILT. “There are lots of applications--in medical technology, for instance--where what’s needed is a combination of two transparent plastics. The industry now also makes infrared absorbers that are nearly transparent, but these are not only very expensive but also have a green-yellowish tint to them. So our goal was to find a way to get the job done completely free of absorber materials.”

To accomplish this, researchers studied the absorption spectra of a range of transparent polymers in search of wavelength ranges within which plastic absorbs laser radiation. Then the scientists tested and perfected the laser systems to match.

The researchers’ most promising results were achieved at a wavelength of around 1700 nm. “This is the peak welding-efficiency range,” Olowinsky says. Nevertheless, the researchers are also continuing work on the EU Commission-sponsored “PolyBright” project (www.polybright.eu) in search of the combination of the best absorption bands and light sources. “The result has to be the most cost-effective laser system possible that can execute high-precision welding tasks at the highest possible speed.”

Subscribe now to Laser Focus World magazine; it’s free!

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.