Silver-diamond composite to efficiently cool semiconductor devices

Atlanta, GA--A solid composite heat-conducting material created by scientists at the Georgia Tech Research Institute (GTRI) has a thermal conductivity that is higher than any metal and takes advantage of the properties of diamond, which is the most thermally conductive material known. (Single-crystal diamonds are sometimes used as "heat spreaders" for semiconductor lasers.) The silver-diamond composite could be of great use in photonic components such as high-power laser diodes and IR semiconductor detectors, although it is being aimed at cooling wide-bandgap semiconductors planned for next-generation phased-array radars.

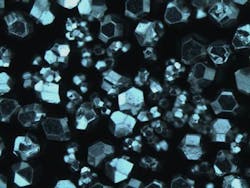

Diamonds set in silver

The material is made of very small particles of diamond in a matrix of silver. Unlike single-crystal diamond, the small particles are relatively inexpensive. The silver, which is in itself very conductive (400 W m-1 K-1), although not nearly as conductive as diamond (2000 W m-1 K-1), serves to bond the loose diamond particles into a stable matrix, allow precise cutting of the material to form components of exact sizes, and create a thermally effective interface between the diamonds.

One of the most important qualities of the silver-diamond composite is that its coefficient of thermal expansion can be tailored to match the semiconductor that is being cooled. This is crucial, because otherwise the heat-conducting layer would delaminate from the semiconductor as temperature changes.

The researchers want to use the composite as a thermal shim with thicknesses of 250 microns or less. Some versions of the composite are up to 85% diamond. The thermal shims made so far are very small, making in-depth testing (which would help to explain the material's performance in terms of materials science rather than just in terms of performance results) difficult so far—but the GTRI group is evaluating several testbed technologies that hold promise for detailed thermal-conductivity analysis.

Subscribe now to Laser Focus World magazine; it’s free!

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.