Diffraction-limited organic lasers have inkjet-printed gain media cheap enough to be disposable

In a process that could lead to lasers with gain media that are so low in cost as to be virtually free, scientists from Université Paris 13 and CNRS (Villetaneuse, France), Semilab Semiconductor Physics Laboratory (Budapest, Hungary) and the Ecole Nationale Supérieure des Mines de Saint Etienne (Gardanne, France) have developed a type of laser core that is fabricated using inkjet printing.1 The thin-film organic external-cavity vertically emitting laser capsules can be made fully disposable.

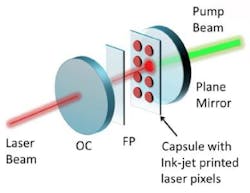

The inkjet-printed laser capsules are made of an optical host matrix of EMD6415 commercial ink with a refractive index of 1.5, and incorporating a standard laser dye such as Pyrromethene 597 or Rhodamine 640. near the capsule is an intracavity polymer-based Fabry-Perot etalon that allows the laser output to be continuously tunable from 570 to 670 nm. (The laser mirrors and pump are external to the laser capsule.)

Cost: a few cents each

While organic lasers are inexpensive, one obstacle that has held them back is the fact that they degrade relatively quickly, but that hurdle might be less daunting if the lasers are so cheap they could be tossed when they fail. The researchers estimate the capsules could be produced for only a few cents each.

"By piezoelectric inkjet printing, you print 'where you want, when you want,' without wasting raw materials," says Sébastien Sanaur, an associate professor at the Ecole Nationale Supérieure des Mines de Saint-Étienne.

The technique doesn't require masks, can be done at room temperature, and can print onto flexible materials.

The team used two different types of dyes to produce laser emission ranging from yellow to deep red. Other dyes could cover the blue and green part of the spectrum, they predict. With further development, the inexpensive inkjet-printed laser could send data over short plastic fibers and serve as a tool for analyzing chemical or biological samples.

Source: http://www.eurekalert.org/pub_releases/2016-05/aiop-itd042716.php

REFERENCE:

1. Oussama Mhibik et al., Journal of Applied Physics (2016); http://dx.doi.org/10.1063/1.4946826

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.