INTERBAND CASCADE LASERS: ICLs open opportunities for mid-IR sensing

LARS NÄHLE, LARS HILDEBRANDT, MARTIN KAMP, and SVEN HÖFLING

The use of spectroscopy in research and industry has grown continuously in recent decades. Industrial process control, gas-concentration monitoring for work safety, and environmental and atmospheric gas tracing are just a few of the fields in which spectroscopy has become important. Increasingly, tunable-laser absorption spectroscopy (TLAS) is being implemented for such applications.

Compared to other techniques, TLAS has some outstanding advantages—for example, regarding ruggedness of the sensor and the accuracy and speed of measurement. Using singlemode semiconductor lasers, which can be rapidly tuned by varying the current, gas species can be selectively sensed in real time with sensitivities down to the parts-per-million or even parts-per-billion level. These advantages make the use of TLAS a very active area of research.

Major improvements in sensing speed, noise reduction, and sensor miniaturization in a TLAS measurement are achieved by using the strongest absorption bands of the gases being measured. For a huge number of industrially and environmentally significant gas species, these bands are in the mid-infrared (MIR) wavelength range of around 3–6 μm. Here, they can have absorption strengths several orders of magnitude higher than those in other infrared (IR) areas.

The strongest absorbing features of prominent molecules such as carbon dioxide (CO2), nitric oxide (NO), water (H2O), and most hydrocarbons (for example, methane [CH4]) can be found in this IR window. For TLAS, singlemode laser sources emitting continuous-wave (CW) in the 3–6 μm range with reasonable power consumption and operating at ambient temperatures had previously not been commercially available. This gave rise to the wavelength range being referred to as the "gap" in spectroscopic gas sensing.

nanoplus first entered this gap by introducing CW singlemode distributed feedback (DFB) lasers operating at wavelengths up to 3.5 μm in 2012 (see "DFB laser diodes expand hydrocarbon sensing beyond 3 μm"; http://bit.ly/zN2FTl). Now, the company has developed CW singlemode DFB interband-cascade lasers (ICLs) emitting in the 3–6 μm region, effectively closing this gap.

DFB laser technology

nanoplus produces laser sources for gas sensing applications in the visible, near-IR (NIR), and mid-IR (MIR) wavelength ranges.1 For the development of the new 3–6 μm laser sources, the company uses a gallium antimonide (GaSb)-based ICL design. Performances of different laser designs advancing into the 3–6 μm gap region from the lower and higher wavelength sides are compared (see Fig. 1).

Color-coded in black are GaSb-based type-I transition singlemode DFB lasers operating in CW mode at room temperature (RT). A strong rise in threshold power density moving toward and crossing the 3 μm barrier can be observed. Due to enhanced Auger recombination in the structures, very high power densities greater than 10 kW/cm2 are inevitable, in particular for emission near and beyond 4 μm. Approaching from the high-wavelength side, the situation is similar for intersubband-transition DFB quantum-cascade lasers (QCLs) based on indium phosphide (InP; red); QCLs also experience power densities ranging beyond 10 kW/cm2.

Maintaining CW operation at RT and reasonably low energy consumption levels in TLAS applications is therefore not feasible with these approaches. Depicted in green (star) is the power-threshold value of the most recently published 3.8 μm DFB ICL in CW operation at RT.2 Compared to the two aforementioned approaches, the type-II-transition ICL has a threshold power more than an order of magnitude lower—below 1 kW/cm2.

Pulsed-operation results of broad area (BA) ICLs from 3–6 μm are depicted as squares. It becomes clear that interband-cascade technology is ideal for high-performance lasing in the entire range from 3–6 μm due to relatively wavelength-independent threshold powers. The ICL approach is thus optimal for emission in the MIR wavelength range, combining high performance with reasonably low power consumption.

Based on recent ICL developments by the Technische Physik, University of Würzburg, DFB lasers in the entire 3–6 μm range are fabricated at nanoplus.3 The devices are manufactured without epitaxial overgrowth, avoiding impairment of laser performance due to the insertion of patterning-induced defects within the laser layers.

In a first step, laser waveguides with an incorporated grating structure are defined by electron-beam lithography. This high-precision step enables the emission wavelengths of the subsequent DFB devices to be precisely adjusted down to the nanometer. By this means, the lasers are designed precisely according to their spectroscopic applications.

The emitter structures are then defined in a single deep-cut, dry-etch step below the active cascades (on the order of 3 μm), forming vertical-sidewall grating lasers. Finishing the structures with optimized passivation layers, p-side gold heat-sinking, and facet coatings yields DFB lasers for efficient CW operation. The devices are then packaged in hermetically sealed TO housings with integrated thermoelectric coolers for operation at ambient temperatures.

Performance and applications

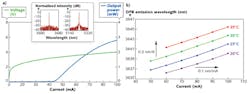

Typical performance characteristics of an interband-cascade DFB device include plots of optical output versus current (L-I) and voltage vs. current (V-I) for CW operation at a laser-chip temperature of 25°C (see Fig. 2a). Laser operation is achieved with low energy consumption with a threshold power below 0.15 W. Representative of DFB devices in the 3–6 μm range, singlemode spectra of two lasers have emission at 3.6 and 5.2 μm. Side-mode suppression ratios are higher than 30 dB (limited by the signal-to-noise ratio of the setup).By adjusting the thermoelectric cooler (TEC)-controlled chip temperature, the emission wavelength of the laser can be coarsely tuned to the desired value with a sensitivity of about 0.3 nm/K (see Fig. 2b). Single gas-absorption lines and their shapes may then be identified with very high precision and speed by current modulation of the DFB wavelength (approximately 0.1 nm/mA). Gas-absorption features within a range of around 10 nm can be scanned in this manner.

Applications for DFB ICLs include, for example, high-sensitivity sensing of NO and CO in combustion processes. Efficient process steering and pollutant reduction in the petrochemical industry is another high-impact application for hydrocarbon sensing. Another application is the detection of formaldehyde (CH2O), which has been used in the manufacturing of industrial products for nearly 150 years. Along with its use in consumer products, currently about half of the annual 21 million tons produced is used as an adhesive in wood-based panels.

Because formaldehyde has been classified as carcinogenic, real-time monitoring of its concentration for safety reasons not only in workplaces but also after the installation of the final products is of tremendous interest. While other measurement methods may suffer from low speed, low sensitivity, or interference with other hydrocarbons, TLAS detection of formaldehyde using a DFB ICL has proven to be much more advantageous.

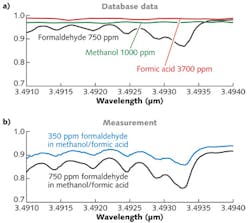

A DFB ICL tunable between 3488 and 3500 nm was used for the experiment.4 The laser light was collimated and passed through 15-cm-long gas absorption cells for direct-absorption spectroscopy (DAS) measurements; the cells contained gas mixtures of CH2O and formic acid/methanol as stabilizers. The laser current was varied from 48 to 115 mA to tune the DFB emission wavelength between 3491 and 3494 nm, allowing several characteristic absorption lines of formaldehyde within an atmospheric window to be addressed.

Calibrated transmission data from the Pacific Northwest National Laboratory database (http://nwir.pnl.gov) for a gas mixture based on 750 ppm of CH2O are shown in Fig 3a. The contributions of the stabilization gases are constant in the scanned wavelength region and must be subtracted from the measurement. Results from the DAS measurement for CH2O concentrations of 350 and 750 ppm using the DFB ICL are shown in Fig. 3b. The line positions and shapes could be reproduced very accurately in the absorption scan. The resolution of the sensor in this experiment was estimated to be about 1 ppm ⋅ m, which is suitable for monitoring the concentration of CH2O in workplaces.This experiment shows the great potential of DFB ICLs for use in TLAS. In addition to uses in industry, applications such as highly sensitive environmental spectroscopy of natural and artificial methane sources and medical breath analysis are possible with ICL technology. As a result of its low power consumption, battery-operated, handheld devices are now within reach and many more applications in the 3–6 μm wavelength range can be expected to be explored in the near future.

REFERENCES*

1. W. Zeller et al., Sensors, 10, 2492 (2010).

2. C. S. Kim et al., "Mid-IR Distributed-Feedback Interband Cascade Lasers," SPIE OPTO, 86311O (February 2013).

3. S. Höfling et al., "Low threshold interband cascade lasers," SPIE OPTO, 86311P (February 2013).

4. S. Lundqvist et al., Appl. Opt., 51, 25, 6009 (2012).

*For additional references, please visit http://bit.ly/16KBx4h.

Lars Nähle does technical process development and customer relations for DFB lasers >3 μm and Lars Hildebrandt is director of sales at nanoplus GmbH, Gerbrunn, Germany; e-mails: [email protected] and [email protected]; www.nanoplus.com. Martin Kamp is Chair for Technische Physik at the University of Würzburg, and Sven Höfling is head of the Optoelectronic Materials and Devices Group, Technische Physik, University of Würzburg; e-mails: [email protected] and [email protected].

![FIGURE 1. Absorbances of selected gas species with technological relevance in the range from 3–6 μm (a). Comparison of three different laser concepts for emission in the 'gap' region from 3–6 μm (b). Threshold power densities at room temperature are illustrated. Diode lasers are color-coded in black (results from University of Würzburg, Germany/nanoplus, Germany). Quantum-cascade lasers are red (results from Northwestern University, USA/Alpes Lasers SA, Switzerland). Interband-cascade lasers show significantly lower threshold power densities in the 3–6 μm range (green: results from Naval Research Laboratory, USA; blue: results from University of Würzburg, Germany). DFB ICLs with low power consumption for the entire range are feasible [compare DFB laser (green star) to BA results]. FIGURE 1. Absorbances of selected gas species with technological relevance in the range from 3–6 μm (a). Comparison of three different laser concepts for emission in the 'gap' region from 3–6 μm (b). Threshold power densities at room temperature are illustrated. Diode lasers are color-coded in black (results from University of Würzburg, Germany/nanoplus, Germany). Quantum-cascade lasers are red (results from Northwestern University, USA/Alpes Lasers SA, Switzerland). Interband-cascade lasers show significantly lower threshold power densities in the 3–6 μm range (green: results from Naval Research Laboratory, USA; blue: results from University of Würzburg, Germany). DFB ICLs with low power consumption for the entire range are feasible [compare DFB laser (green star) to BA results].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/1305lfw06f1.png?auto=format,compress&fit=fill&fill=blur&q=45?w=250&width=250)