3D photonic crystal creates high-quality warm-white LED

Standard white-light LEDs are made by layering a yellow-emitting cerium-doped yttrium-aluminum-garnet (YAG:Ce) phosphor over a blue-emitting gallium nitride (GaN)-based emitter; the combination of blue and broadband yellow approximates white light for many purposes. For indoor lighting, many people prefer a warm-white light; to achieve this, the proportion of light emitted by the YAG:Ce phosphor is increased. The result, however, is often light with a low color quality, sometimes even looking greenish. Correcting this problem usually means adding some expensive red-emitting phosphor to the mix. Even then, warm-light LEDs (w-WLEDs) have lower efficiency than cool-white LEDs (c-WLEDs).

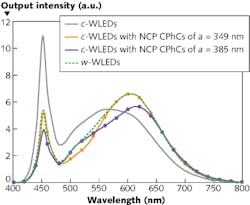

Researchers at Feng Chia University (Taichung, Taiwan) and Academia Sinica (Taipei, Taiwan) have come up with another approach for improving color quality: layering a 3D non-close-packed (NCP) colloidal photonic crystal (CPhC) with a unit-cell size (a) of 349 to 385 nm over the yellow phosphor. The stopbands in the CPhC improve both the color quality (quantified as the color-rendering index or CRI) and the closeness to a blackbody emission (quantified as the correlated color temperature, or CCT). And, because the researchers start by layering the CPhC on top of a more-efficient c-WLED, with the CPhC hardly affecting the efficiency of the resultant light output, the result is a more efficient w-WLED source. Contact Chun-Feng Lai at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.