Novalux (Sunnyvale, CA) chose the Optical Fiber Communication conference (OFC; Anaheim, CA) in March as the forum to reveal the long-awaited technical description of its "platform technology" for surface-emitting lasers. The company also introduced two continuous-wave (CW), room-temperature-operation, 980-nm erbium-doped-fiber-amplifier pump lasers: a single mode version at 200 mW and 360 mW, and a 750-mW multimode device. The company expected to make product samples of these devices, which are based on the Novalux extended-cavity surface-emitting laser (NECSEL) technology, available to select customers in April.

Prior to discussions at the Novalux commercial exhibit and a post-deadline paper delivered by chief technical officer Aram Mooradian, the company had discussed the developing technology only in general terms related to its potential applications in telecommunications, and possible advantages based on the vertical-cavity surface-emitting-laser (VCSEL) structural concept.

Mooradian's post-deadline OFC presentation, however, described the devices as electrically pumped gallium indium arsenide (GaInAs) surface-emitting semiconductor lasers with extended cavities to control both wavelength and optical mode. Mooradian said that the NECSEL design enabled the devices to perform more like solid-state lasers than traditional VCSELs. "This is not a waveguide device," he said. "It's a Gaussian free-mode laser."

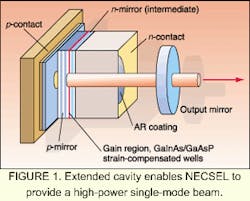

A key performance feature of the NECSEL is the ability to provide output powers on the order of a watt in single-mode operation and several watts multimode, with beam diameters on the order of hundreds of microns, an order-of-magnitude larger than traditional VCSEL designs, Mooradian said. He described the structure of the devices as a three-mirror coupled-cavity design (see Fig. 1). Epitaxial distributed-Bragg-reflector layers form the p- and n-mirrors on either side of the diode-laser active region. The output surface of the external cavity is formed by a curved external mirror, the design of which determines whether the device will operate multimode or in a single-fundamental TEM00 mode. The epitaxial n-mirror at the output side of the active region controls output wavelength.

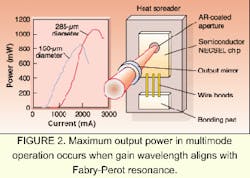

The thickness of the gallium arsenide substrate layer between the active region and the extended cavity ranges between 50 and 350 µm and has a relatively low doping level to minimize carrier-crowding effects along with electrical resistance. Operational efficiencies are on the same order as edge-emitting lasers, and the broad output aperture keeps optical intensity well below catastrophic optical-mirror-damage thresholds (see Fig. 2). The gain region in the devices consists of no more than three 8-mm-wide strain-compensated quantum wells for the low-power single-mode devices and is on the order of 4 to 10 quantum wells for the high-power multimode devices, Mooradian said.Coupling efficiencies of 90% and more than 85% have been achieved with single-mode and multimode optical fiber, respectively. Operating temperatures range from -20°C to +75°C, and the company is projecting a reliability figure of 1 million hours mean time before failure. While Novalux is focusing on telecommunications applications, the company also expects the device to have a significant impact in other areas such as displays, lighting, digital video, electronic theater, and medical instrumentation.

"The NECSEL is really a very flexible platform," Mooradian said.

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.