The most fundamental chemistry of life, such as the folding of protein molecules or photosynthetic reactions, takes place within picoseconds or femtoseconds (10-12 to 10-15 seconds). For many years, a high level of laser expertise was required in biology and chemistry labs to maintain the colliding-pulse modelocked dye lasers needed to study these ultrafast phenomena. Today turnkey versions of the fastest laser systems are expanding laboratory capabilities around the world, and are even finding their way into industrial applications.

Modelocking

Modelocking underlies all ultrafast laser operation. Consider a resonator containing one intense circulating pulse of light and a perfect shutter placed between the mirrors. The shutter opens long enough to pass only a pulse that arrives within a narrow time slot. This pulse will experience no loss if it circulates around the resonator with the same unchanging phase.

This configuration is equivalent to a continuous-wave (CW) laser supporting multiple longitudinal modes, all with the same phase, which are essentially superimposed into a single circulating pulse by the shutter. Each time the pulse reflects from the output mirror, a fraction of the energy leaks out with a repetition frequency determined by the round-trip time of the resonator (or the frequency spacing of the longitudinal modes), resulting in the characteristic modelocked output (see photo, this page).

Up until about ten years ago, dye lasers were used extensively to produce ultrafast pulses. Pulse durations of just a few femtoseconds or less were reported using colliding-pulse modelocking (CPM). CPM is one form of passive modelocking in that it makes use of a “saturable absorber”—a shutter with a period determined by the circulating pulse itself. This component becomes transparent to the laser wavelength when the intensity of the pulse exceeds a certain threshold (the upper absorber level becomes saturated).

A requirement of modelocking is that the time for the absorber to recover from saturation must be less than the interval between pulses. As a result, the leading and the trailing edges of a pulse experience loss, thereby shortening the pulse. If one thinks of the gain medium itself as a saturable absorber, it can be seen that modelocking may be a natural mode of operation for some types of CW lasers, which can be made to break into modelocked operation by tapping on the resonator.

There is no straightforward way to calculate the duration of a modelocked pulse, but it will depend upon the number of longitudinal modes available to be superimposed. The number of modes in turn depends upon the bandwidth of the laser gain. As a rule, narrower modelocked pulses will result when a greater number of modes are supported by a broader transition (as in a dye laser). The broadest laser medium, Ti:sapphire, was a natural candidate to produce ultrafast pulses.

The magic is gone

The commercial introduction of modelocked Ti:sapphire lasers in 1990 by Spectra-Physics (Mountain View, CA) began a revolution in the marketplace. Ti:sapphire is the most successful of a class known as vibronic solid-state lasers. Unlike Nd:YAG, for example, the energy levels in vibronic lasers are spread into bands by the interaction of the laser dopant with the host crystal. Laser transition takes place between an essentially continuous spectrum of upper and lower levels, resulting in a tuning range from less than 700 nm to more than 1100 nm.

The broad gain spectrum of Ti:sapphire makes it a great candidate for modelocking. However, passive modelocking of Ti:sapphire was thought to be impossible due to an absence of saturable absorbers with a fast enough recovery time. But in 1990, researchers at the University of St. Andrews (Fife, Scotland) serendipitously discovered that their laser was in modelocked operation. So surprising was this result that it was referred to as “magic modelocking.” In less than a year the magic was gone, as a team from the Center for Ultrafast Optical Science at the University of Michigan (Ann Arbor) explained passive modelocking of Ti:sapphire as a result of Kerr-lensing.

This effect is a nonlinear phenomenon in which an intense beam changes a medium's index of refraction and self-focuses the beam, resulting in still greater intensity and further focusing. In a Ti:sapphire laser, Kerr-lensing preferentially selects a noise spike that overlaps the pump beam to be amplified into a modelocked pulse.

At the same time, another nonlinear effect called self-phase modulation produces additional frequency components in the cavity at multiples of the round-trip frequency. More complexities are involved, but the final result is the same as adding more in-phase longitudinal modes to the frequency content of the circulating pulse: the pulse narrows.

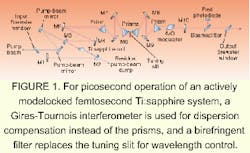

Kerr-lens modelocking forms the basis of several commercial ultrafast systems, but not all of them. In active modelocking, an acousto-optic modulator at a set frequency forces a laser into modelock. It is more complex and expensive than passive modelocking, but probably more reliable for operation of a tunable system. (Tapping on a resonator can also put an end to modelocked operation.) According to Richard Boggy, engineering manager of the Ultrafast Products Group at Spectra-Physics, “An intracavity A/O modulator stabilizes modelocked performance, especially in the picosecond pulse regime” (see Fig. 1).Dispersion, bad and good

To understand the most significant design problem in ultrafast systems, it is important to realize that the usual monochromatic property of laser output doesn't apply to ultrafast pulses. The frequency (or wavelength) content of a pulse is inversely proportional to the pulse width; for example, a 10-fs pulse centered around 1 µm is about 100 nm wide. It is crucial to modelocking that all frequency components experience the same round-trip cavity time, but even modest dispersion will lengthen or terminate the pulsed output.

Dispersion in the cavity is compensated for by adding optical elements—typically pairs of prisms or gratings, a length of optical fiber or, with increasing popularity, specially coated mirrors—that slow the passage of wavelength components of the pulse as needed to keep them in phase. The degree of dispersion compensation is adjustable to allow for different operating conditions.

Any discussion of ultrafast systems would be lacking if it did not discuss their potential for extremely high peak power. Using a technique called chirped pulse amplification (CPA), pioneered by Strickland and Mourou in 1985 while at the University of Rochester (New York), for the briefest of times a pulse can be boosted to the most intense radiation source on Earth. As a first step, an external device such as a Pockels cell selects pulses from the modelocked laser at perhaps a 1-kHz rate and directs them into the external amplifier. Chirped pulse amplification then turns the problem of the dispersion of the ultrafast pulse into a benefit.

There are many CPA configurations, but typically pulses are sent through a dispersive optical element that slows the passage of the high-frequency components and lengthens the pulses, possibly into the nanosecond range. The pulse energy can be amplified in a Ti:sapphire rod without risking damage to the system components or distortion of the pulse by nonlinear optical effects. Since pulse energies are typically less than a Joule, high beam-quality is easier to maintain. The energetic pulses are now sent through optical elements with "negative dispersion" that retard the low-frequency components and compress the pulses back to the ultrafast regime.

Chirped-pulse amplification techniques achieved peak powers greater than a Petawatt (1015 W) in the laboratory in the mid-1990s. The extreme electric fields at these levels may enable a new range of experiments in basic physics, both by direct application or indirectly by powering new particle accelerators. Feasibility studies are under way to explore the practicality of using ultrafast lasers to shrink the size of existing accelerators by as much a thousandfold (see Laser Focus World, May 1999, p. 155).

Simpler still

Not all applications of ultrafast pulses require cutting-edge performance, and while simpler and more reliable than dye laser systems, ultrafast Ti:sapphire lasers are still complex and expensive devices. Part of the complexity and expense is the result of their blue-green pump band, requiring a laser such as a frequency doubled Nd:YLF as the pump source. Some available systems use solid-state materials that allow direct pumping of the laser crystal by diode arrays.

Interest centers on chromium in various crystals such as LiSrAlF6 (Cr3+:LiSAF), which has a pump band centered around 630 nm. Past efforts to use Cr3+:LiSAF crystals have been frustrated by material problems—they are inferior to Ti:sapphire in optical and thermal properties (and in availability). In addition, diode lasers of sufficient power around this wavelength have had reliability issues.

Nevertheless, such lasers are commercially available. Recent research has shown that reliable femtosecond output from Cr3++:LiSAF can be achieved using pump powers as low as tens of milliwatts, much lower than previously thought possible. The potential benefits of direct pumping of chromium will undoubtedly spur research into various hosts.

Like ultrafast chromium lasers, rare-earth-doped fiber lasers sacrifice some performance for simplicity. One commercially available erbium-doped fiber system, for example, offers pulses as short as 100 fs at 1560 nm, with tens of milliwatts average power on a footprint of about 10 × 20 cm. Such diode-pumped systems may even be battery-operated. These lasers lack tunability—a major drawback—but they are compact and inexpensive compared to Ti:sapphire-based systems, and many applications can make use of their near-infrared output.

Let it bleed

Ultrafast pulses allow efficient nonlinear conversion to other wavelengths using frequency doubling or tripling and optical parametric oscillators (OPOs), often combined in series. This output spanning from the ultraviolet well into the infrared enables a wide range of laboratory applications. For instance, two OPOs pumped by the same ultrafast system can be synchronized and used to first excite and then examine the Raman spectrum of a molecule involved in human vision.

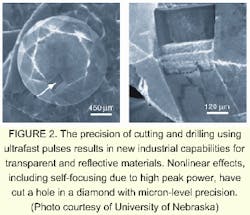

The latest uses of ultrafast pulses are in areas where other lasers traditionally have been used to ablate material, such as surgery and material processing. The biggest advantage of ultrafast pulses in these applications is their precision in limiting material damage to the target area (see Fig. 2). The pulses ionize the target faster than thermal energy can diffuse to surrounding material. This limits collateral damage and allows repeatable micron-sized cuts.In the emerging surgical application, this means little if any burning and tearing to neighboring tissue. Unlike other laser surgery, which typically cauterizes an incision, cuts made with an ultrafast laser will bleed. The pulsed beam also can be focused beneath the skin, allowing for some types of incisionless surgery without damage to intervening tissue. In addition, cuts on the dimensions of microns may result in new capabilities to surgically repair nerve damage.

Next month the series reviews developments in organic LEDs.

About the Author

Stephen J. Matthews

Contributing Editor

Stephen J. Matthews was a Contributing Editor for Laser Focus World.