In practical terms, the phrase “tunable solid-state laser” is almost synonymous with the Ti:sapphire laser. The introduction of the continuous-wave (cw) Ti:sapphire laser in 1988 began a revolution in the scientific laser marketplace that has expanded beyond the laboratory. Laser systems that in years past would have been found only in research environments are now being produced in turnkey versions for industrial applications. (Ed. note: tunable fiber lasers and tunable semiconductor lasers will be discussed in future articles in this series.)

This evolution has been achieved in a series of distinct milestones, most notably the invention of the cw Ti:sapphire laser, the development of modelocked systems, the use of diode-pumped solid-state lasers (DPSSLs) as pump sources, and recent improvements in frequency conversion techniques that have dramatically expanded the tunable output spectrum.

Crystal by design

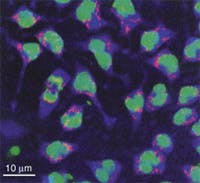

Prior to Ti:sapphire, the dye laser was by far the pre-eminent tunable system, and it was the enabling technology in the emerging study of ultrafast phenomenon. By changing dyes, dye lasers completely cover the visible and near-IR spectrum. While Ti:sapphire has by far the broadest tuning range of any single laser medium, its output, centered at 800 nm, does not extend to most visible wavelengths (see photo, this page). However the superiority of the new laser was so clear-cut that many chemists and biologists changed the phenomena they were studying to take advantage of the new technology.

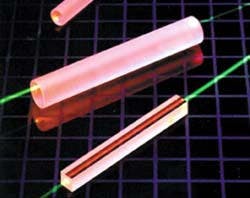

Ti:sapphire offers continuous output from 680 to 1100 nm, with narrow linewidth, low noise, and good beam quality available at the wavelength selected. Ti:sapphire requires another laser as its pump source. With modern DPSSL sources of 5 W and above, output power is well above 1 W in the center of the spectrum (although power drops sharply at the wings).

Peter Moulton is widely credited with inventing the Ti:sapphire laser while working for Lawrence Livermore National Laboratory (CA) in the 1980s. Moulton theorized that the properties of triply ionized titanium in a crystal would have essentially no excited-state absorption, which is deleterious to laser pumping or emission. Moreover the interaction of the titanium with the thermal vibration of the host lattice would likely produce a broad and tunable output, an example of a “vibronic” transition. As luck would have it, a titanium-doped sample of Al2O3 (in its crystalline form, sapphire)—Ti:sapphire—was already on hand at the lab.

Before long, Ti:sapphire lasers were in full production, most notably at Schwartz Electro-Optics (now Q-Peak; Bedford, MA) and Spectra-Physics (Mountain View, CA). The Spectra-Physics system began as a laboratory tool used to study the absorption spectra of Nd:YAG in an effort to develop a DPSSL—a study that would later return dividends for Ti:sapphire itself. But at the time, water-cooled argon-ion lasers were available and well suited as pump sources. Attention quickly turned to modelocking Ti:sapphire.

Magic modelocking and DPSSL pumping

As with dye lasers, the broad tuning range of Ti:sapphire indicated the possibility of producing ultrafast pulses. With the right combination of optical elements, it was found that Ti:sapphire will self-modelock, thanks to a nonlinear phenomenon in the crystal that has come to be known as Kerr-lens modelocking. At the time of its serendipitous discovery at St. Andrews University (Scotland) in 1988, however, the phenomenon and its underlying theory were mysterious enough to be called "magic modelocking."

The Mira system from Coherent Lasers (Santa Clara, CA) was the first femtosecond Ti:sapphire laser to market, demonstrating that the remarkable properties of ultrafast pulses that had been the exclusive province of dye lasers could be found in a system of much greater convenience. Since then, the ultrafast portion of the market has grown to dominate Ti:sapphire sales.

The next major step in the Ti:sapphire story was the replacement of argon-ion pump lasers by frequency-doubled DPSSLs, such as Nd:YAG and more recently Nd:YVO4. Although more expensive, the convenience, reliability and compact size of these pump sources spurred another surge in Ti:sapphire popularity. It took several years of development before the frequency-doubled output of DPSSLs reached sufficient power levels (5 W or higher) to be acceptable pump lasers. The introduction of the Millenia from Spectra-Physics in 1996 set the early standard for these all-solid-state systems.

Physics and design

Ti:sapphire is produced by mixing a small amount of Ti2O3 into a melt of Al2O3. A boule is drawn from this melt in which a small percentage of the Al3+ in the sapphire is replaced by Ti3+. The Ti3+ electron has only one d electron and therefore only two possible ground- state energy levels. These levels are spread into a pair of energy bands by the vibronic interaction.

As Moulton realized, the energy levels of Ti3+ are unique among transition metals in that there is no d state above the upper laser level. This virtually eliminates excited-state absorption of the laser and pump wavelengths. The vibronic bands effectively act as a classical four-level laser transition. Transitions between these bands are responsible for the uniquely broad range of emission.

Absorption occurs over wavelengths from 400 nm to beyond 600 nm. Although fluorescence extends down to 600 nm, lasing occurs only at wavelengths longer than 670 nm because absorption overlaps the short wavelength end of the fluorescence (see Fig. 1). The presence of Ti4+, along with other details of the crystalline structure (which depend on growth techniques and doping concentration) can negatively affect performance as a laser crystal.An early and important concern was represented by the so-called Figure of Merit. For Ti:sapphire, this is the ratio of the value for the absorption of pump light at 490 nm divided by the absorption in the crystal of the peak emission wavelength at 800 nm. For early samples this ratio was perhaps 50 or so, whereas today a figure greater than 100 is considered acceptable. To achieve these values it was found that doping levels had to be kept quite low compared to other solid-state materials—much lower, for example, than the levels of neodymium in YAG.

This low level of titanium doping along with the short upper-state lifetime of the material (3.2 µs) guides the laser design—most significantly, in the need for a high-brightness pump source. A typical pump laser needs to have 5 to 10 W of TEM00 (M2 < 1.1) focused to a spot size around 50 µm. Under these conditions, perhaps 80% or more of the pump power is absorbed by the Ti:sapphire crystal.

OPOs and their cousins

Modelocking greatly aids nonlinear frequency conversion techniques, such as frequency doubling, because the efficiency of nonlinear conversion rises steeply with peak input power. Frequency doubling Ti:sapphire produces tunable output from the near UV into the green, from about 350 to 550 nm (see Fig. 2). More recently, new crystals have enabled a variety of nonlinear techniques that produce, from an integrated multistage system, tunable femtosecond pulses that span from 300 nm to 10 µm.Central to such a system is the optical parametric oscillator (OPO). An OPO divides the input light into two longer-wavelength tunable outputs, one of which is selected to extend the Ti:sapphire range from, say, 1.1 µm out to 2.6 µm. This infrared output can either be used directly in an application or fed into another nonlinear crystal (such as another OPO) for further conversion to shorter or longer wavelengths. If the OPO includes an amplification stage, it might be termed an OPA, or optical parametric amplifier.

New tunable UV lasers

A great deal of simplicity could be achieved in producing tunable ultraviolet (UV) light by using a vibronic crystal that lases in the UV. In recent years, research has been directed toward the fluoride-containing colquiriite crystals, such as LiCAF (LiCaAlF6), which is a naturally occurring mineral reportedly first found in a Bolivian tin mine.

Doping the colquiriites with cerium (Ce) produces tunable laser crystals with output in the near UV, roughly from 280 to 315 nm. Significantly, LiCAF and its cousin, LiSAF (LiSrAlF6), have absorption bands at 266 nm, the frequency-quadrupled wavelength of Nd:YAG and Nd:YVO4. Although frequency quadrupling is by no means routine, DPSSLs are available at this wavelength with outputs exceeding 1 W, making UV systems that much more compact, reliable and easy to tune. Such systems are currently in use for remote atmospheric sensing, combustion diagnostics, and short-pulse generation for a wide variety of research.

These materials do have several drawbacks that make them difficult to work with, including thermal limitations that can cause the crystals to break at higher pump powers. Efficiency can be limited by thermal population of the laser states, and other issues may limit these systems to low-power applications. However other colquiriites may prove superior. The metallic component in the colquiriite can be one of several elements, and LiGAF (which contains gallium), for example, may be a mechanically superior host. The laser action in all such materials is the 5d1 = > 4f1 transition of the Ce3+ ion.

Tunable DPSSLs

Although pumping by DPSSLs has been a boon to Ti:sapphire technology, systems would be simpler and cost savings would result if Ti:sapphire could be pumped directly by laser diodes. But when blue or green diode arrays eventually become available, it is unlikely that their beams will be bright enough to pump Ti:sapphire, even if their output has sufficient power. The relatively low excited-state cross section of Ti:sapphire requires a much tighter focus of the pump beam than is commonly used, say for pumping DPSSLs.

This restriction does not apply to several chromium-doped vibronic crystals, however, most notably alexandrite (Cr3+:BeAl2O4). Flashlamp-pumped alexandrite lasers have been around for years but have enjoyed limited application because of thermal problems and self-absorption of the output wavelengths. This material system received new interest following the availability of high-power arrays of indium gallium aluminum phospide at 670 nm, within the main pump band of alexandrite.

Alexandrite has some properties that make it an attractive laser material, including a respectable upper state lifetime of 260 µs (good for Q-switching). Diode-pumped alexandrite lasers are commercially available with a tuning range of 720 to over 800 nm and powers in the tens of milliwatts. Allied Signal Corp. (Morristown, NJ) reportedly has invested more than $100 million in the development of alexandrite laser systems.

Other chromium-doped vibronic materials have broader tuning ranges in the near IR and have received considerable research interest as possible diode-pumped tunable sources. These include forsterite at 1200 to 1350 nm, and the colquiriites (here doped with chromium rather than cerium) between about 750 and 900 nm. However InGaAlP diode arrays still require considerable improvement before their reliability matches that of the AlGaAs arrays used to pump DPSSLs.

Next month the series reviews development and advances of fiber lasers.

REFERENCE

- Adapted from P. F. Moulton, J. Opt. Soc. of America B, 3(1) (1986).

About the Author

Stephen J. Matthews

Contributing Editor

Stephen J. Matthews was a Contributing Editor for Laser Focus World.

![FIGURE 1. The energy level diagram of Ti:sapphire, together with the absorption and emission spectra. Interaction of the titanium electron with the Al2O3 lattice produces wide spreading of the energy levels and results in broad tuning [1]. FIGURE 1. The energy level diagram of Ti:sapphire, together with the absorption and emission spectra. Interaction of the titanium electron with the Al2O3 lattice produces wide spreading of the energy levels and results in broad tuning [1].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/th_80289.png?auto=format,compress&fit=max&q=45?w=250&width=250)