Quantum cascade lasers shape up for trace-gas sensing

CLAIRE GMACHL, FEDERICO CAPASSO, RAFFAELE COLOMBELLI, ROBERTO PAIELLA, DEBORAH L. SIVCO, and ALFRED Y. CHO

Quantum cascade (QC) lasers are semiconductor injection lasers based on intersubband transitions in a multiple quantum-well heterostructure. They are designed by means of band-structure engineering and grown by molecular beam epitaxy.1 Since their invention only seven years ago at Bell Labs, they have reached an impressive level of maturity, demonstrated both by their recent transition into the marketplace and by the large number of research groups conducting related research worldwide (see "Quantum cascade lasers find use in trace-gas sensing applications").

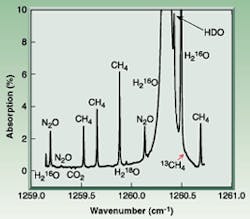

Quantum cascade lasers grown in the indium gallium arsenide/aluminum indium arsenide material system have, until now, been fabricated for emission wavelengths as short as 3.5 µm and, recently, as long as 24 µm.2 The wavelength coverage of these lasers extends nearly continuously through the mid-infrared and reaches into the far-infrared (see Fig. 1). This large range means that the primary application of these lasers is trace-gas sensing. Many trace gases have telltale absorption features in this wavelength range that result from vibrational and mixed rotational-vibrational transitions. To qualify as a superior source for such sensing applications, a laser needs to fulfill several requirements. It must be single mode and continuously tunable, must display a narrow linewidth (relative to the width of the trace gas absorption exotic lasers in question), and—for reasons of economics—must operate at high temperature, with good long-term stability and reliability. Quantum cascade lasers excel under all those requirements.Continuously tunable single-mode operation

Single-mode operation is achieved through integration of a Bragg grating into the laser waveguide, resulting in a distributed feedback (DFB) laser. The latest generation of QC-DFB lasers is based on a so-called "top-grating" approach that takes particular advantage of the characteristics of the mid-infrared waveguide (see Fig. 2).3 For wavelengths between 3.5 and approximately 15 µm, the latter is commonly a dielectric waveguide built from low-doped semiconductor layers that have the appropriate refractive-index contrasts.If such a waveguide—with tight confinement to condense long-wavelength light in a reasonably thin layer stack—is directly overlaid with metal (for example, top-contact metallization), then light is guided not only by the dielectric contrast of the semiconductor layers but also by the surface plasmon mode. The latter propagates at the metal-semiconductor interface. A pure surface plasmon waveguide is inherently more lossy than a dielectric waveguide; however, it can be designed with additional refractive-index contrast to display a much tighter optical confinement than the latter.

Combined with reduced penetration depth into metal at longer wavelengths, a surface plasmon waveguide is in fact favorable for longer wavelengths—those longer than approximately 15 µm. At the shorter wavelengths, however, the coupling to the surface plasmon waveguide can be suppressed by a topmost semiconductor waveguide layer so highly doped that it displays the anomalous dispersion of the plasma edge and a concomitant strongly reduced refractive index of less than or equal to 1.

The QC-DFB top grating is etched into this topmost layer such that the grating grooves fully penetrate through the layer while the grating ridges remain unetched. If this grating structure is overlaid with metal, a periodic coupling to the surface plasmon mode results for the guided mode, with strong periodic modulations. Single-mode operation results then from Bragg scattering off this grating, and continuous tunability is achieved through the temperature dependence of the above mentioned waveguide parameters. The temperature can either be varied by a temperature change of the heat sink and mounted device or—more rapidly—by an added direct current through the device and dissipative heating. Characteristic total tuning ranges per current sweep are around 0.3% to 0.5% of the emission wavelength, which permits the scanning of several (often up to 10) isolated absorption features of a trace gas.

In addition to continuous tunability, the narrowness or monochromaticity of the laser emission is a crucial factor. Coworkers at Pacific Northwest National Labs (Richland, WA) and JILA/NIST (Boulder, CO) have used known gas absorption features or high-finesse Fabry-Perot cavities to determine the linewidth of several QC-DFB lasers as being a few 100 kHz when free-running and a few kHz when frequency-stabilized.4 Such narrow lines are clearly atypical of semiconductor lasers and illustrate the uniqueness of the intersubband nature of light generation.

The remaining requirements of device reliability and long-term stability are fulfilled through the choice of well-tested and reliable materials, such as indium phosphide and gallium arsenide-based heterostructures. Finally, the operating temperature of QC lasers has long reached above room temperature for pulsed operation and encouraging progress has been made recently for continuous-wave operation as well.5

Far-infrared QC lasers

It is a key strength of the QC concept that the emission or peak gain wavelength can be chosen freely within a very wide range by design of layer thicknesses. A firm boundary only exists at the short wavelength side given by the band offset between the quantum wells and barriers of the respective materials. For ever-longer wavelengths, however, the question remains whether enough gain can be generated to overcome the increasingly larger waveguide loss. In general, free carrier losses even in the very low-doped semiconductor layers are noticeable. As a solution, a surface-plasmon waveguide maximizes overlap of the guided mode with active material and minimizes overlap with passive and lossy waveguide layers. This approach was taken in the most recent realization of the first far-infrared QC lasers at 21.5- and 24-µm wavelengths.2 The active material was composed of so-called "chirped" superlattice active regions interleaved with injector regions, making optimal use of the cascading scheme by stacking up to 65 active regions and thus multiplying the modal net gain accordingly. The lasers operated in pulsed mode up to approximately 150 K heat-sink temperature and with peak output power levels of a few milliwatts. Threshold current density values of greater than 4 kA/cm2 were obtained.

Similar to their mid-infrared counterparts, the long-wavelength QC lasers are expected to be used in trace-gas sensing—in particular of heavy molecules—and potentially as local oscillators for spectroscopy applictions in astrophysics.

Short-pulse operation of QC lasers

Most physical systems can be described on two time scales corresponding to their steady state and dynamic behaviors. The invention of an ultrafast (picosecond to femtosecond) light source in a certain spectral range typically opens up an entire new range of phenomena related to that time scale and frequency range. One prime example has been the Ti:sapphire laser operating at around 1 µm. It is therefore highly desirable to develop comparable short-pulse and high-power sources that operate in the mid-infrared wavelength range and beyond.

The electron dynamics at the heart of QC lasers occur on a picosecond time scale, sped up by optical phonon scattering between electron subbands. The QC laser therefore lends itself to ultrafast modulation and short-pulse emission. Recent work has demonstrated gain switching with pulse widths of approximately 50 ps, and active and passive modelocking leading to 3- to 5-ps short pulses with approximately 12-GHz repetition rate and an average power output of a few tens of milliwatts at both investigated wavelengths of 5 and 8 µm.7 Such ultrafast QC lasers should in the near future become sources for time-resolved mid-infrared spectroscopy.

ACKNOWLEDGMENT

The authors would like to acknowledge the help of M. I. Blakey, A. L. Hutchinson, A. M. Sergent, and S. N. G. Chu with device processing and characterization, and they thank H. C. Liu of NRC, Ottawa, Canada, for the loan of high-speed QWIP detectors. This work was partly supported by DARPA/US ARO under contract number DAAD19-00-C-0096.

REFERENCES

- F. Capasso et al. IEEE J. Select. Topics Quant. Elect. 6, 931 (November/December 2001) and references therein.

- R. Colombelli et al., Appl. Phys. Lett. 78, 2620 (2001).

- R. Köhler et al. Appl. Phys. Lett. 76, 1092 (2000).

- R. M. Williams et al., Opt. Lett. 24, 1844 (1999) and private communications.

- D. Hofstetter et al., Appl. Phys. Lett. 78, 396 (2001) and Appl. Phys. Lett. 78, 1964 (2001).

- C. Gmachl et al., Reports on Progress in Physics, in preparation.

- R. Paiella et al., Science 290, 1739 (2000) and references therein.

Claire Gmachl, Federico Capasso, Raffaele Colombelli, Deborah L. Sivco, and Alfred Y. Cho are researchers at Bell Laboratories, Lucent Technologies, 600 Mountain Ave., Murray Hill, NJ 07974; e-mail: [email protected]. Roberto Paiella was with Bell Laboratories and is now a researcher at Agere Systems, Murray Hill, NJ.