Vertical-cavity surface-emitting lasers (VCSELs) show conically shaped emission that favors coupling of the radiation into an optical fiber. In addition, they excel in longitudinal single-mode emission and low power consumption. The development of VCSELs has been driven by the devices' advantages for telecommunications. Gallium arsenide (GaAs)-based VCSELs emitting at around 850 nm are used in local-area optical networks. Because they can be produced more cost-efficiently than edge-emitting lasers, GaAs-based VCSELs already have acquired a considerable share of the near-infrared emitter market.

For long-haul telecommunications, the second and third telecommunication windows at 1.3 and 1.55 µm, respectively, are more important because of the considerably lower attenuation of optical fibers at these wavelengths. Consequently, great efforts have been focused on making VCSELs operate in those spectral regions. Recently, considerable progress was achieved. For the 1.3-µm band, several approaches based on GaAs were used to narrow the material's band gap to result in a 1.3-µm transition wavelength. In one approach, nitrogen (N) was added to indium gallium arsenide (InGaAs). With InGaAsN quantum-well VCSELs, high bit rates up to 10 Gbit/s were demonstrated.1, 2

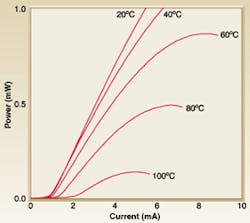

For 1.55-µm emission, a research group at Walter Schottky Institute (Munich, Germany) recently fabricated VCSELs based on buried-tunnel-junction (BTJ) technology that produced up to 2-mW optical output at room temperature.3 In addition, this group increased the output power of 20 x 20-µm devices to 7 mW at room temperature.4 Laser operation was possible up to 110°C (see figure). The BTJ-VCSEL contains five 8-nm-thick compressively strained indium gallium aluminum arsenide quantum wells and is based on indium phosphide. The improvement in output power was achieved by lowering the series resistance to 11 W so that operation voltage at maximum output power amounted to less than 1.4 V. The low series resistance was provided by a redesign of the front mirror layers (99.4% reflectivity) by modulation doping.

The threshold voltage for the onset of lasing of VCSELs with different BTJ apertures (ranging from 2 x 3 µm to 20 x 20 µm) never exceeded 0.9 V at room temperature. The 5 x 6-µm VCSEL exhibits about 1-mA threshold current, more than 1.5-mW optical output, and a 30% slope efficiency at 20°C. A continuous-wave output of 0.5 mW was measured at 80°C. The authors claim that with these characteristics their device outperforms any other 1.55-µm VCSEL with data so far published. For application in a telecommunications network, sufficient optical output at elevated temperatures is essential.

The researchers are currently investigating the high-frequency response of BTJ-VCSELs. They have produced devices with an acceptable eye diagram at 2.5 Gbit/s and foresee further increase of modulation bandwidth up to 10 Gbit/s and beyond.5

REFERENCES

- G. Steinle et al, Elect. Lett 37(10) 632 (May 2001).

- R. L. Naone et al., Photonics West, CPD13-1 (Jan. 2001 / San Jose).

- M. C. Amann, 2001 Int. Conf. on Indium Phosphide and Related Materials (13th IRPM, May 14-18, 2001, Nara, Japan)

- R. Shau, M. et al., accepted by Electr. Lett.

- M. Ortsiefer et al., ECOC 2001, Post Deadline Paper.

About the Author

Uwe Brinkmann

Contributing Editor, Germany

Uwe Brinkmann was Contributing Editor, Germany, for Laser Focus World.