Within the past few years, diode-pumped solid-state lasers (DPSSLs, pronounced “dipsels”) have emerged from the laboratory into everyday use in industrial and medical applications. This is the result of several developments—more efficient use of frequency-conversion techniques, hands-off reliability, user-friendly computer interfaces—but as has been the case throughout the history of this technology, the most important factors are the increase in power and the reduction in price of the laser-diode pump sources.

Higher-power laser-diode arrays translate directly into higher-power DPSSLs, which are now available at kilowatt power outputs and are finding application in industrial markets formerly dominated by other lasers (see photo at top of this page). Forty-watt laser-diode bars of aluminum gallium arsenide 1 cm in width are standard, and prices are projected to fall to a few dollars per watt in the next few years. Derating the laser diodes (turning down their output power) leads to increased lifetime and the hands-off reliability of new applications.

A cool start

The very first laser was a solid-state laser; that is, a crystal doped with a metallic or metal-like element that emits laser light and is optically pumped. Because they obviously predated the development of the semiconductor or laser diode, the term "solid-state laser" came to refer to such lasers and not to semiconductor lasers. Optical pumping was by means of a flash lamp, and similar designs are still very much in use.

Soon after the laser diode was invented it was realized that if its wavelength matched the absorption spectrum of a laser crystal, a much more efficient solid-state laser would result. As early as 1964, Keyes and Quist at MIT's Lexington Labs (MA) used GaAs laser diodes to pump uranium in a calcium fluoride host to produce a 2.6-µm output. The fact that the MIT experiment was cooled with liquid helium underscored the major difficulty with the technology—the reliability limitations of the laser diodes.

By the end of the 1960s, researchers were pumping the absorption band of Nd:YAG near 800 nm with laser diodes, the preeminent DPSSL combination in use to this day. These devices still needed cryogenic cooling, however, which confined the DPSSLs to the laboratory. When reliable laser diodes of much higher power became available in the mid-1980s, it rekindled intensive development efforts.

Some benefits of this technology were obvious for two decades before they were realized. Lamp sources are high-voltage and high-temperature devices that require water cooling and replacement every few hundred hours. In contrast, the efficiency of the laser diodes greatly increases DPSSL wall-plug efficiency to the point that small air-cooled devices may be battery powered. Device lifetimes typically are measured in thousands of hours. Compared to lamp pumping, the lower thermal load of the DPSSL configuration enhances some solid-state laser advantages—high beam quality and low divergence, stable output, and broad control of parameters for pulsed output.

Neodymium is by far the most common laser element used in DPSSLs. As a dopant in a host crystal lattice (a 1% concentration is common), neodymium has an absorption band in the near-infrared that is a serendipitous match to the output of high-power laser-diode arrays (see Fig. 1). The preferred laser transition is at 1064 nm. Fast relaxation to the ground state from the lower laser state is one of the factors that results in high gain of neodymium-doped materials.Because the host essentially "ionizes" the neodymium, it follows that the transparent host material has a significant effect on the laser output. Glass is a common neodymium host for lamp-pumped lasers, but Nd:glass is a poor conductor of heat, and the availability of large glass rods is not a particular benefit for DPSSLs. In general, crystals are much better heat conductors than glass, an important consideration because thermal issues are a major concern for diode-pumped systems.

Crystal clear choice

Over the years, many crystals have been proposed or demonstrated in the lab, but the choice of a host is as much a practical matter as it is a theoretical one. Availability and cost, size, and quality are as important to a DPSSL manufacturer as the laser parameters of the host material. Developing a new laser crystal that is profitable to manufacture is time-consuming and expensive, and not undertaken unless there is significant economic potential.

The most common host crystals today are YAG (yttrium aluminum garnet, called "yag"), YLF (yttrium lithium fluoride, called “yilf”) and YVO4 (yttrium vanadate, called simply “vanadate”). The choice of a crystal depends upon the details of its intended applications. A scientific user often uses a DPSSL as a pump source for a tunable laser, and wants high-power continuous-wave or modelocked output. The industrial customer typically needs a Q-switched laser, and here the energy, duration, and repetition rate of the pulses determine the laser design.

About a decade ago, the unique properties of Nd:YLF combined with improvements in the quality of available crystals brought it to commercial prominence. The rate at which the index of refraction of this crystal changes with temperature is exceptionally low, reducing the problems of thermal lensing at higher pump and DPSSL powers. In addition, Nd:YLF has a long upper-state lifetime, allowing Q-switched pulses of high energy. This material is often found in Q-switched DPSSLs with repetition rates below 5 kHz, such as might be used to pump an amplifier. The pulses tend to be somewhat long for some applications.

Like Nd:YLF, the newer crystal Nd:YVO4 is birefringent. Rods made from these crystals have a simpler geometry because they do not need to be cut at Brewster's angle to produce polarized output. Birefringence results in a laser transition having two separate emission lines. The 1053-nm line is preferred over the 1047-nm line for Nd:YLF because it makes best use of the material's low thermal lensing. The 1064-nm line of Nd:YVO4 is commonly chosen as a match to the familiar output of Nd:YAG.

Yttrium vanadate has been growing in popularity because of its high gain and low threshold, which result from the excellent fit of the neodymium dopant in the crystal lattice. The low threshold makes this material a good choice for low-power devices such as hand-held pointers. High-end systems are high-average-power, short-pulse (typically 10 ns) Q-switched lasers with repetition rates 10 kHz or higher. The comparatively short upper-state lifetime, less than half that of Nd:YAG, limits the energy that can be stored in the laser transition, so although Nd:YVO4 can produce high peak powers, the pulses have lower energy than competing crystals.

In use for almost four decades, Nd:YAG has been and is still the most commonly found DPSSL crystal. It is relatively inexpensive, it is readily available in large rods of excellent quality, and its laser parameters are a good compromise between the strengths and weaknesses of its competition. All types of DPSSL systems—frequency-doubled continuous wave, high-energy Q-switched, and so forth—are still produced using Nd:YAG rods.

Putting it all together

The rods themselves are typically small cylinders with dimensions measured in millimeters or centimeters. There are two basic geometries for delivering the laser-diode power to the rod—end pumped and side pumped, with variations upon each. End pumping produces a higher-quality DPSSL beam and is the preferred design, except when considerations of high power are predominant in which case side pumping is superior. End pumping can be either close coupled (the laser diodes are adjacent to the rod) or fiber coupled.

The close-coupled design is simpler and more efficient because a greater percentage of the laser-diode output is transmitted to the rod, while the advantages of fiber coupling are that it moves the heat produced by the laser-diode arrays away from the DPSSL cavity and it is simpler to replace the arrays in the field (the arrays are placed in a separate power supply). Moreover, the fibers themselves serve to shape the pump beam to match the DPSSL mode.

Proper mode matching is one of the keys to optimizing DPSSL performance. The shape of the pump beam is formed into the same shape as the output-beam mode inside the laser crystal. End pumping allows the laser-diode beam to be focused into a volume in the crystal that best matches the shape of the commonly specified TEM00 mode. In general, the mode radius is chosen to be as small as possible to minimize the threshold of DPSSL lasing.

Coupling higher-power laser-diode arrays, which have wide, asymmetric beams, into the rod while still maintaining a low lasing threshold and good DPSSL beam quality is a challenge. The choice of laser crystal is critical here, as good values for optical parameters such as gain must be weighed against material parameters such as heat dissipation.

The design of the DPSSL cavity can become quite complicated if, as is often done, its wavelength is frequency doubled using a nonlinear intracavity crystal such as lithium borate or potassium tilenyl phosphate. In this case, care must be taken to avoid unacceptably large amplitude fluctuations resulting from mode competition in the doubled output (the “green problem”). This is usually accomplished either by designing the cavity to resonate in a single longitudinal mode, or in a great many modes, perhaps more than 100.

The reduction in cost of laser-diode arrays has allowed manufacturers to offer frequency-doubled or frequency-tripled systems at prices that are competitive enough that DPSSLs have largely replaced ion lasers in many visible-light applications. The trend clearly favors these frequency-tripled DPSSLs in ultraviolet (UV) applications as well. These include direct-to-plate printing, drilling holes for PC-board manufacturing, medical diagnostics and research, image recording, material processing, and semiconductor metrology. A noteworthy entry here is the new Spectra-Physics Vanguard system, a modelocked Nd:YVO4 laser with an impressive 4-W output at 355 nm.

On the horizon

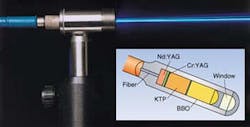

A different approach to producing UV output is provided by the passively Q-switched microchip laser. This design creates a sandwich of miniature crystals—laser, saturable absorber, frequency converting—that are bonded directly to the fiber output of a laser-diode pump (see Fig. 2). One advantage of the very small size of this DPSSL is its ability to produce Q-switched pulses that are about as short in duration as less-energetic modelocked pulses.Bonding the laser crystal to a heat sink, rather than to the pump source, is used in another new development—kilowatt-class DPSSLs for industrial markets. So-called “disk lasers” use wafer-shaped crystals that are surface pumped by many kilowatts of laser-diode power. The commercialization of high-power 940-nm indium gallium arsenide laser-diode arrays for telecommunications applications has led to the use of ytterbium (Yb) in place of Nd as the laser species for some high-power systems. It is more efficient at converting pump light than Nd, resulting in less waste heat in the crystal.

High-power laser-diode research itself is an intensive effort, and it continues to provide new pump sources. The availability of AlGaInP red laser diodes underlies research into pumping chromium-doped laser crystals such as alexandrite or LiCAF, which are tunable over 100 nm in the near infrared. These promise some of the benefits of a Ti:sapphire laser, such as ultrafast pulsed output, without the complication of a separate DPSSL pump source. And if GaN technology lives up to its potential to provide reliable high-power laser diodes with UV output, this could lead to the development of entirely new DPSSLs that produce visible output without frequency conversion.

Next month the series examines advances and applications in tunable solid-state lasers.

About the Author

Stephen J. Matthews

Contributing Editor

Stephen J. Matthews was a Contributing Editor for Laser Focus World.