Surface-emitters take on high power

Grating-coupled surface-emitting lasers promise better beam quality than conventional edge-emitters. The big question is whether they can combine beam quality with high power.

Vertical-cavity surface-emitting lasers have displaced traditional edge-emitters in such low-power applications as low-cost fiberoptic transmitters. But edge-emitters remain the pacesetters in applications requiring high-power semiconductor lasers. Now refined versions of another surface-emitting semiconductor design, the grating-coupled surface-emitting laser, are trying to crack the high-power diode market.

Edge-emitters have proven their worth for generating raw optical power to pump solid-state and fiber lasers, and the fiber amplifiers used in fiberoptic communication systems. Two types of edge-emitters are in wide use-broad-area lasers with a single emitting aperture, and diode-laser bars that emit from many discrete stripes along their length. Broad-area lasers can generate more than a watt in a continuous beam; bars can generate tens of watts. Stacks of bars can generate even higher powers, although cooling becomes an issue.

Yet edge-emitters have important limitations, including poor beam quality, high divergence, and vulnerability to surface damage. Edge-emitting semiconductor lasers work well as pump lasers because their light can be coupled directly into the gain medium or to an optical fiber. But their high-power beams can’t be tightly focused or transmitted over long distances. The only way edge-emitting semiconductor sources can generate high-quality beams is by pumping fiber or solid-state lasers, at the inevitable cost of lower overall efficiency. At least in principle, grating-coupled surface emitters should be able to combine high power with good beam quality.

For now, diode-pumped solid-state lasers are good enough for the U.S. Pentagon, which is trying to develop one for use as a 100-kW laser weapon. (see Laser Focus World, September 2004, p. 61). But the Defense Advanced Research Projects Agency (DARPA) has announced a new program to develop diode-laser systems that can directly produce a 100-kW-class beam with near-diffraction-limited beam propagation through the atmosphere. Grating-coupled surface-emitters are in the running.

Edge- and surface-emitters

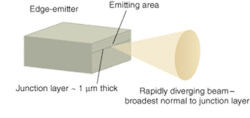

The differences between edge- and surface-emitters are fundamental to their structure and their optical properties. Edge-emitters confine light to the junction plane where carriers recombine to generate excited states and produce stimulated emission. Reflection from the ends of the junction layer produces laser oscillation, with light emerging from one of the facets-normally the other is coated with a reflective layer. The junction layer is extremely thin, so diffraction causes the beam to diverge rapidly in the direction perpendicular to the junction layer (see Fig. 1). The width of the emitting area is much wider than the height, so diffraction and beam divergence are lower in the junction plane, but the beam is still broad and multimode. The small emitting area also makes power density high, increasing the risk of optical damage to the surface.

The emitting area of a surface-emitter depends on cavity design rather than the thickness of the active layer, so it can be made much larger to reduce power density and improve beam quality. The most well-known type is the vertical-cavity surface-emitting laser (VCSEL), which places reflective surfaces or multilayer stacks above and below the active layer, so laser oscillation is normal to the active layer. While VCSELs are efficient and inexpensive, output power is limited because they collect stimulated emission from a very small volume of active layer.

One alternative is to deflect light oscillating in the horizontal plane of the junction layer so it emerges from the surface rather than the edge of the chip. One early design etched a 45° mirror into the active layer so light was deflected from the top of the chip at a 90° angle to the junction layer. A refined version of that approach is now being used by Quintessence Photonics (Sylmar, CA) to provide a high-power alternative to edge-emitters (see “A new approach to high-power surface-emitting 2-D arrays,” p. 145), but they suffer many of the same limitations on beam quality as edge-emitters. A second alternative that offers better beam quality and high brightness is grating-coupled surface-emitters, in which a second-order grating in the active layer scatters light so it emerges from the surface.

Single or arrays

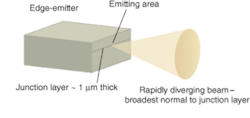

Grating-coupled surface-emitters can be made singly or in arrays. A simple single laser module has the output coupler in a passive region between two gain regions excited by the drive current (see Fig. 2). Light oscillates in a resonant cavity in the active layer formed by distributed Bragg reflectors, which are first-order gratings that reflect light in the junction plane. The second-order grating at the center of the chip scatters light out of the active layer; if the grating is transparent, the light goes both up and down. The size of the second-order grating determines the size of the emitting area. Output power depends on the length of the cavity and the drive current.

Serious work on grating-coupled surface-emitting lasers began in the mid-1980s under a military program called PILOT (Phase Integrated Laser Optical Technology). The goal was to generate high-power, high-quality beams by coherently combining emissions from a linear array of grating-coupled surface-emitting lasers. Coherent addition of the beams proved difficult because the phase of light from the output couplers was hard to control. Although the program never reached its objectives, it did plant the seeds for further development.

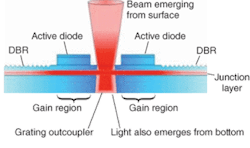

One interesting twist is addition of an external cavity to a grating-coupled surface-emitter, creating a three-port device that allows wavelength tuning or amplification of the output (see Fig. 3).1 One output is an edge facet in the junction plane of the chip, which forms part of the resonant cavity and functions as a spectrum monitor. A grating on the other end of the cavity scatters light up and down out of the active layer, so the light emerges from the top of the laser and from the substrate. The angle is set by the grating design. External-cavity optics are assembled on the grating-coupled output in an arm that ends with a highly reflective mirror. Diffraction from the grating also couples light out of the cavity through the substrate.

Driving the structure with short electrical pulses could produce tunable picosecond pulses.2 It also could be modelocked by modulating the drive current at the fundamental frequency of the external cavity. Modelocking at 297 MHz was demonstrated in a MOPA (master oscillator/power amplifier) configuration at the University of Central Florida with the final stage a grating-coupled semiconductor optical amplifier or similar design.

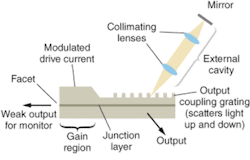

At Southern Methodist University in Dallas and a spinoff company called Photodigm (Richardson, TX), Gary Evans has been developing pulsed grating-coupled lasers for applications in optical communications and laser radar. The output coupling grating is located in a passive part of the laser, where no drive current flows. That gives the coupling grating the same dependence on temperature and effective refractive index as the distributed Bragg reflectors (DBRs) on the edges of the laser chip, which keeps the output beam stable despite changes in temperature and drive current.

A channel in the active layer guides light between the DBRs on either end of the cavity, with a second-order grating between the DBRs. They initially made 1310-nm surface-emitters for fiberoptics, then turned to higher-power short-pulse arrays for laser radar.3 Increasing the length of the active-layer stripe increases total power and the fraction of light coupled out of the second-order grating. Linear arrays use every other gain section as a phase-shifter to control beam quality-another option is using a single large grating output coupler to keep the output in phase. So far their grating-coupled arrays have reached peak powers of 5 W at 1550 nm-for use in eye-safe laser radars-with duty cycles of 0.1% to 1%. Evans hopes the design can reach peak powers of 15 W.

Changes yield higher power

Aiming for higher continuous-wave powers while maintaining good beam quality, Dan Botez’s group at the University of Wisconsin in Madison has made some subtle but important changes in the basic design of grating-coupled surface-emitters.

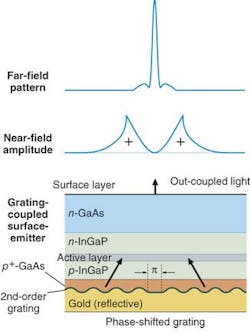

Some changes are at the level of individual laser elements. One places the output grating primarily in the zone of the laser through which current flows, so it functions as a distributed feedback grating, rather than only in the passive regions where no current flows. A second change is to add a central phase shift of 180° in the DFB grating, which gives the near-field amplitude a symmetric profile rather than the asymmetric near-field profile without the phase shift (see Fig. 4). In the far field, the 180° phase shift creates a single-lobe beam with no penalty in device efficiency.4, 5

Another key change is in the assembly of 2-D arrays of surface-emitting-laser elements. Normally, laser emission is laterally confined in a high-refractive-index region by a waveguide effect. However, Botez’s group uses a 1-D active photonic crystal (a periodic variation in the dielectric constant) with the DFB output coupling gratings placed in the low-index regions. This creates a resonant optical waveguide structure that supports traveling waves, and can resonantly excite an entire 2-D array. In principle, the array output should reach at least 2-W continuous wave in a single mode.6

Outlook

Watts of continuous-wave power from a grating-coupled surface-emitter would be an impressive achievement, roughly a thousand times the power available from electrically excited VCSELs. It also might open the door to scaling upward with larger two-dimensional arrays.

Researchers are hoping for a boost from a new DARPA program, “Architecture for diode high-energy laser systems” or ADHELS, an effort “to generate high-power, high-brightness laser beams of military interest by combining the beams of high-power, high-efficiency laser diodes/arrays/stacks.” Although it doesn’t spell out an interest in surface-emitters, it leaves the door open for further development.❑

ACKNOWLEDGMENTS

Thanks to Dan Botez, Gary Evans, Chandra

REFERENCES

1. K. Kim et al., Optics Lett. 29, 1273 (Jun 1, 2004).

2. O. Smolski et al., Proc. SPIE 4651, 59 (2002).

3. T. Masood et al., IEEE Photon. Tech. Lett. 16, 726 (March 2004).

4. S. Li et al., IEEE J. Sel. Topics in Quant. Electronics 9, 1153 (Sept.-Oct. 2003).

5. D. Botez, Laser Focus World 40, 82 (April 2004).

6. S. Li and D. Botez, IEEE Photon. Tech. Lett. 17, 519 (March 2005).

7. G. Witjaksono et al., Appl. Phys. Lett. 83, 5365 (Dec. 29, 2003).

A new approach to high-power surface-emitting 2-D arrays

Cooling can be the killer with the “rack and stack” approach to assembling two-dimensional arrays of edge-emitters. Each bar needs to be pressed against a cooler with liquid flowing through microchannel cores to remove the excess heat. The power levels are impressive, but so is the mechanical complexity and the number of separate parts that have to be assembled.

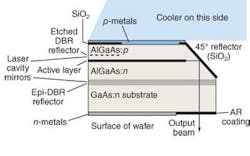

Quintessence Photonics has developed a new approach to 45° coupling of light from the active layer out the laser surface. The laser cavity is formed by a pair of reflectors, one DBR grating in the junction layer, and one between the 45° total internal reflector and the surface, as shown in the diagram. The entire structure is fabricated photolithographically, with the 45° reflector directing the beam through the transparent substrate. Many laser elements can be made on the same substrate, forming a monolithic 2-D array, which can be cooled easily from the bottom, with outputs automatically aligned.

Output characteristics are similar to those of edge-emitters. To date, arrays of about 250 laser elements have generated up to 300 W, but Quintessence says that powers up to a kilowatt should be possible.