40 Years Then and Now: CD technology takes the fast track

Over the years, the scope of Laser Focus gradually expanded from covering just lasers and their applications to covering the entire field of light-based technology, inspiring its editors in January 1989 to rename the magazine Laser Focus World. Back in 1965, however, Laser Focus was the publication that had the world’s sharpest focus on lasers.

Because lasers have become useful in so many ways in the intervening 40 years, it is easy to riffle through an early issue of Laser Focus and find many instances of then-esoteric technology that have since blossomed and become essential to some part of everyday life. Of all these, there is one application that overshadows the rest, at least in terms of the number of lasers in use and the many places they are used: CD reading and writing (which has grown to include DVD reading and writing).

null

In a big way

The first instance of optical-disc technology in Laser Focus appeared in the March 1, 1965, issue (turn to page 3 if you have the issue handy). “Lasers suddenly appear to have arrived on the computer and electronic-data-processing scene in a big way,” begins the story. “Designed as the Memory-Centered Processor MPC-1000, the new equipment features a photo-optical online random-access mass memory capable of storing up to a trillion bits of data, which are written on coated plastic discs by 6,328-angstrom light produced with a 27-mW helium-neon continuous-wave laser.”

Designed at Itek (Lexington, MA), the several-foot-long MPC-1000 actually contained a large “jukebox” that held 650 10-in.-diameter, 0.03-in.-thick discs, each storing 200 Mbits of data; a traveling sickle-shaped picker arm selected individual discs. “The system-largely because of the role played by the laser data writer-is priced at $500,000, or only 0.00009 cent per bit.” Although that sounds like a bargain, CD music players are available today at local pharmacies-and even convenience stores-for about $20. Considering that an average music CD today can hold 700 Mbytes of information, which equals 5.6 Gbits of info, today’s cost per bit translates to 3.6 × 10-7 cents. This improvement, by a factor of 250, is actually quite low when comparing an exotic early prototype with the ultimate in mass production-but the cost per bit of the Itek system was greatly improved by its inclusion of a jukebox.

“A major disadvantage of the MCP-1000 in many applications is that its photo-optical memory stores data in a permanent form-that is, the discs cannot be erased and used over again, but must be discarded if the data on them is no longer valid. For applications requiring archival permanence and quality, this characteristic is, of course, beneficial.” As far as CD discs go today, things are no different-at least for the basic write-once version, which is quite useful for backups and archival storage. It is, indeed, also useful for the common task of copying computer files to transfer to another computer, but only because its storage size is so much larger than the size of many files. Today, however, e-mail is taking over as the preferred mode for the transfer of files between computers.

The rewritable version of today’s data CD can be overwritten about a thousand times before it becomes unreliable. Advances in materials have made this possible: a layer of polycrystalline metal in the CD becomes amorphous upon heating by the laser in the CD write head, writing a bit; laser-heating at a lower power allows recrystallization to occur, erasing the bit.

Developing technology

In contrast, the disc material in the Itek MCP-1000 contained photographic emulsion. Before first use, a disc was delivered to the writer-processor by the jukebox. “A programmed counter imprints a disc serial number on each blank. This number is then recorded-or, more correctly, ‘burned’-into the photo-emulsion surface at the disc’s first data-track position by the laser. All other data are recorded in the same manner.” (Today we still “burn” CDs.) After writing, the disc entered a developer, where the data was fixed in a few seconds.

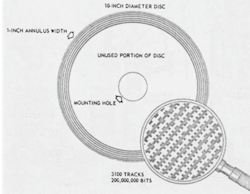

The data tracks of current CDs and DVDs consist of single-file trails of pits separated by spaces. The discs for the Itek machine, however, had a more complicated layout (see figure). “Each data bit is made up of two cells, one clear and one dark. The sequence of cell pairing determines whether the bit is in the binary ‘zero’ or binary ‘one’ state. These two-cell bits are recorded on a five-micron-wide data track; a total of 3100 tracks-capable of holding 25 million characters-are recorded on a one-inch annulus at the outer edge of the disc.

“Each data track is bounded on one side by an all-dark track and on the other side by an all-clear track. These identifying boundary tracks permit closed-loop servoing by the disc reader and eliminate the necessity of maintaining close tolerances on track concentricity.” Today’s CD readers also use closed-loop tracking, but use back-diffracted fringes resulting from the pit trail itself as a servoing signal.

Among the many advances in optical-disc technology since 1965, the development of the inexpensive, reliable, high-beam-quality semiconductor laser stands out. The first practical CD devices relied on near-IR laser diodes; now, red-emitting laser diodes allow DVD tracks to be packed closer together. Already, the capabilities of blue-emitting gallium nitride-based semiconductor lasers are being exploited to further reduce spot size and increase disc capacity.

Sony (Tokyo, Japan) has brought to market a blue diode-based DVD recorder that increases single-sided single-layered DVD data capacity from 4.7 to 23 Gbytes, using the co-called “Blu-ray” technology and format. Blu-ray is supported by Sony, the Walt Disney Company (Burbank, CA), and other large corporations. A rival blue-diode disc format called HD-DVD is supported by NEC and others; a standards war rivaling the VHS/Betamax videocassette wars of the last century may well be the result (see Laser Focus World, June 2004, p. 31).

Inside Laser Focus February 1965

- Laser, whither thou goest?

- British report on developments in laser ophthalmology

- Laser proven to be a superior measuring standard

- Non-doppler laser speed sensor developed

- Wind velocity measured by ring laser

- Argon laser achieves four-watt output

- Efficient, high-power focuser demonstrated

- Magnetism controls laser intensity

- Lasers aid in long-distance waveguide evaluation

- Versatile duo-laser biomedical system announced

- Ultraprecise optical cavity developed

- Some feedback on laser health hazards

- Optical transition terminology clarified

- Laser surgery joins two arteries

- Two laser-operated photochromic memories proposed

- Laser studied as stimulator for ion engine

- Milling machine aligned via laser

- Oscillations in neodymium-doped laser under study

- More on magnetic intensity control of lasers

- Light modulator produces single sidebands

- Laser action ‘caught’ with new ultrafast camera

- Two lasers locked in phase for the first time (see photo)