Organic thin film lases in the UV

Laser-active solid-state materials made of organic compounds have already proven their capabilities throughout the visible spectrum. Their potential derives from intrinsic advantages such as the broad tuning range of a selected organic compound, the many compounds available, and the ease of engineering practical devices. Drawbacks include the difficulties of achieving direct electrical excitation (see Laser Focus World, September 2000, p. 19, for a successful implementation) and the lack of compounds that emit in the UV.

Considerable application is foreseen for inexpensive electrically (as well as optically) pumped organic UV-laser sources in biology, medicine, and the pharmaceutical industry. Other potential applications include data storage and reading, as well as printing-areas in which inorganic diode lasers, gas lasers, dye lasers, or frequency-converted solid-state lasers could be replaced by low-cost organic lasers.

Now, a UV-emitting organic device has been developed by researchers at the Technical University of Braunschweig, the Physikalisch-Technische Bundesanstalt, (both of Braunschweig, Germany) and Covion Organic Semiconductor (Frankfurt, Germany).1 Though optically pumped, the organic compound is semiconducting, and hence is worth further efforts to achieve electrical pumping.

The novel laser-active medium belongs to the class of so-called spiro-linked materials, already well known from their use in organic light-emitting diodes (OLEDs). The compound chosen by the German researchers is 2,2´,7,7´-tetrakis(4-fluorphenyl)spiro-9,9´-bifluorene, which can be conveniently pumped by a nitrogen laser; its photoluminescence maximum is situated at 387 nm.

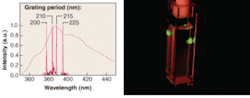

The organic layer was thermally evaporated onto a substrate that consisted of a Bragg-grating structure with various periods, etched in silicon and protected by a quartz layer so that the active medium could be operated as a second-order distributed-feedback (DFB) laser. The laser beam emanated vertically from the surface. Alternatively, to explore more-cost-effective manufacturing techniques, an olefin polymer grating (Topas 5013) molded from a silicon master was used as a substrate. The thickness of the deposited organic layer was 350 nm. Spin-coating is another possible fabrication approach; however, the substrate must not be damaged by the solvent.

The DFB structure was pumped at 337 nm using a nitrogen laser with 500‑ps pulse duration and 20-Hz repetition rate; the light was focused to a 500‑μm-diameter spot on the DFB structure. The intensity of the nitrogen laser beam was controlled using an attenuator, so that the laser power could be recorded as a function of the pump-pulse energy density. A lasing threshold of 62 μJ/cm2 was measured for emission at 382 nm; the emitter produced pulses with peak powers of up to 6.8 W.

Emission down to 377.7 nm

To demonstrate tunability, gratings of different periods were etched. Emission wavelengths useful for fluorescence-marking experiments were obtained, with 377.7 nm being the shortest wavelength obtained by a thin-film organic solid-state laser so far (see figure).

But can direct electrical excitation be achieved in the device? Thomas Riedl, head of the research group, is optimistic. “All organic materials used to build our lasers bring the ability to transport charges and emit light upon charge injection,” he says. “It works for OLEDs, so why not for lasers? Yet, the currents necessary to reach the threshold of a laser are approximately 10,000 times higher than in OLEDs-currently, too much for the organic materials. There is still some work to be done.”

Optical pumping of organic thin-film lasers is also of interest, however, because the broad photoluminescence range bears considerable potential for tunability and short-pulse generation, comparable to dye lasers. What makes them superior to dye lasers is the fact that the solid-state active medium can be designed directly as a frequency-specific cavity.

REFERENCE

1. D. Schneider et al., Adv. Mater.17(1), 31 (2005).