Diode lasers now compete with solid-state systems

Michael Mikulla and Jürgen Braunstein

High reliability, long life, and low cost of ownership are giving high-power diode lasers a foothold in what was once solid-state ground.

Compactness, improved reliability, and higher power are enhancing the status of diode-laser-based systems in a variety of applications. For example, solid-state lasers benefit from these attributes because diode lasers provide an alternative to flashlamp-pumping. These diode-based systems offer much lower maintenance, with routine service downtimes scheduled every 5000 h or longer, instead of the 500-h intervals that are typical for lamp-pumped laser systems.

FIGURE 1. Compact size of diode lasers makes it easier to integrate them with robotic systems for direct manufacturing applications. This shoe-box size laser head from Rofin-Sinar can provide up to 3 kW of CW output power.

Diode-pumped lasers also can provide kilowatt-level output. Rofin-Sinar (Hamburg, Germany) offers diode-pumped Nd:YAG lasers with output powers exceeding 4 kW. Systems offering even higher output may soon be available. Some engineers at Rofin-Sinar even believe these diode-pumped systems are more cost efficient because the lower energy costs and reduced maintenance outweigh the higher initial price tags. The result is a lower cost of ownership that may give diode-pumped systems the impetus to replace more and more lamp-pumped systems during the next few years.

Progress in diode-laser bars

Today, commercial high-power diode lasers consist of linear arrays of up to 25 single broad-area emitters in a 1-cm wide bar. Output power reaching 40 W is possible with a single bar, and stacked arrays of bars can push power into the kilowatt regime, while maintaining reliable device operation.

Osram Opto Semiconductors (Regensburg, Germany), the largest producer of high-power diode lasers bars in Europe, has driven 808-nm diode laser bars at an output power of about 40 W for tests of 4500- and 8000-h duration. In both cases, the devices showed little degradation so the extrapolated lifetime of these lasers can be near 200,000 h. During testing, the bars were mounted p-side down on water-cooled microchannel heat sinks. The packaging was done by DILAS Diodenlaser (Mainz, Germany), a Rofin-Sinar company. A 20% power decrease signaled the end of a device's life.

Moving into direct materials processing

Combining improved output power and reliability with sophisticated beam forming and focusing techniques also has given diode lasers a foothold in direct materials-processing applicationseven though beam quality remains rather poor compared to output from a solid-state laser. One manufacturing advantage is that the compactness of diode lasers facilitates their integration with robotics. An example is a Rofin-Sinar diode laser head about the size of a shoebox that can provide 3 kW of continuous-wave (CW) output with up to 30% wall-plug efficiency depending on the power supply (see Fig. 1) .

Also finding industrial use are fiber-coupled diode laser systems with output powers up to 2 kW from both Rofin-Sinar and Jenoptik Laserdiode (Jena, Germany). A typical use, and indeed one of the very first industrial manufacturing applications for such systems, is the welding of kitchen sinks with a heat-conduction welding technique. Here, the diode laser beam produces a very smooth, nicely shaped weld seam that reduces the need for a later surface-finishing step.

Until now, these diode-laser systems had a beam parameter product between 100 and 1000 mmmrad, which excluded them from traditional high-power laser applications such as cutting or deep-penetration welding of metals. But even these barriers are crumbling.

FIGURE 2. Thermal conductivity of water-cooled microchannel heat sinks with 1-cm-wide diode-laser bars with a 2-mm resonator length mounted p-side down was measured to be smaller than 0.29 K/W. Output power of the diode-laser bars reached a maximum of 267 W CW at 333 A with an electro-optical conversion efficiency of 40%.

Researchers at the Fraunhofer Institute for Laser Technology (ILT) recently demonstrated deep-penetration welding of stainless steel sheets 2-6 mm thick with a modified Rofin-Sinar diode laser and optimized process control. Although work is still necessary to boost processing to speeds competitive with solid-state lasers, the experiment demonstrated the strong potential of diode-laser sources to replace expensive, inefficient solid-state lasers in direct materials-processing applications within the next years. The speed of this transition will depend on further improvements in output power and beam quality of the diode-laser bars.

In Germany, the development of high-power diode lasers at the Fraunhofer-Society involves a joint venture between the Institute for Applied Solid-State Physics (IAF) and the ILT. The first institute will emphasize development of the diode-laser bars, while the second will develop the microchannel copper heat sinks, as well as mount and test the devices. Project goals include the improvement of both the output power of single diode-laser bars and the reliability of laser systems.

The epitaxial layer sequence used by ILT for the high-power diode lasers consists of a single indium-gallium-arsenide quantum well as the active region embedded in an aluminum-gallium-arsenide (AlGaAs) core region with a low aluminum content. The optical waveguide is formed by AlGaAs claddings with a higher aluminum content.

From these wafers, scientists have fabricated broad-area laser bars that comprise up to 25 individual emitters with an output aperture of 200 µm and a pitch of 400 µm (50% fill factor). Diode-laser bars 1 cm wide with 2-mm resonator length were mounted p-side down on water-cooled microchannel heat sinks at the ILT.

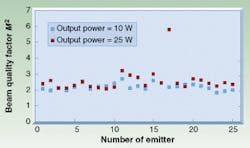

FIGURE 3. A near-diffraction-limited average beam quality parameter of M2 = 2.6 has been demonstrated for emitters that make up a single diode-laser bar.

The resulting heat sink produces thermal conductivity below 0.29 K/W (see Fig. 2). The CW output power reaches a maximum of 267 W at 333 A with an electro-optical conversion efficiency of 40%. This may still be the highest output power ever received from a single 1-cm diode-laser bar. With lower thermal load, at 170 A and 150 W of output power, the conversion efficiency is as high as 50%, and the corresponding slope efficiency is 0.9 W/A. The emission wavelength is 980 nm at 100 A.

Using another approach, the IAF has developed diode-laser bars with improved beam quality for each emitting diode. The process uses tapered laser oscillators as emitting diode lasers, in essence replacing broad-area emitters. Each diode-laser bar comprises 25 of these emitters. Typical output power of these bars is between 25 and 30 W CW at room temperature with a conversion efficiency of 35%.

The single emitters show a remarkable beam quality with good uniformity along the bar (see Fig. 3). Although results surpass the beam quality of conventional broad-area lasers by more than an order of magnitude, this gain comes with a pricenamely, stronger demands on the beam-collimating optics due to the astigmatic beam profile, the lower conversion efficiency, and lower output power.

Future view

High-power diode-laser research discussed in this article was supported by the German government in the framework of the Laser 2000 program and the recently initiated program called Modular Diode Laser Tools. The programs allowed a strong partnership between research institutes, industrial companies that develop and produce diode lasers, and the numerous users of these tools who are responsible for a quick implementation of diode-laser systems in industrial applications. Combined, these efforts continue to knock down a variety of barriers.

On one research front, in the near future, end users can expect reliable diode-laser bars with up to 100 W of CW output power, which will improve their competitiveness against solid-state lasers.

On the other hand, there is still a strong demand for improved beam quality from diode-laser bars in order to increase the speed in materials-processing applications. Currently, the tapered diode-laser array appears to be the most promising approach to meet this requirement.

ACKNOWLEDGMENTS

The authors gratefully acknowledge numerous colleagues for their contributions to this article. Special thanks to Dr. M. Behringer from Osram Opto Semiconductors and Dr. F. Bachmann from Rofin-Sinar for data provided in Figure 2.

MICHAEL MIKULLA and JÜRGEN BRAUNSTEIN are research scientists at the Fraunhofer Institute for Applied Solid-State Physics, Tullastrasse 72, D-79108 Freiburg, Germany; e-mail: [email protected].