LIGHT-EMITTING DIODES: Geometry boosts visible LED efficiency

Used in traffic lights, large-screen displays, and automobile brakelights, high-output visible-spectrum light-emitting diodes (LEDs) may eventually become practical for room illumination. To be of any benefit to the consumer world, improvements in LED efficiency must not come with a high price tag. Now, researchers at Agilent Technologies (San Jose, CA; formerly Hewlett-Packard Optoelectronics Division) are building visible-spectrum encapsulated LEDs that have record optical efficiency and are doing so using a simple geometric chip-shaping technique suitable for mass production.

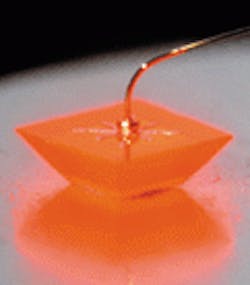

The researchers fabricate an LED chip in the shape of a truncated inverted pyramid (TIP), thus creating a device that redirects side-emitted light via total internal reflection and causing the light to exit along the chip's intended output axis (see photo). Although chip-shaping has been tried before as a means of extracting more light from an LED, until now, no practical technique has been developed.

"Previous techniques were impractical for high-volume manufacturing because of reduced device yield per wafer due to shaping," explains Mike Krames, an engineering scientist at Agilent. "Also, the methods were not suitable for batch- or wafer-level processing, or for precise control over the final geometry." In the new approach, an angled dicing blade shapes the chips at the wafer level and offers tight control over final geometry.

Made from aluminum gallium indium phosphide/gallium phosphide (AlGaInP/GaP), the LEDs have center wavelengths that fall between 580 and 650 nm. A typical device has a junction area of 0.25 mm2, a sidewall angle of 35°, and are mounted into high-power packages. Efficiencies are anything but ordinary: an orange-emitting (610 nm) device has exceeded a luminous efficiency of 100 lm/W, while a red-emitting (650 nm) LED has reached an external quantum efficiency (QE) of 55% and a wall-plug efficiency of 45%. "As far as we know, 45% wall-plug efficiency and 55% QE are the highest ever reported for an encapsulated visible-spectrum LED," says Krames.

In conventional LEDs, external QE is limited by internal optical losses that include reabsorption of light by the active layer. For short-wavelength AlGaInP LEDs, a design trade-off between reabsorption and electron confinement results in an optimum active-layer thickness that reabsorbs a significant amount of light. Extracting light by modifying chip geometry permits a reduction in photon path length. When the researchers compared an LED based on TIP geometry to an otherwise similar but conventional LED, they found that the change in geometry resulted in a 1.4X improvement in external QE. According to the researchers, a dropoff in external QE at higher electrical currents is due to increased junction temperature, as the thermal resistance of the device is limited by the die-attach interface and the thermal resistance of the test fixture. (This is true for conventional LEDs as well. Improved performance is expected in application through use of proper thermal-management techniques.)

When subjected to accelerated-degradation tests and temperature-cycling stress tests, the TIP LEDs perform as well as conventional devices, say the researchers. The peak observed luminous efficiency of 102 lm/W for the orange LED exceeds the luminous efficiency of most fluorescent lamps, they add.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.