NONLINEAR MATERIALS: Waveguide devices mix frequencies of diode lasers

KONSTANTIN P. PETROV, DOUGLAS J. BAMFORD, and THOMAS L. PATTERSON

Optoelectronic devices are evolving rapidly, not only in terms of performance, but also in the level of integration. Epitomized by the use of optical waveguides and fibers, optoelectronic systems are beginning to resemble electronic circuits. Optical analogs of electronic-circuit elements include diode lasers, detectors, modulators, switches, and attenuators—all of which provide an electrical-to-optical interface. The underlying purpose of this evolution is a higher level of integration of the optical and electrical functions within the same device, the intent being that the components appropriate to both functions would eventually be fabricated using similar process steps on a common substrate.

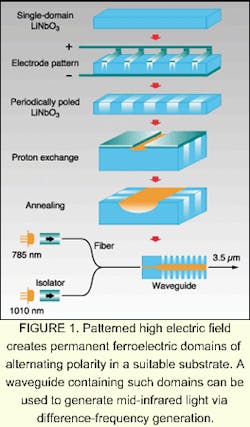

Among the recent developments in optical-waveguide technology are nonlinear optical waveguides that can mix two input laser frequencies and create an additional output at the sum or difference frequency. They are fabricated in nonlinear optical crystals that lend themselves to quasi-phase-matching, a technique used for synchronizing the phase velocities of interacting waves. Examples are potassium titanyl phosphate (KTP) and lithium niobate (LiNbO3)—birefringent nonlinear crystals that have ferroelectric properties at room temperature. With the application of a patterned high electric field, a sequence of permanent ferroelectric domains of alternating polarity can be created whose period can be selected to provide efficient interaction of a given set of laser wavelengths.

Waveguides increase interaction length

Fabrication of periodically poled KTP and LiNbO3 has recently become routine. While these two bulk materials are commonly used in nonlinear-optics applications, it is their ability to host waveguides that has made them the subject of intense development in recent years. Waveguide channels can be formed in these materials by titanium indiffusion or ion exchange. Light in the waveguide is carried as a set of discrete optical modes confined to a channel only a few microns wide, leading to local field intensities exceeding 100 kW/cm2. Unlike traditional bulk optics where diffraction limits the interaction length of focused laser beams, properties of the waveguide mode are maintained along the entire length of the waveguide, leading to an interaction 100-1000 times more efficient and hence to numerous possible applications.

Researchers at Matsushita Corp. (Tokyo, Japan), for example, have used a proton-exchanged waveguide in MgO:LiNbO3 for highly efficient (31%) single-pass frequency doubling of an 860-nm diode laser.1 A group at Stanford University (Palo Alto, CA) has developed tapered waveguides, in conjunction with directional couplers, capable of channel-shifting in the 1.5-µm communications band using the process of difference-frequency mixing with a 780-nm pump laser.2

Another application of nonlinear optical waveguides is the generation of mid-infrared (IR) wavelengths that are inaccessible by other solid-state lasers. Tunable radiation in the 2-5-µm spectral fingerprint region has proven to be a powerful tool in trace-gas detection and has potential applications in medical and combustion diagnostics. But to date there are only a few laser sources that can operate in this wavelength region, and most of them suffer from one or more technical drawbacks that preclude their use in field instruments.

Gas lasers such as carbon monoxide and helium-neon devices deliver enough output power but are generally bulky, require significant electrical power, and can only be operated on a set of discrete wavelengths. Lead-salt lasers and color-center lasers are tunable but require cooling near the temperature of liquid nitrogen for normal operation. Optical parametric oscillators deliver significant output power at room temperature and cover a wide range of wavelengths, but their linewidth and fine-tuning characteristics make them difficult to use in high-resolution spectroscopy. A new breed of IR semiconductor laser, known as a quantum-cascade laser, is now being developed that has the potential to reach narrow-linewidth, continuous-wave operation at room temperature.

A possible alternative to these sources is based on difference-frequency mixing of commercial diode lasers (see Fig. 1). Such a source consists of two diode lasers (pump and signal) and a mixing element in the form of a nonlinear optical waveguide. While generating tens of microwatts of continuous-wave IR light (the idler), it inherits the room-temperature operation, reliability, small size, and excellent tuning behavior of commercial near-IR diode lasers. Several such sources have been developed at Gemfire Corp. (Palo Alto, CA). Each one is based on a three-stage integrated channel waveguide fabricated by annealed proton-exchange in periodically poled LiNbO3.

Periodic poling and waveguide-channel lithography are performed on standard 3-in. wafers of z-cut congruent LiNbO3. Periodic poling with periods ranging from 17 to 20 µm is performed by application of a 200-ms pulse of electric field of magnitude greater than 24 kV/mm. The waveguides are fabricated on 25 x 8-mm chips, each carrying a metal mask with waveguide channel openings. The chips are first subjected to proton exchange in molten benzoic acid at 160°C to form waveguide channels up to 20 µm wide and about 1 µm thick. The chips are then annealed in an air-filled tube furnace at 340°C. This allows the protons to diffuse deeper into the substrate material, making the waveguide channels closer to axially symmetric.

Mode filter boosts efficiency

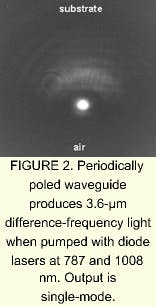

When pumped with diode lasers at 787 and 1008 nm, the waveguides exhibit conversion efficiency of up to 4 %/W at the operating wavelength of 3.6 µm. With less than 200 mW of total laser power launched into the waveguide channel, the difference-frequency output power exceeds 140 µW. The output beam is approximately 12 µm in diameter, is diffraction-limited, and has a single-mode structure as determined by the properties of the waveguide core (see Fig. 2). The core is designed to carry a single spatial mode at the idler wavelength, which makes it necessarily multimode at the shorter pump and signal wavelengths. The presence of higher-order modes is generally undesirable because it leads to a poorly controlled distribution of coupled laser power among the possible modes. As a result, the nonlinear interaction between pump and signal waves becomes more complicated and significantly less efficient.

To solve this problem, each difference-frequency-generation waveguide section is connected to a narrow waveguide that functions as a mode filter via a waveguide taper. The mode filter is designed to carry one or two modes at the pump and signal wavelengths and is optimized for coupling of pump and signal light using traditional optics or an optical fiber. Following the mode filter is a tapered section in which the pump and signal modes are transformed for coupling into the mixing waveguide. If the taper is long enough, the transformation occurs adiabatically—that is, without an appreciable leakage into substrate or excitation of higher-order modes.

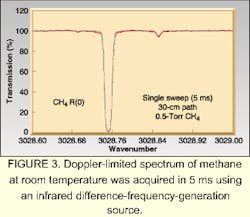

The output spectral linewidth of the difference-frequency source is a convolution of the spectral linewidths of the pump and signal lasers and is less than 30 MHz. These performance characteristics, combined with a fine-tuning range of more than 60 GHz, make the source suitable for high-resolution spectroscopy and gas detection (see Fig. 3). Excellent agreement between measured and theoretical spectra suggests that a real-time, accurate quantitative measurement of trace gases is feasible with the use of this technology.

Diode-pumped nonlinear waveguide technology may eventually develop to the point where an entire optical path—including optical isolators, routing waveguides, directional couplers, a mixing element, and a miniature sampling volume—could be incorporated into a single chip. Drive circuitry, lasers, and detectors could be attached to this chip. This would create a breed of small, inexpensive, smart chemical sensors similar in concept to the elusive "lab on a chip" and may indicate the shape of optoelectronic devices to come.

REFERENCES

- T. Sugita, K. Mizuuchi, Y. Kitaoka, and K. Yamamoto, Opt. Lett. 24, 1590 (1999).

- M. H. Chou, J. Hauden, M. A. Arbore, and M. M. Fejer, Opt. Lett. 23, 1004 (1998).

Konstantin P. Petrov is a hardware-development engineer, Douglas J. Bamford is director of the sensor program, and Thomas L. Patterson is a development engineer at Gemfire Corp., 2471 East Bayshore Road, Ste. 600, Palo Alto, CA 94303; e-mail: [email protected].