SOLID-STATE UV SOURCES: All-solid-state system offers alternative to excimer laser

Narrow bandwidth and low power from a solid-state UV source could improve production-line reliability.

Jeremy Weston and Ron Olson

Tunable-laser sources have been the backbone of many significant areas of laser research, including photochemistry, spectroscopy, and laser remote sensing. Since the mid-seventies, Nd:YAG pumped dye lasers have been workhorses in laboratories around the world. The advent of tunable solid-state laser systemssuch as Ti:sapphire lasers and optical parametric oscillators (OPOs)brought a previously unheard of level of performance and reliability. Predictably, however, commercialization of applications requiring high spectral brightness (narrow linewidth) has been slow, due in large part to the complexity and size of these tunable systems. At Positive Lightunder a license with Stanford Universitywe have developed a new-generation compact, tunable solid-state laser that fills the need for a narrow-bandwidth, broadly tunable system. It is finding applications in mobile, airborne, and industrial environments, as well as in the laboratory, and it shows particular promise in deep ultraviolet (DUV) lithography.

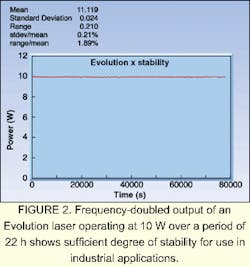

In 1998, Positive Light introduced the Evolution, a diode-pumped Nd:YLF laser with output powers in excess of 10 W for Q-switched, 150-ns pulses at 527 nm. At about the same time, the Stanford Ti:sapphire system was constructed using a high-energy (flashlamp-pumped) Nd:YAG laser. Combining these two technologies produced a Q-switched diode-pumped Nd:YLF laser with a single-mode Ti:sapphire oscillator having a fundamental output that is tunable from 720 to 920 nm for 7-10-ns pulsewidth energies up to 1 mJ (800 nm) at a repetition rate of 1 kHz.

Excimer lasers operating in the DUV currently dominate the lithography industry as production workhorses. Laser manufacturers, such as Cymer (San Diego, CA) and Lambda Physik (Fort Lauderdale, FL), provide stepper and scanner manufacturing companies like SVG Lithography, Canon, and Nikon with both krypton and argon fluoride (KrF and ArF) lasers to facilitate chip designs with feature sizes as small as 0.18 µm. The performance and reliability of these systems is a key element in perpetuating Moore's Law. But excimer lasers have drawbacks, including their size, operating cost, and utility requirements. These are especially significant when the lasers are used in non-production applications such as metrology and system alignment. Our new Indigo system promises to fill this vacuum in the deep UV.

Metrology

Within chip fabrication, the widespread use of excimer lasers operating at 248 nm (KrF) and 193 nm (ArF) has led to something of a contest among commercial laser suppliers. The challenge is to produce low-power, long-coherence UV lasers to be used in various applications, including metrology. Suppliers to the semiconductor fabrication industry, including those mentioned above, use large excimer lasers as production tools in steppers and scanners. But with ever-smaller device feature sizes, the need for improving in-house optical testingand that of their suppliersis magnified. Typically, optics are examined using interferometry. In this technique, the wavefront distortions caused by the introduction of an optic in one arm of an interferometer are examined in real-time using a narrowband (long-coherence) laser. Currently, the majority of interferometers are based on HeNe lasers emitting at 633 nm, which necessitates wavelength scaling and reduces accuracy.

Creating a narrow-bandwidth, low-power alternative to an excimer laser has led to some fairly complex schemes. One of these involves mixing the fifth harmonic of a Nd:YLF laser with the output of an OPOnot exactly a process either production or fab engineers relish.

Using a diode-pumped solid-state (DPSS) Nd:YLF pumped Ti:sapphire package we have developed a straightforward harmonic-generation technique for obtaining a stable, narrowband UV output. The system consists of a Positive Light Q-switched, diode-pumped Nd:YLF laser (Evolution) and a single-mode Ti:sapphire oscillator developed by Stanford researchers Andrew Merriam and G. Y. Yin (see photo on p. 133 and on cover). The fundamental output is tunable from 720 to 920 nm for 7- to 10-ns pulses with energies up to 1 mJ (800 nm) at a repetition rate of 1 kHz. The linewidths are user-adjustable from single-mode (<0.01 pm) to extremely broadband (>50 nm) by eliminating (blocking) an optic. Optional harmonic-generation stages can be specified to produce second-harmonic (200 µJ at 400 nm), third-harmonic (75 µJ at 266 nm), and fourth-harmonic outputs to 193 nm.

Until recently, the preferred means of obtaining single-mode tunable output involved injection seeding a Ti:sapphire oscillator using single-frequency laser diodes as the seed source. The shortcomings of these systems are somewhat intuitive, given the myriad subsystems involved: injection seeding is difficult to maintain, and "tuning" amounts to switching seed-laser sources. Such a system is operating at Stanford University's Ginston Laboratory where it is used to generate vacuum UV at 186 nm.

Design improvements

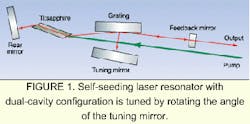

In seeking a more flexible second source, Merriam and Yin looked to improve on a design first proposed by Ko and others, which, while producing a narrow-bandwidth output, required more than 80 mJ of pump energy to produce a 3-mJ output. With a dual-cavity configuration the Stanford researchers produced a tunable self-seeding Ti:sapphire oscillator with efficiencies approaching 50% (see Fig. 1).

The dual-oscillator configuration uses a very compact design to take advantage of what has been termed mode discrimination walk-off to induce operation in a single longitudinal mode. If the short cavity, consisting of the rear mirror, a grating, and a tuning mirror, is aligned with respect to a center frequency, as determined by the grating orientation, the angle of the tuning mirror, and the reflectivity of a feedback mirror, then all adjacent (competing) modes will experience losses, as if from cavity misalignment. The oscillator is tuned by changing (rotating) the angle of the tuning mirror, and single-mode operation is observed over the entire tuning range (720 to 920 nm).

Frequency doubling in LBO produces an output of 200 µJ at 400 nm, while tripling results in 75 µJ at 257 nm. A proprietary technique for sum frequency mixing in beta barium borate BBO facilitates a fourth harmonic output of about 20 mW at 193 nm.

The fact that the Indigo system is pulsed (operating between 1 and 5 kHz) is not an issue for metrology, as long as the pulse-repetition rate is faster than the refresh rate of the detector (typically less than 100 Hz). The Indigo system repetition rate can be varied between 1 and 5 kHz as a function of the Nd:YLF pump laser. The average power output peaks at just over 2 W (5 kHz operation at 800 nm) while the energy per pulse peaks at 750 (J (1 kHz operation).

System alignment

With some stepper manufacturers using more than a dozen excimer lasers just for system optical alignment, we look to reduce the excimer's considerable operating costs and reduce the space requirements with an all solid-state set up having a footprint of 17 x 26 in. and consuming less than 1 kW with no requirement for external cooling. Noteworthy within the fabrication environmentand unlike the excimer lasers that they complementthe Indigo system is designed to be serviced within a cleanroom environment.

Production-line reliability is a major advantage of the all solid-state design. Diode-pumped Nd:YLF lasers exhibit superior energy reproducibility and beam-pointing stability, and the TEM00 beam profile with ~100 kW peak power is an ideal combination for minimizing optical damage. As longtime DPSS laser users are aware, the evolution of the technology has brought with it a dramatic increase in laser diode lifetimes, routinely 10,000 hours before the Nd:YLF output slips below specified performance levels.

Other factors, too, contribute to reliability of the all-solid-state design. Intra-cavity doubling in an LBO crystal assures a green (527 nm) output with excellent long-term stability; the short-cavity, high-gain design of the Ti:sapphire oscillator does not require injection-seeding or intracavity etalons for single-mode operation; and, compared to flashlamp-pumped Nd:YAG lasers, diode-pumped lasers provide a very real added advantage in their absolutely hands-off reliability (see Fig. 2). This degree of stability and reproducibility in a pump laser makes it possible to design Indigo systems into industrial environments where even occasional tweaking is not really an option.

In the future, an Indigo system operating at either 248 or 193 nm may also be applied in seeding large-frame KrF or ArF excimer lasers as narrow bandwidth and precise frequency control become increasingly more critical within lithography. On the wish list of stepper and scanner suppliers is an excimer laser that can change wavelengths on the flyas can be accommodated by alternate seeding of an excimer with two Indigo systems pumped by a single DPSS Evolution X with more than 10 W output at 527 nm. By exposing photoresist with two different wavelengths (two scans in succession), the effects of interference are reduced and the subsequent detail is enhanced.

REFERENCE

- Ko et al., Opt. Lett. 20(7),70 (1 April, 1995).

JEREMY WESTON is founder and president and RON OLSON is cofounder and marketing consultant at Positive Light, 101 Cooper Ct., Los Gatos, CA 95030; e-mail: [email protected] and [email protected].