Semiconductor Lasers 2000: The early years: promise and problems

This month contributing editor Stephen J. Matthews begins a series of tutorial-style articles that trace the development of this enabling invention from the earliest infrared devices, which produced only a few milliwatts of output power and suffered from marked astigmatism and poor noise, to the newest high-power arrays for applications still in R&D labs. -Ed.

On a park bench in 1951, Charles Townes jotted down on the back of an envelope the essentials for the precursor to the first laser. In the words of his brother-in-law Arthur Schawlow, “ . . . (we) were surprised at how easy it turned out to be. We had assumed that . . . it must be very difficult. But once you knew how, it was not at all difficult.”

Gas and solid-state laser technology has always retained the spirit of making something new in the laboratory. It is an eclectic assortment of knowledge and skills—working with high voltage, “walking” a resonator, and so on. With a few exceptions, these lasers are assembled on bench tops for use by technologists.

But from the standpoint of the laser that has had the greatest impact on society—the diode laser—the technology today has changed entirely. Making a laser is much more complicated—fabricating quantum wire lasers is not an “easy” technology, but the most common applications of the laser are much more familiar—everyone knows how to make a phone call or buy groceries.

Schawlow and Townes did not anticipate that children would be able to play with a pocket laser produced by the millions in a half-billion-dollar facility. From delicate, low-power devices with poor beam quality limited to infrared (IR) wavelengths, diode lasers have evolved to become so widely used that production this year is expected to surpass 400 million units.

Sparkling in the background

Following development of the ruby laser in 1960, it did not take long for work to start on a semiconductor laser. The potential of the technology for optical communications was recognized immediately. Having this goal at the beginning led researchers to techniques and designs that are the underpinnings for much of the current technology.

Gallium arsenide (GaAs) diodes were investigated during World War II, and physicists had long noticed that the p-n junction of a GaAs diode sparkled with a deep red light when forward biased. By the early 1960s, the GaAs LED was a familiar device to researchers.

When the p-n junction of a semiconductor diode is forward-biased, electrons from the n-doped region and holes from the p-doped region accelerate to the junction, where they recombine and release energy. Both energy and momentum must be conserved in this recombination. The energies and momenta of the holes and electrons before any bias voltage is applied (that is, when in equilibrium) are properties of the material.

More light, less heat

In indirect-bandgap materials, such as silicon, the momenta of the electrons and holes do not match in equilibrium, and an electron must lose momentum to the crystal lattice to recombine with a hole. For these materials, the energy from electron-hole recombination goes into heating the crystal. Hence, diode lasers are not made from silicon.

For direct-bandgap materials, electrons moving in the n-layer and holes moving in the p-layer have, on average, the same momentum when in equilibrium. Direct-bandgap semiconductors release the energy from electron-hole recombination as photons, with a wavelength corresponding approximately to the bandgap energy of the material. This is the basic principle of the LED.

Gallium arsenide is a direct-bandgap material. When semiconductor lasers were suggested by Nikolai Basov in the Soviet Union and by others, it seemed that a GaAs LED was a good place to start. The semiconductor industry did not exist in the early 1960s, and the initial challenge was producing high-grade GaAs crystals.

From darkness, light

Robert Hall and his group at General Electric (Schenectady, NY) published the first report of laser action in a semiconductor in September 1962, and groups at IBM (Yorktown Heights, NY) and the Massachusetts Institute of Technology (Cambridge, MA), which had started work before Hall, reported success within weeks of his results. Soon after, researchers reported lasing in a variety of materials, all with wavelengths in the near-IR.

For an LED to become a laser, it needs to have a population inversion and optical feedback to allow the photons generated by recombination to stimulate more electron-hole recombination. Optical feedback was provided by simply cleaving the facets of the crystal that are perpendicular to the plane of the p-n junction. The high index of refraction of the semiconductor resulted in 30% or so of the output reflecting back into the junction layer.

Population inversion was achieved through high levels of doping and by turning up the current. In those early days, "turning up the current" meant turning it up high. The threshold current for those first devices was typically greater than 10,000 A/cm2, and with operating currents as high as 100 A there were problems with heat. Even pulsed at duty cycles of less than 0.1% and cooled to 77 K, device lifetimes were measured in seconds.

High current and heat were not the only problems. The output facets were easily and catastrophically damaged by the electric fields in the beam. More-gradual but still-fatal failures were traced to defects in the crystal lattice, especially in the junction region. It seemed that the lasing process itself contributed to these failures, because electron-hole recombination always produces some nonradiative energy that heats the defects in the crystal.

A flash in the pan?

The first reports of success spurred feverish efforts to improve the lasers. Dielectric coatings on facets and improved drive circuitry reduced the rate of catastrophic failure. Fabrication techniques developed to reduce lattice defects were to pay major dividends in future developments.

Early devices were fabricated by diffusing n and p dopants directly into each side of the compound. As a result, the junction layer was prone to a high number of defects and was not optimally flat. To address this, researchers borrowed a method of growing crystals known as liquid-phase epitaxy. The n-doped GaAs was polished and dipped into molten p-doped GaAs, which solidified to form a single crystal. This fabrication method lowered operating currents to about 10 A.

Reducing the current further, however, proved to be difficult, and some of the euphoria waned. In fact, ten years passed after the first demonstration of a diode laser before a room-temperature CW device was commercially available, and it was 20 years before diode lasers found widespread commercial application.

Paradoxically, the breakthrough came by limiting the size of the gain region. The early diodes used a homostructure design—that is, these diodes were made entirely from the same compound with a single p-n junction. It turned out that a high threshold current is a fundamental limitation of this design.

Particles check in and don't check out

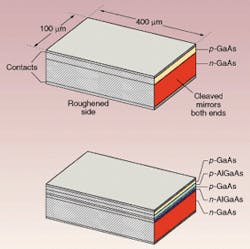

Homostructures do a poor job of confining both light and electrons in the junction region, and lasing threshold is difficult to attain. It was found that layers of different compounds—a heterostructure—can improve confinement in the junction. Using liquid-phase epitaxy, double-heterostructure diodes were made from layers of p-type and n-type gallium aluminum arsenide (GaAlAs) sandwiched around a layer of GaAs.

The GaAlAs layers have a larger energy gap than the central GaAs layer and so provide a potential well that is easy for the charge carriers to fall into and difficult to escape from. In addition, the GaAs layer has a higher index of refraction than the GaAlAs layers and so confines photons in the central layer through total internal reflection. The heterostructure design allows the volume of the material in which laser action takes place to be specified by the thickness of the central region and not directly by its material properties.

The first diode lasers to use this principle were single-heterostructure devices (think of an open-faced sandwich). This design reduced the threshold current sufficiently to allow room-temperature pulsed operation.

In 1970, researchers at the Ioffe Institute in Leningrad, Russia, made the first double-heterostructure laser and achieved CW operation at room temperature. Their success was followed almost immediately by a nearly identical but independently conceived design from Bell Labs (Murray Hill, NJ). The double heterostructure became the basic framework for all future development (see figure).

Themes both old and new

This began a major theme in the history of diode-laser technology—the application of fabrication techniques (often developed by the semiconductor industry) to control diode output and improve reliability. Increasingly exotic structures based on the double heterostructure, such as the dual-channel planar buried heterostructure (DCPBH), proliferated in bewildering variety. The improvements have been startling—the DCPBH, a mainstay of optical communications, operates at about 10 mA.

Early in their history, lasers in general were described as a solution in search of a problem. It seemed that almost any material could lase (including vapors from scotch whiskey), but the laser output was largely unpredictable, and finding an application was hit-and-miss. For diode lasers, the reverse has been true.

A clear view of the potential applications for diode lasers has guided the systematic development of specific outputs. The use of GaAlAs to form the first heterostructures points out another major theme that has continued from this early development—tailoring the laser output through variations in the chemistry of the alloys.

Only the beginning

Will all lasers eventually be replaced by diode lasers, the way that vacuum tubes were replaced by transistors? In practical terms of the total laser marketplace, this question has already been settled—diode lasers account for more than 99.95% of all lasers produced annually.

To be sure, nondiode lasers still account for one-third of the laser market in revenue. It is, however, entirely possible that diode lasers will eventually replace almost every other type of laser in almost every other type of application. The only mass-market success ever attained by either gas or solid-state lasers, barcode scanning, has been usurped by diode lasers. Certainly, for the people working in the gas and solid-state laser industry, the question of which laser in what application will be replaced next is crucial. But, as for the transistor, the larger question is this: in what new and unexpected directions will this technology take us?

Following the invention of the double heterostructure, many problems still confronted developers, notably poor beam quality and inferior frequency characteristics. The application driving the original invention, optical communication, was still years away. What was needed to sustain the development effort was, in the parlance of PC marketing, a “killer app”—a success in the mass market. This was to come from an unexpected source—the entertainment industry.

Next month this series will discuss how semiconductor lasers moved from the lab to the home.

About the Author

Stephen J. Matthews

Contributing Editor

Stephen J. Matthews was a Contributing Editor for Laser Focus World.