Novel package doubles output

LIGHT-EMITTING DIODES

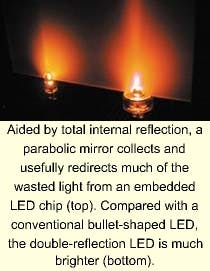

KYOTOOmron Corp. has developed a new packaging technology that at least doubles the brightness of a light-emitting diode (LED). Called double-reflection LED (DR-LED), the package efficiently sends emitted light in the forward direction.

Conventional LEDs consist of a chip housed within a plastic package. There are many types of packages, but one popular design is shaped like a bullet. The front part of the bullet-shaped package serves as a lens to send the light forward. However, light is sent out in all directions from the LED chip, and the lens can collect only a fraction of that light, with the rest of the light going to waste.

New design

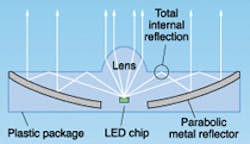

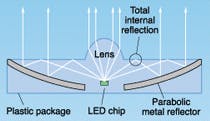

Omron has proposed a new design (see figure). Light sent out from the chip in the forward direction is collected by the lens-shaped part of the package. Light going off in a diagonal directionheretofore wastedis totally internally reflected by the top part of the package, then re-reflected in the forward direction by a parabolic metallic mirror.

Although this is an extremely simple design, a red LED with a directivity angle of 10° has been shown to achieve 2.5 times the brightness of a conventional red LED. Production costs should not be much higher than for conventional packaging. This development shows that to make brighter LEDs, it is not only necessary to improve chip technology; mounting technology is also crucial.

The method can increase apparent emission area, so it is especially useful for applications that require many densely packed LEDs, such as car lamps and traffic signals. Because the brightness of each LED increases, the number of LEDs required should decrease; therefore, the total cost of the lamp should go down.

Courtesy O plus E magazine, Tokyo