Ultrafast Lasers: Picosecond lasers perform subsurface marking of stainless steel medical devices

There is a growing need to apply permanent marks to stainless steel medical devices, and the marks must meet several strict criteria that largely preclude the use of non-laser marking techniques such as printing or engraving. A relatively new laser-based process—subsurface black marking using a picosecond laser—meets the stringent marking demands of medical device manufacturers.

The benefits of permanent identifying marks on medical devices encompass counterfeit prevention, product traceability, long-term quality control, return fraud prevention, and distribution regulation. More importantly, medical device marking is becoming increasingly mandatory for the U.S. market under new FDA regulations. For reusable, nonimplantable devices, a critical date is September 24, 2018. After that date, "a class II device that is required to be labeled with a UDI must bear a UDI as a permanent marking on the device itself if the device is a device intended to be used more than once and intended to be reprocessed before each use" as required by § 801.45.1 This regulation thus encompasses one-time and multi-use stainless steel tools and devices where "reprocessing" typically refers to autoclaving.

Marking and passivation

Most commonly used stainless steel alloys for medical devices have a natural passivation outer surface of chromium oxide that prevents corrosion during repeated autoclaving. This passivation can be compromised by machining, grinding, polishing, or other mechanical processes during device fabrication. Repassivation with a citric or nitric acid solution removes the culprit (unoxidized) iron particles from the outer surface layer.

The challenge for medical devices is to find a marking process that satisfies several key criteria. First, it must have high contrast so that it can be discerned by a range of different means. Second, it must be permanent, which in this case means that it must not fade because of regular handling and use, or because of any subsequent repassivation and repeated autoclaving. Third, the mark should be subsurface, having no surface relief that could harbor contamination or cause irritation/inflammation during use. Fourth, the mark should be applicable to contoured surfaces. Fifth, the marking process in itself should not create the need for additional passivation. And lastly, the entire process should be automated and cost-effective. Using picosecond laser pulses to create black subsurface marks now appears to meet every one of these key criteria.

Limitations of traditional laser marking

There are several well-established approaches to laser marking, and numerous industries have used these techniques for decades. Carbon dioxide (CO2) lasers, nanosecond-pulsewidth diode-pumped solid-state (DPSS) lasers, and continuous-wave fiber lasers are widely used for this purpose, depending on the particular material involved. These diverse laser-marking applications involve producing a change inside the bulk of the material, a color change on a surface, or a macroscopic change in surface relief (for example, engraving) or texture that is easily visible. Some of these processes are the marking method of choice in other sectors of the medical market, such as pharmaceuticals.

For stainless steel medical devices, however, the problem is that these established laser processes all create marks via a photothermal process. In short, a tightly focused laser beam delivers intense heat in a highly localized manner, raising the material temperature to produce some type of change. For example, a CO2 laser marks various substrates by actually melting and boiling off material to create surface relief.

Some of these lasers have already been investigated for "permanent" marking of stainless medical devices with varying degrees of success. To date, the best results had been delivered using near-infrared (near-IR) output from fiber lasers or DPSS nanosecond lasers to produce black marks. These marks generally exhibit high contrast. However, the black appearance is due primarily to the creation of an outer layer of oxide—the laser pulses cumulatively heat the metal to the point at which it reacts with oxygen in the ambient air. This oxidation compromises the corrosion resistance of the surface, so an additional repassivation step is unavoidable after this type of marking. However, passivation typically causes this type of mark to fade. For multi-use products, a major limitation is that these oxide marks also fade with repeated autoclaving. As a result, the contrast eventually passes below threshold for certain automated readers.

Picosecond laser marking

With picosecond lasers, the pulse duration is typically shorter than the time for heat to flow out of the laser interaction zone, even in metals, so peripheral thermal effects are greatly reduced compared to nanosecond lasers. This means that a much higher portion of the total laser power is used to remove material, rather than produce unwanted heating. Second, the high peak power of picosecond pulses enables unique interactions between the laser and the substrate, including multiphoton absorption, where material is directly atomized in a relatively cold process, rather than heated to vaporization via boiling.

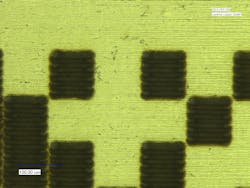

Picosecond lasers are already being used to directly mark automotive metal parts with 2D barcodes (see Fig. 1) where it is essential that the barcode not fade with usage. They are also used in marking the aluminum cases of tablet computers and other compact handheld electronic devices, as well as marking the sapphire wafers used in the production of high-brightness LEDs (a notoriously hard material to mark). Given the limitations of marking stainless steel medical devices with longer-pulse lasers, both laser tools builders and some early adopters in the medical device industry have recently investigated using picosecond lasers for this purpose.

At Coherent | Rofin, we have been working on optimizing stainless steel marking with our Rapid NX picosecond laser, which is a mode-locked DPSS laser with a neodymium vanadate (Nd:YVO4) gain medium. This laser has an average power of 7 W, a pulsewidth <15 ps, and a maximum pulse repetition rate of 1 MHz. Figure 2 shows typical marks created on 1.4301 stainless steel with this laser. While these marks appear similar to the black marks produced using nanosecond lasers, microscopic investigation reveals that their actual structure is quite different. The black appearance of nanosecond-laser marks on steel primarily arises from the creation of a black oxide. With picosecond laser marking, a major contributor to the high-contrast black appearance seems to be a subsurface nanostructural change that results in efficient light trapping and light absorption, without significant change in the material composition. (Microstructured surfaces that suppress reflections are not new—in fact, they're the basis of the radar-evading stealth technology used in military aircraft.)

More important than the nature of the marks, there is a significant difference in performance for the black marks produced using a picosecond laser vs. a nanosecond laser. First, our tests show that the marks are naturally resistant to corrosion (rusting) during repeated autoclaving, and do not require any repassivation for this purpose. And second, neither passivation nor autoclaving cause any appreciable fading of these marks. This extends the lifetime of reusable devices, lowering the cost of ownership. It also simplifies and lowers the overall cost of medical device fabrication, as it puts no restriction on the sequence in which marking and passivation processes are performed during production. Thus, picosecond laser marks are more permanent and less restrictive to use than nanosecond laser marks.

Practical advances in picosecond marking technology

While the cost and complexity of traditional picosecond lasers and tools meant that only high-value products could justify their usage, a new generation of picosecond lasers, built using advanced materials and methods, is now available at a lower cost than before.

Laser design and development following highly accelerated life testing/highly accelerated stress screen (HALT/HASS) principles drives the comprehensive testing of laser products before shipping to find any weaknesses because of assembly, workmanship, and so on. To support both integrators and end users, the Coherent Rapid NX picosecond lasers are supplied at four different vertical points in the market: standalone lasers, marking subsystems (see Fig. 3), complete workstations, and turnkey workstations with preoptimized software recipes.

REFERENCE

1. See https://goo.gl/znEp9L.

About the Author

Thorsten Ferbach

Thorsten Ferbach is a business development manager at Coherent.

Frank Gaebler

Director of Product Marketing, Coherent LaserSystems GmbH & Co KG

Frank Gaebler is director of product marketing at Coherent LaserSystems GmbH & Co KG (Lübeck, Germany).