Scientific Lasers: Optothermoelectric nanotweezers improve particle-trapping efficiency

A collaborative effort between researchers at The University of Texas at Austin and Pennsylvania State University (University Park, PA) and researchers in Spain, Los Angeles, and Turkey, the development of optothermoelectric nanotweezers powered by simple optics, with a tunable working wavelength and low power consumption, promises multiple innovations in nanophotonics and colloidal particle science.1

Most optical tweezers require high laser power (tens to hundreds of milliwatts) to manipulate metal nanoparticles, potentially damaging any surface molecules or even the metal particles themselves. Furthermore, localized surface plasmons excited by the trapping laser source can cause increased absorption and subsequent particle heating and light scattering, all increasing trapping instability.

Conversely, optothermoelectric nanotweezers (OTENTs) take advantage of this heating (a photothermal effect called Joule loss) by separating the ionic species around the heating source and creating a “thermoelectric field” that guides metal nanoparticles to the trapping site with low-power laser sources at single-particle resolution.

Thermoplasmonics, surfactants, and heating

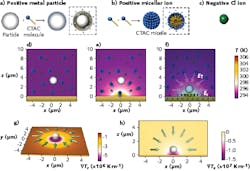

To facilitate particle manipulation via OTENT, the colloidal metal nanoparticles are supplemented by a cationic surfactant called cetyltrimethylammonium chloride (CTAC) that adsorbs on the metal nanoparticle surface and generates a thermoelectric field upon laser heating by a 0.216 mW, 532 nm laser (with 2 µm spot size). The solution is contacted by a porous gold film to create a solution/substrate interface that, when irradiated with the laser, causes localized optical heating for low-power particle trapping—unlike most optical tweezers that trap particles through the gradient forces generated by a higher-power laser (see figure).

More specifically, laser radiation of the thermoplasmonic substrate causes the CTAC micelles and chlorine ions to migrate from a hot to a cold region, generating an electric field that then draws the metal nanoparticles into the laser beam spot with a trapping electric field estimated to be between 50 and 300 V/m.

Localized particle trapping through laser heating was experimentally demonstrated for gold and silver nanospheres using 532 nm laser power levels of 0.05 to 0.04 mW/µm2—roughly two to three orders of magnitude lower than typical laser intensity levels used for conventional optical tweezers.

Experiments also included in situ optical spectroscopy and parallel and multiple-particle trapping. With this technique, researchers can see and identify the trapped particles based on their intrinsic optical response, which can also be precisely tuned through controlling the multiple-particle coupling inside the trap. OTENT allows the manipulation and analysis of metal nanoparticles as small as 20 nm in diameter.

“OTENT provides the possibility to precisely control nanosized objects with very low-power laser beams, which is challenging for previous optical techniques,” says Yuebing Zheng, an assistant professor at UT-Austin who leads the project. “Optical control of low-dimensional materials in a noninvasive way is very important. As one of our next steps, we will employ OTENT to assemble functional optical devices using colloidal nanoparticles as building blocks. We will also improve biocompatibility of this platform for manipulation of living cells and biomolecules in order to advance cellular biology, early disease diagnostics, and intracellular drug delivery.”

REFERENCE

1. L. Lin et al., Nat. Photonics, 12, 4, 195–201 (Apr. 2018).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.