Sunlight and nanostructured hydrogel purifies and desalinates water

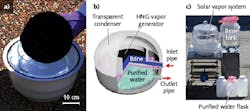

Recognizing that evaporation and condensation (distillation) to produce purified water is typically a slow and extremely inefficient process that needs significant industrial infrastructure and system costs, researchers at the University of Texas at Austin have developed a solar vapor generator from a novel hydrogel material that uses natural sunlight to efficiently produce purified and desalinated water.

The hierarchically nanostructured gel (HNG), or hydrogel skeleton, is fabricated from a hybrid of polyvinyl alcohol (PVA) and polypyrrole (PPy), creating a molecular mesh that facilitates water evaporation when exposed to natural sunlight. A patent has been filed for the process, which not only removes impurities, but also naturally removes salt and could be engineered to remove other targeted pollutants.

In one experiment, a solar-powered HNG sample floating on a large volume of brine water was able to evaporate water at a record-high rate of 3.2 kg/m2 per hour using 94% solar energy from 1 sun irradiation, producing 18–23 liters of water per square meter of the HNG material. The PVA hydrogel (water-soluble polymer) acts as a skeleton that has good mechanical properties to support the whole structure, while the PPy serves as an effective light absorber to convert solar energy to heat. The as-obtained gel is black in color, flexible, and elastic. Reference: F. Zhao et al., Nature Nanotechnol. online, doi:10.1038/s41565-018-0097-z (Apr. 2, 2018).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.