Higher and higher

Diode-pumped neodymium lasers exhibit superior energy efficiency, reliability, stability, and beam quality. Second-harmonic generation (SHG) now routinely extends these benefits to applications at visible wavelengths. Converting the fundamental output to still higher harmonics brings the same benefits to applications in the ultraviolet (UV) spectrum.

The commercial success of SHG has encouraged development of systems using third-harmonic generation (THG). The market for lasers that use SHG is primarily scientific—these lasers typically pump other lasers, often in wavelength-tunable systems. While the THG market also has a scientific segment, the major applications for THG systems make direct use of the UV output.

A variety of applications

Sources of coherent UV radiation are needed in applications such as chemical sensing, writing fiber Bragg gratings, and in many forms of materials processing. The military is using ultraviolet lasers in the development of new fluorescence sensors for biological-agent detection and decontamination. Other military applications under development include free-space, short-range optical communications. These signals are difficult to intercept, and would be particularly useful in urban settings, where UV can easily scatter around buildings.

The processing of ceramics, glasses, and polymers, along with some specialized processing of metals, all benefit from the use of UV laser sources. Third-harmonic systems using solid-state lasers can deliver diffraction-limited beams with excellent pulse-to-pulse stability at high peak powers. This combination of features is very desirable for precision cutting and drilling.

In ceramics, the shallow absorption depth for UV and the high energy density on the surface combine to vaporize the material, with little heat transfer into the solid. This low thermal stress produces a cut free of cracks, allowing the fabrication of micron-sized structures. In metals, however, vaporization produces a plasma above the cut that acts to shield the surface from the beam.

This shielding becomes the limiting factor in drilling high-aspect-ratio holes in steel. To reach the bottom of the hole, the laser beam must penetrate a thick plasma (the plasma layer at a flat surface remains only about 100 µm thick). It happens that shorter wavelengths produce less plasma, so UV beams reduce the shielding and improve drilling efficiency.

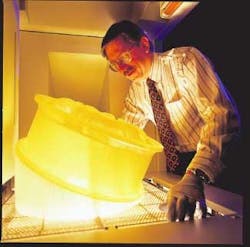

Solid-state UV lasers are used in stereolithography systems to create three-dimensional models in a matter of hours (see Fig. 1). The laser, interfaced with a CAD/CAM system, traces a cross section of the model layer by layer across the top of a vat of epoxy resin. The epoxy hardens in a layer 0.025 to 0.25 mm thick. After each layer is traced, the model is lowered slightly into the vat to trace the next cross section, reiterating this process until the model is formed.

Sum frequency mixing

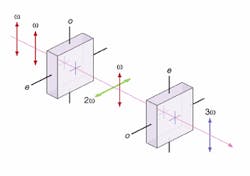

While it is theoretically possible to accomplish THG directly by frequency-tripling a fundamental beam in a single NLO crystal, in practice THG is produced indirectly. The fundamental beam is first frequency-doubled. This second-harmonic beam is combined with the unconverted remnant of the fundamental beam in a separate crystal (see Fig. 2). The THG output results from nonlinear "sum frequency mixing."

Much of the development for sum frequency mixing is based on experience gained at the National Ignition Facility (NIF) at Lawrence Livermore National Laboratory (Livermore, CA). The most effective wavelengths for inertial confinement fusion lie near 300 nm, whereas the neodymium-glass NIF laser has its output near 1.05 µm, so THG is crucial to its mission. The basic NIF design uses two KDP (potassium dihydrogen phosphate) crystals, the first for SHG and the second crystal for sum frequency mixing.

Second-harmonic generation itself can be thought of as a special case of frequency mixing, in which both input beams are identical. In the more general case, a beam of frequency ω1 combines with a second beam of frequency ω2 through the second-order susceptibility of a nonlinear crystal to produce a new beam of frequency ω3. When ω2 = 2ω1, then ω3 = 2ω1 + ω1 = 3ω1, and the output is the third harmonic of the fundamental.

Why mixing is preferred

In contrast, frequency tripling is a third-order effect in which one fundamental beam (the equivalent of three beams at ω1) produces in a single crystal a new beam at ω3. The problem arises from the requirement that the fundamental beam and the tripled beam stay in phase in the crystal—that is, they must be phase-matched. In the quantum picture, phase-matching is equivalent to satisfying the conservation of momentum for the three photons that are converted into one photon with three times the individual energy.

As it turns out, the efficiency of THG in an infinite, uniform nonlinear medium is zero, even with perfect phase-matching. This is also the case for most practical nonlinear materials. The frequency-tripled waves generated in different regions of the crystal interfere destructively, resulting in net zero THG.

Although frequency-tripling is not a practical route to THG, tripling can take place directly in a non-isotropic medium (see Fig. 3). Unlike second-order nonlinear coefficients, which vanish in some materials because of crystalline symmetry, all materials possess a third-order coefficient. Third-order phenomena span a wide range of interesting, useful, and sometimes even bizarre optical effects.

A difficult goal

In practice then, the same second-order nonlinear process used for SHG is also used for THG via sum frequency mixing. This is true for commercial systems that produce fourth- and fifth-harmonic output as well. A fundamental beam is first frequency doubled, then either doubled again to obtain the fourth harmonic, or sum frequency mixed for THG, which is then mixed with the SHG beam to produce the fifth harmonic. Producing these harmonics directly is extremely difficult, because the infrared (IR) fundamental has to phase-match with the UV output.

Solid-state continuous-wave (CW) systems have low output fluences, so they require an external resonant cavity to obtain reasonable nonlinear conversion levels (intracavity conversion beyond SHG has the UV-IR phase-matching problem). It is more typical to take advantage of the high peak powers of Q-switched or modelocked lasers to obtain good conversion efficiency. Gigawatt peak powers (10 mJ pulses with a duration of 10 ns) with good beam quality can be converted with 30% efficiency to the third harmonic and 10% efficiency to the fourth harmonic. This results in average powers of up to 10 W for wavelengths near 355 nm, and about 1 W around 266 nm.

Despite their complexity, systems using higher harmonics nevertheless take aim at already existing and potentially lucrative markets for deep-UV laser sources. Krypton and argon fluoride (KrF and ArF) excimer lasers operating at 248 and 193 nm, respectively, are widely used for chip fabrication in photolithographic production tools. The manufacture of these tools itself requires excimer lasers for their alignment. But excimer lasers have drawbacks, including size and utility requirements.

Harmonic output around 266 nm is readily achieved by doubling in a resonant external cavity the output of a standard intracavity doubled neodymium laser. But ever-decreasing lithographic dimensions will require lasers at shorter wavelengths. Excimer lasers at 157 nm have been under development for some time. Matching this performance with the harmonic output of a solid-state system is a formidable challenge.

The difficulties are with the nonlinear materials. The best materials are borate compounds such as cesium lithium borate (CLBO) and beta-barium borate (BBO), which are transparent below 200 nm but cannot perform phase-matching in that spectrum. Conventional wisdom says it takes 10 years and $10 million to develop a practical new nonlinear crystal. In this case, that estimate may be conservative.

Next month: Optical parametric oscillators and amplifiers.