OPTICAL INTERCONNECTS: VCSELs send data over optical links

Vertical-cavity surface-emitting lasers (VCSELs) are moving out of the laboratory toward real commercial products, and parallel optical interconnects may be one of the first places in which they are found. These multifiber links are designed to allow a minimum data rate of about 400 Mbit/s per line for networking of high-end servers in video and multimedia or telecommunication switching networks. The key enabling technology for these applications is the VCSEL.

Anis Husain, a program manager at the Advanced Research Projects Agency (ARPA), touts VCSELs as revolutionary. "I believe their effect upon the optoelectronics field will be similar to the effect that CMOS technology had on silicon-based electronics," said Husain. While fiberoptics technology has been widely used for longer-distance networks, the cost of shorter-distance links has not been competitive with copper-based solutions, despite the performance advantage. "VCSELs will allow high-speed fiberoptic communication networks to become cost-effective for distances of less than 100 meters," he said.

Motorola Logic IC Division (Chandler, AZ), Honeywell Technology Center (Bloomington, MN), Hewlett-Packard (Palo Alto, CA), and Vixel Corp. (Broomfield, CO) are among the companies actively developing VCSEL technology. Some development monies are coming from ARPA and other government sponsors, but Motorola, for one, has decided to develop VCSEL and other optical-link technologies with internal funds.

Structural advantages

VCSELs are fabricated on gallium arsenide (GaAs) wafers and are designed to emit optical energy perpendicular to the wafer surface. Successive deposition layers form the active region as well as the top and bottom mirrors in a vertical stack. When voltage is applied, laser light is emitted along the wafer surface normal. The output-energy pattern is circular, allowing more efficient coupling to fiberoptic devices. Linear and area arrays of VCSELs can be fabricated in this manner.

Because the p and n contacts are on the same side of the wafer, VCSELs can be probe tested at the wafer level. Conventional edge-emitting GaAs lasers must first be separated from the wafer and packaged with the edge positioned in the desired direction of light output before they can be tested. Although edge-emitting diode lasers, which are made in high volumes (primarily in Japan) for use in CD-ROMs, can be used in optical interconnect cables, VCSELs can be packaged with higher density and more cheaply, thereby lowering a significant cost barrier.

In addition, VCSELs have the potential to significantly impact the power consumption in complex electronic I/O circuits. Because much power is consumed with silicon-based I/O circuits, very-low-threshold VCSELs could reduce power consumption by using optical interconnects. Motorola senior applications engineer Jerry Grula commented, "The VCSELs we are developing for our 10-channel optical link have threshold currents in the 1–2-mA range. Edge emitters typically have more than a 25-mA threshold." But researchers at the University of Southern California (Los Angeles) and the University of Texas (Austin), for example, have demonstrated thresholds in the tens-of-microamps range, paving the way for extremely low-power operation.

Grula reported that, from a manufacturing standpoint, yields and uniformity of the VCSELS have been very good. In addition, they seem to be relatively insensitive to temperature variations, allowing the elimination of thermo-electric coolers or optical-feedback mechanisms. "The whole idea is to fabricate VCSELs in a high-volume, low-cost environment. Cost is critical to the success of optical interconnects," said Grula.

ARPA's Husain echoed this sentiment. "Our data show that customers want high-speed, short-distance optical interconnects, but that they don't want to pay more than they do for a copper solution."

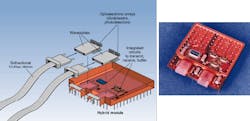

Motorola has allowed potential users to evaluate its optical data link, Optobus, for about six months (see figure). The design will soon be finalized, and it will be put through a rigorous qualification program leading to a product introduction. No one yet knows if VCSELs will have the necessary long-term reliability, because there is so little information on VCSELs.

"We are shooting for a 15–20-year VCSEL life, defined as the reduction in light output of 3 dB," said Grula. "So far, extrapolated data suggest that the VCSELs are as good, if not better, than edge emitters. We anticipate the final results from our qualification program will be available in about six months," concluded Grula.

About the Author

Chris Chinnock

Chris Chinnock is president and owner of Insight Media in Norwalk, CT. He is a 30-year display industry veteran with experiences in displays, broadcast, cinema, ProAV, and consumer electronics.