The announcement of the gallium nitride (GaN) blue diode laser by Nichia Industries (Anan, Japan) in 1999 perhaps drew as much attention inside and outside of the industry as any development since the invention of the laser itself. But expectations for full production were unreasonably high, and commercialization has been slowed by a barrage of litigation between the two major competitors in this technology, Nichia and Cree Inc. (Research Triangle Park, NC).

Battle over blue

Nevertheless, last year both Nichia and Cree announced major technical and product developments. Nichia plans a release of a single transverse-mode, 30-mW laser operating at 408 nm in the first quarter of this year, and has reported experimental results of 2 mW at 369 nm.1 Cree claims lifetimes in excess of 1000 hours at 3 mW for its 405-nm device. According to Norbert Hiler, vice president of optoelectronics at Cree, the company began sampling these lasers at the end of 2001.

Clearly, these devices are in every sense years away from the million-hour lifetimes of the diodes used in CD-ROMs. It took the combined efforts of some of the world's leading corporations for red diode lasers to reach this level of reliability, but the potential that motivated this effort is much the same today for blue lasers.

The data density written to storage disks increases inversely as the square of wavelength of the optical stylus. Together with other improvements, the use of blue lasers for next-generation DVD will result in storage capacity of more than 15 Gbytes per double-sided disk, 20 times that of a CD-ROM (see photo at top of this page). According to Strategies Unlimited (Mountain View, CA), the blue diode-laser market for optical storage alone is expected to exceed $2 billion within five years.

In general, the obstacles to greater reliability are the same as they were for early diode lasers—overcoming the results of the mismatch in the crystalline lattices of the alloys that are grown in layers to make the device. Lattice mismatches cause a variety of defects that result in heat, rather than light, from electron-hole recombination, and lead to catastrophic device failure.

Tough enough?

The hardness of GaN contributes significantly to its success as a laser, inhibiting the spread of defects away from their origin as happens in less robust materials. The defects themselves appear less likely to create nonradiative transitions in nitrides than in other semiconductors. However, the GaN lattice does not match well to any common substrate material, and so a very high defect density is the norm.

Nichia relies on the innovative metal-organic chemical-vapor deposition (MOCVD) techniques perfected by Shuji Nakamura that overcame problems with p-type doping of GaN and allowed GaN growth on sapphire substrates. Cree's technology relies on substrates of silicon carbide (SiC), which has the advantage of a high thermal conductivity. Both SiC and sapphire are resistant to common integrated circuit (IC) fabrication techniques and are difficult to process. For this and other reasons, Nichia has been experimenting with varieties of GaN substrates.

While heavily focused on each other, Nichia and Cree may find surprises in their periphery. The Industrial Technology Research Institute of Taiwan (Hsin Chu) announced recently that it had successfully developed a GaN diode laser of its own design, specifically for DVD applications.

True blue

The light from all of these lasers is closer to ultraviolet than blue, and not useful for the applications of a true blue diode laser. The possibilities for miniature full-color projection displays, for example, seem beyond prediction. However, eye sensitivity at 400 nm is only 0.3% of its maximum sensitivity at 555 nm, so it is imperative that the laser wavelength be lengthened for such applications.

Indium is added to the nitride alloy to lower the bandgap (corresponding to 350 nm for pure GaN), but there is a point beyond which adding more indium to further lengthen the wavelength causes unacceptable loss of efficiency and decreased reliability. For unknown reasons, the indium seems to leave the alloy and clump in an uneven distribution. Nevertheless, progress is being made in this area through painstaking control of the fabrication process.

Last year, Nichia offered samples of 440-nm lasers at a unit price of $3000. The laser features an operating current of 55 mA and has an estimated lifetime of 500 hours. Nichia has also reported on laboratory results for a laser at 465 nm, and states that its long-term goal in this area is to achieve operation at 510 nm. These announcements are a change in course for the formerly secretive company, which for the first time this year will be represented at major trade exhibitions. (Note: Nichia demonstrated a 470-nm diode laser at the Photonics West [San Jose, CA] trade show in January.)

Short, wide, and handsome

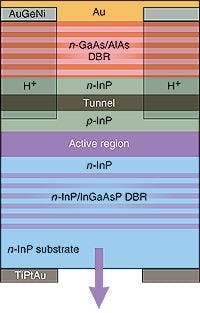

At the other end of the spectrum, the makers of vertical-cavity surface-emitting lasers (VCSELs) are also seeking longer wavelengths. Now well-established at 850 nm and the laser of choice for short-distance optical networks, VCSELs are manufactured in large inexpensive arrays of individual elements, each producing a nice circular beam that simplifies the fiber interface. Their vertical geometry results in short cavities with fast dynamic response and very low threshold currents.

The benefits of VCSELs would best be put to use if applied to wavelength-division multiplexing (WDM) for longer distances and higher-density networks. To do so, they must operate around 1330 and 1550 nm, where silica optical fibers have lowest dispersion and loss. Achieving operation at the longer wavelengths has proven troublesome due to material difficulties in growing the Bragg reflectors that act as cavity mirrors.

The small cavity of a VCSEL produces low gain, so the Bragg grating mirrors must have low loss and high reflectivity. In addition, they must have good thermal conductivity to accommodate the heat load of the active laser region, and should be electrically conducting as well, since carrier injection ideally takes place through this cavity dimension. Matching the lattice size of the grating material to the lattice of the substrate and of the active region is also critical.

Bonding

Vertical-cavity surface-emitting lasers at 850 nm are made from alloys of gallium arsenide (GaAs), and the epitaxial growth of alternating layers of GaAs and aluminum gallium arsenide (AlGaAs) produces Bragg reflectors of sufficiently high quality. But commercial lasers at longer wavelengths are based on alloys of indium phosphide (InP) and similar materials. These alloys produce poor-quality Bragg reflectors.

About 10 years ago researchers at the University of California-Santa Barbara developed a wafer-bonding technique that allowed high-quality Bragg reflectors made of GaAs/AlGaAs to be mechanically joined to long-wavelength alloys. An impractical method of producing devices in volume, it nevertheless allowed research into optically pumped long-wavelength VCSELs to progress. This past year saw several companies announce plans to release long-wavelength injection-pumped products in 2002 (see Fig. 1).Cielo Communications (Broomfield, CO), for example, has been sampling a 1310-nm VCSEL based on technology licensed from Sandia National Laboratories. It uses an active layer of InGaAsN, which can be lattice-matched to both a common GaAs substrate and to the GaAs-based Bragg reflectors. Cielo reports single-mode cw power above 1 mW, threshold currents below 3 mA, and operation at temperatures up to 125°C.

Spare change

Wavelength-division multiplexing relies on individual lasers at a fixed wavelength for each channel. A typical long-haul network might have 80 channels spanning the wavelength range of 1535 to 1565 nm (C-band) separated by 100-GHz intervals. A service provider must therefore have on hand spare lasers for each source that can be rapidly installed in case of failure. This inventory burden is expected to increase with the next-generation all-optical network, which will provide 160-channel capacity.

The need for maintaining a complex inventory of expensive spares would be alleviated by a tunable source. The "fiber-to-the-home" segment of the all-optical network will operate at the 1330-nm band, and tunable lasers in this range will also provide savings for a market in which deployment is already slowed by costs that exceed acceptable pricing. By some estimates, most cw laser sources will be tunable within the next few years, resulting in a multibillion-dollar opportunity for these devices.

The technical requirements for such a laser are complicated. It must remain stable at the selected wavelength, even when directly modulated in some applications, and have sufficiently narrow linewidth to preclude any output at wavelengths not selected for lasing. The tuning mechanism must be simple and span a sufficient range (substitute for enough individual-wavelength lasers) to make the added complexity worthwhile. The electronics, packaging, and beam must interface cleanly with the installation. In addition, the device must pass the same demanding Telcordia standards for reliability as the single-wavelength lasers.

Several different competing schemes have been used over the years to produce tunable lasers (see Laser Focus World, November 2000, p.109). Familiarity with Bragg grating technology, widely used in modern optical networks, has provided an advantage to the distributed Bragg reflector (DBR) approach. Bragg-reflector-based designs such as the grating-coupled sampled resonator (GCSR) can be tuned in situ.

The medium is the message

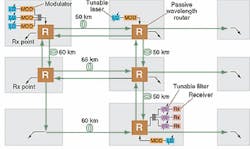

The ability to change wavelengths on the fly raises the other significant potential for tunable lasers—the dynamic reconfiguration of an installed network. In the so-called "metro" network, the high information-density terminations of long-haul systems, remote control of the laser sources would greatly simplify the complex task of routing signals and interfacing to the wide variety of local configurations demanded in this environment (see Fig. 2). For future WDM growth, additional channels could be added by switching to a new wavelength with an installed tunable laser.A proprietary design by Blue Sky Research (Milpitas, CA) for its “programmable laser” results in a device that can cover the entire C-band with switching speeds less than a millisecond. Blue Sky Research claims its product supplies at least 20 mW with a linewidth of less than 500 kHz and rejection of sideband wavelengths by 35 dB. Feedback from a miniature etalon is used to lock the output frequency. The company plans to offer the laser for sale in the first quarter of 2002.

When VCSEL technology is extended to WDM wavelengths, the same need will exist for tunable sources. The approach employed by Bandwidth9 (Fremont, CA) uses a microelectromechanical system to alter the resonant wavelength of an individual element in a VCSEL array. Last year, Bandwidth9 announced its MetroFlex tunable OC-48 transmitter for metro area networks at C-band or L-band with 100-GHz spacing.

The enthusiasm for the Internet resulted not just in an over-investment in the stock market, but also in the quantity of optical fiber buried in the ground. More fiber has been installed than is required by the present demand and than can be utilized by existing network technology. The availability of tunable sources will be a big step toward making full use of this buried resource in the future.

REFERENCE

1. Nagahama et al., Japanese J. Appl. Phys. (August 2001).

About the Author

Stephen J. Matthews

Contributing Editor

Stephen J. Matthews was a Contributing Editor for Laser Focus World.