Laser etching may help investigators ID bullets

Ultraviolet (UV) laser technology may someday enable law enforcement and forensics experts to irrefutably match a bullet to the gun that fired it. NanoVia, (Londonderry, NH) a company specializing in microvia technology (the drilling of connective electrical pathways between circuit-board layers), has developed a process for using micro-embossing mechanisms in rifles and handguns. Within a properly outfitted firearm, the embossing mechanism stamps shell casings as bullets are fired. The shell casings would then become invaluable forensic tools in an investigation.

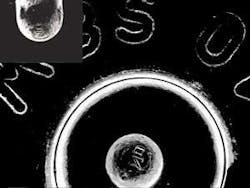

To test the technology, the NanoVia team replaced the firing pin of a SIG P229 0.40-caliber handgun with a SIG-certified pin laser-etched with raised characters (see figure). After firing the handgun 100 times, every 10th shell casing that was collected demonstrated consistent stamping and quality embossing. Further lifetime testing was performed via a test apparatus that stamped the pin into a block of steel for 30,000 cycles. The pin retained clear embossed marks that revealed minimal wear.

The etching process used a 1.5-W diode-pumped solid-state ultraviolet laser from Coherent (Santa Clara, CA) at 266 and 355 nm, coupled with a holographic-mask technology to rapidly produce two-dimensional bar codes or alphanumeric characters. The laser system etched the surface of the micro-stamp to create the raised characters.

null

A custom scanning optical system scanned the beam in multiple axes of motion, synchronized to the laser firing, to precisely etch the characters on the convex spherical tip of the test firing pin. The process is capable of producing character widths and lengths as small as 0.005 mm and raised heights from a few microns to 0.050 mm, with tolerances of ±0.0007 mm.

Because a firing pin is easily accessible, it was the most obvious vehicle to evaluate the technology's durability. "The ideal scheme, however, places the microstamp in the breach/chamber area of the gun, so that the identification cannot be altered or removed," says Todd Lizotte, NanoVia vice president of research and development .

In such a scheme, a metal rod is installed in the side of the chamber area against the brass cartridge casing of the bullet. When the firing pin hits the primer, within microseconds the pressure from the ignited charge inside the cartridge reaches greater than 30,000 psi. Heat presses the brass cartridge into the recessed microstamp, which embosses the casing with a depressed code, for example the serial number of the barrel.

Future-proofing

Is microstamping of a gun barrel practical? Bullets are already "fingerprinted" with score marks from the barrel as a gun is fired, a fact widely known since the Washington, DC, sniper shootings in October. Is it necessary to mark it in yet another way? John Keller, editor-in-chief of Military and Aerospace magazine, argues, "It's a technology searching for an application."

"True," says Lizotte. However, he says, out of 11 casings recovered in the DC sniper shootings, only 7 were conclusively linked to the shooter via barrel fingerprinting—a reliability of 63%. In the case of microstamping technology, the identification of casings would be conclusive and irrefutable. In addition, while a perpetrator can switch out a barrel for another one or scratch an existing one to alter its fingerprinting, microstamping of the breach/chamber area would be permanent and unalterable.

NanoVia says that the microstamping concept is not designed for retroactive implementation in existing guns. The technology is designed to "future-proof" future gun purchases with a built-in tracking capability through gun sales. "The longer we wait," says Lizotte, "the more weapons will be out there without ballistic tracking."