Solid-state illumination is on the horizon, but challenges remain

The output power of light-emitting diodes (LEDs) has risen steadily for decades, and at an accelerated pace in the past few years. With efficiencies that now far surpass that of incandescent lights, high-power LEDs are finding real-world application in automobiles and massive outdoor displays. Because LEDs can efficiently generate blue and green light as well as red, white-light and full-color devices are practical and have entered routine use.

At this rate of progress, area illumination with LEDs and direct competition with incandescent or even florescent lighting may seem at hand. But the challenges for white-light room illumination are formidable. Unlike lighting for displays, illumination requires very tight standards for the spectral quality and consistency of the light, standards that LEDs are, as yet, far from meeting. In addition, major cost reductions are required before LEDs can replace incandescent bulbs. Several companies are now in the race to develop the first practical illumination LEDs and the first new indoor light source since fluorescent lights.

Bigger and brighter

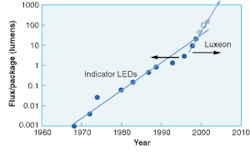

Since around 1968, LED luminous output (flux, which is measured in lumens) per "package" of LEDs has doubled every two years, following Haitz's law, just as the number of transistors on a chip has followed Moore's law at the same pace (see Fig. 1).1 In the past two years, growth of output has been even faster than this rate, so that the largest LED lights now produce 300 lumens, while in 1968 the largest output was a millilumen.

Efficiency of light output per unit of energy input has also steadily soared, so that today red-orange LEDs have reported efficiencies as high as 45% (more than 100 lumens/W) while short-wavelength LEDs have efficiencies of up to 25%. In contrast, incandescent lighting has an efficiency of only around 5% (7 to 10 lumens/watt) and fluorescent lighting 20% (35 to 40 lumens/W). The high efficiency and substantial brightness of LEDs have resulted in incandescent lights being replaced in such common applications as traffic lights and brake lights on cars.

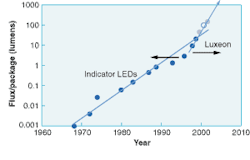

The development of short-wavelength LEDs using aluminum gallium indium nitride (AlGaInN) has made possible full-color or white-light high-power applications such as outdoor displays. While red-orange LEDs using aluminum gallium indium phosphide (AlGaInP) radiate at wavelengths from 590 to 650 nm, AlGaInN LEDs emit at 380 nm in the near-UV and 540 nm in the green. With phosphors to convert the UV light to blue visible emission, LEDs can be combined to produce a wide range of colors, as well as white light. Outdoor displays made from RGB diode units have been built as large as the sides of entire stores.

The existence of relatively powerful LEDs that can produce white light at high efficiency has raised hope for true solid-state illumination—that is using LEDs to light entire areas. The potential benefits are large. In the United States about 21% of all energy is consumed for lighting—8% for incandescent lighting and 13% for fluorescent lighting. Average efficiency of this lighting is only around 14%. If existing lighting could be replaced by LEDs functioning with around 30% efficiency, power consumption for lighting could be halved, a 10% drop in overall energy consumption. In addition, LEDs have lifetimes far longer than that of incandescent bulbs-50,000 hours or more, compared with 750 hours for bulbs.

However, solid-state illumination has not happened yet. Today's LEDs are still designed for displays that are intended to be looked at (see photo). In contrast, illumination light is powerful enough to work by reflecting off surfaces, and is not generally looked at. Indeed, several obstacles still lie in the path toward solid-state illumination.

Challenges for illumination

Currently, LEDs are beginning to achieve the output powers needed for illumination. At 5-W output, Luxeon LEDs (produced by Lumileds Lighting, a division of Agilent, San Jose, CA) produce 150 lumens, about the same as produced by a 20-W incandescent bulb, which occupies 100 times more physical volume. Since the LEDs are so small, packages of the devices can substitute in power for standard light sources—a dozen LEDs can replace an 1800-lumen automobile headlamp.

But area lighting, the basic illumination application, requires more than just light output. Human eyes evolved to see light from the Sun—a near-blackbody emitter—so are very sensitive to deviations of light source spectra away from that blackbody curve. The eye can accurately correct reflected colors that are illuminated by blackbody radiators at different temperatures, so colors look very similar when illuminated by a 3000 K incandescent bulb or by the 6500 K noonday sun. But deviations from blackbody spectra of as little as 2% are detected and make colors appear distorted. Color consistency from lamp to lamp and over time is particularly important, as variations in red and green flux of more than 3% and of blue flux of more than 10% are unacceptable. This consistency requirement is currently particularly difficult for LEDs to meet.

White-light LED radiation starts out very far from a blackbody, as a collection of narrow-line monochromatic emissions ranging from 650 to 380 nm. Three approaches can be used to convert that emission into something approximating a blackbody curve. The first and simplest is to just mix several monochromatic emissions in the right proportion to mimic the color response of a blackbody illuminator.2 By mixing three or more monchromatic sources a point in the color diagram can be reached that lies close to the coordinates of blackbody radiation (see Fig. 2). In this way a standard color-rendering index (Ra) of 80 can be achieved with three monchromators and of 90 with four monochromators. For comparison, a perfect blackbody has an Ra of 100, incandescent bulbs 90, and fluorescent lights 80.

A second technique uses a UV-emitting LED to pump three phosphors, emitting in the red, green, and blue parts of the spectrum. This has the advantage that a mix of phosphors can spread the light energy out into a good approximation of a blackbody spectrum, with excellent Ra. Nearly half the input energy is wasted, however, due to scattering and absorption, and the UV radiation rapidly deteriorates the LED package material.

A third approach, the most common, uses a blue LED to pump a complementary yellow-emitting phosphor. A portion of the blue light also escapes, combining with the yellow to produce white. Again, there are losses in efficiency as compared with the nonphosphor approach, although not as severe as in the all-phosphor method.

The main challenge to all these approaches is to reduce the variability of light output. Light-emitting diodes produced by the same process can vary in light output by a factor of two and may have different output wavelengths. Aging affects LED output as well as does temperature, with output decreasing about 10% for each 10% increase in temperature. Small variations in phosphor coating thickness can also affect light output.

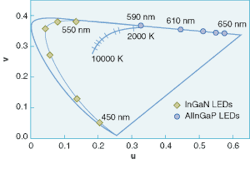

To compensate for these variations, manufacturers are implementing various types of feedback controls.3 One simple method is to use a set of three photodiodes to detect the flux from each LED in a package and correct the input to current to maintain a constant output. This technique can correct for LED flux variations with aging and temperature, but cannot correct for the shift in wavelength that also occurs with temperature.

An improvement is to also control the temperature itself (see Fig. 3). Another alternative is to use a feedback circuit that detects the actual point in the color diagram produced by the LED and corrects inputs to hold that point constant. This approach requires using color filters over each of three detectors to match the eye's sensitivities.

Experimental control systems developed at Phillips Research (Briarcliff, NY) have shown that it is possible to obtain adequate color consistency with the most advanced approaches in 98% of samples tested. As these feedback systems enter commercial products, the quality of LED lighting may soon approach that of fluorescent or even incandescent lights.

This still leaves one hurdle, however—the cost of the units themselves. Even without feedback circuits, high-power LEDs currently cost more than 100 times as much per lumen as light bulbs. Six $12 LEDs produce about as much light as a 50 cent 100-W light bulb. So costs will have to come down before LEDs can successfully compete with existing light sources (see "Solid-state lighting continues growth in down market," [below]). It should be noted though that since LEDs last 50 to 70 times as long as incandescent lights and consume only a quarter as much energy LEDs may already have lower life-cycles costs. Nonetheless, further drops in price would be needed to compete directly with fluorescent lights, which use less energy and are much longer-lived. Once feedback control issues are addressed, it may not be long before solid-state illumination becomes a reality.

REFERENCES

- D. A. Steigerwald et al, IEEE J. Sel. Topics in Quantum Elect.8, 310 (March/April 2002).

- C. H.Chen et al, IEEE Photonics Tech. Lett. 14, 908 (July 2002).

- S. Muthu, J. P. Schuurmans, and M. Pashley, IEEE J. Sel. Topics in Quant. Elect.8, 333 (March/April 2002).

Solid-state lighting continues growth in down market

Hassaun A. Jones-Bey

Senior Editor

Despite the weakened economy, solid-state lighting has managed to maintain a flat market performance. In 2001, the $1.2 billion high-brightness LED market stayed just about level with its performance during the previous year, according to Robert Steele, director of optoelectronics programs at Strategies Unlimited (Mountain View, CA), who was one of several presenters on the subject at this year's SPIE annual meeting (July 18–10; Seattle, WA).

"The high-brightness LED market held steady in a market where the rest of electronics and semiconductors were falling," Steele said. In fact, sales of high-brightness LED units actually increased in 2000, he said, but the overall market value remained constant because prices were down. Steele projected a return in 2003 to normal growth trends (not the greater than 50% rates of the telecom bubble, but possibly on the order of 20% to 30%).

Other speakers on solid-state lighting—including Shuji Nakamura (University of California, Santa Barbara), Lumileds (San Jose, CA) CEO George Craford, and James Brodrick from the U.S. Department of Energy—all indicated that increasing academic, industry, and government resources are focusing on continuing the growth of LED illumination technology from its current inroads into specialty lighting applications, and toward the very attractive horizon of general illumination.

More 'R' than 'D'

In discussing technological avenues that are being explored to improve LED brightness and efficiency, as well as research into short-cavity VCSELs as light sources, Nakamura mentioned the increased brightness to be obtained from LEDs cut into beveled rather than square shapes. He said that among commercially available chips, those produced by Cree (Durham, NC) are the brightest because of "chip-shaping technology," which substantially improves light extraction.

Conference co-chair Ian Ferguson (Georgia Institute of Technology; Atlanta) characterized Nakamura's comment about chip shaping as an example of the transition of solid-state lighting efforts from the strictly research side of the R&D equation to the development side. The decision to move the conference program several years ago out of its traditional home as an LED conference in the Photonics West program and into the SPIE annual meeting with a focus on illumination was made with these types of concerns in mind, according to Ferguson. Ferguson directs a Focus Research Program on energy-efficient next-generation lighting at Georgia Institute of Technology.

"Rather than worry about bringing together semiconductor physicists to talk about the devices, I was more interested in a meeting with people who knew and understood general illumination as well as semiconductor physicists and device engineers," Ferguson said. "So we moved it to this summer meeting (alongside existing illumination conferences) just to make that break. We're not only looking at this from the device aspect, but we're looking all the way through to the applications and how these new devices can be used."

The primary obstacles to solid-state lighting for general illumination involve getting enough photons out of solid-state devices to replace the brightness of existing sources, and also with getting those photons out efficiently enough to compete with the cost of existing sources, Ferguson said. Nakamura agreed, noting that the solid-state target for general illumination is about 200 W/lumen, while existing sources are in the low 10s.

Yet the increasingly competitive performance of solid-state LEDs in specialty lighting applications was also made clear by numerous observations, such as the fact the Lumileds solid-state white LED at about 30 lumens is very close to replacing the automotive headlamp. Nakamura also mentioned two new phosphors developed at Sarnoff Labs that were evaluated for solid-state lighting at University of California, Santa Barbara. While the red yielded a relatively low quantum efficiency of 25%, green quantum efficiency was a very high at 74%.

Development of phosphors specifically for generating solid-state white light was a major focus of Craford's presentation. He also spoke of an "LED performance revolution" with examples such as the fact that a traffic light used to require 700 5-nm LEDs, but can now be replaced with about 10 high-brightness LEDs. Nonetheless a 100-fold cost reduction will have to take place before LED illumination can become fully competitive with existing devices, he said.

While mentions of chip-shaping technology and advances of LEDs in specialty lighting applications indicate the growth on the development side of the R&D equation, numerous points by Nakamura and Craford, such as the need to increase efficiency without sacrificing color rendering or input power (in the case of the nitrides), indicate that plenty of research is still needed.

"We are still in a technical transition where the focus is more on the 'R' for research rather than the 'D' for development," Ferguson said. "Researchers are still addressing the core research issues in solid-state lighting at this time rather than focusing on how to make it more cost-competitive general illumination."

Brodrick sounded a hopeful note for research funding on behalf of the DOE Office of Energy Efficiency and Renewable Energy, Buildings Technologies Program, which focuses on lighting technology research "to increase end-use efficiency in buildings." Efforts in fiscal year 2002 include a project with Cree to develop white LEDs for general illumination; with General Electric (Fairfield, CT) to develop organic LEDs for general lighting; with Lumileds concerning development of key technologies for LED based white lighting; with UC-Santa Barbara for high-efficiency, nitride-based solid-state lighting; and with UC-San Diego to improve the efficiency of solid-state light sources.

While DOE funding for solid-state lighting research is currently on the order of $6 million per year, Brodrick said that federal legislation for the Next Generation Llghting Initiative would provide funding on the order of $50 million for the next 10 years.