Fiber lasers rapidly gained traction in the market after their introduction as an industrial tool. High-efficiency turnkey systems that were compact, cost-effective, and robot-friendly delivered output with beam properties suitable for remote cutting and welding—attributes that made these lasers practically irresistible in many industrial settings. More recently, the advent of fiber-based femtosecond systems has served to further drive fiber laser growth by making ultrafast laser technology much more accessible. "Fiber lasers are bringing femtoseconds to the masses," says contributing editor Jeff Hecht in his Photonic Frontiers feature this month, which examines the state of current femtosecond fiber laser technology (see http://bit.ly/8yVBQk). Meanwhile, researchers continue driving development of these lasers for a variety of applications as well as furthering fundamental research—the application of chirped-pulse amplification to a femtosecond-fiber system in Germany has produced some impressive results (see page 25 and cover).

There have also been some interesting recent developments at the leading edge of semiconductor laser technology. In the visible spectrum, the commercialization of green-output diode lasers (as opposed to green frequency-doubled solid-state lasers) took another step forward in January when Shuji Nakamura's startup company Kaai (Goleta, CA) demonstrated green- and blue-emitting diode devices at the 2010 Consumer Electronics Show in Las Vegas (see http://bit.ly/6zQDM5). There are some potentially huge markets for these devices including tiny projectors and television. And in the mid-infrared, quantum cascade lasers have also been advancing—performance breakthroughs have led to commercially available multiwatt devices. Applications of these lasers include gas sensing, explosive detection, and medicine. Some of the latest results include a record-high continuous wave, room temperature output of power from a single facet (see page 30).

Even leading-edge lasers need their output beams profiled and today's state-of-the-art characterization systems have evolved to use the latest in megapixel CCD and CMOS digital cameras, infrared-detector-array cameras, and a large variety of optical beam accessories, according to industry consultant Roger Rypma, who details the basics of beam characterization starting on page 50.

About the Author

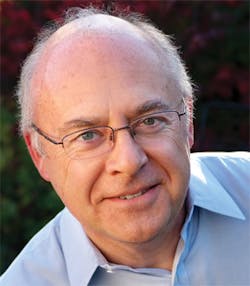

Stephen G. Anderson

Director, Industry Development - SPIE

Stephen Anderson is a photonics industry expert with an international background and has been actively involved with lasers and photonics for more than 30 years. As Director, Industry Development at SPIE – The international society for optics and photonics – he is responsible for tracking the photonics industry markets and technology to help define long-term strategy, while also facilitating development of SPIE’s industry activities. Before joining SPIE, Anderson was Associate Publisher and Editor in Chief of Laser Focus World and chaired the Lasers & Photonics Marketplace Seminar. Anderson also co-founded the BioOptics World brand. Anderson holds a chemistry degree from the University of York and an Executive MBA from Golden Gate University.