Nitride LEDs: Multicolor InGaN nanowire LED arrays span the visible spectrum

Indium gallium nitride (InGaN)-based LEDs have revolutionized the lighting and other industries, leading to high-power white-light LEDs, among other achievements. However, due to properties of bulk InGaN, conventional InGaN LEDs can only be made to emit light at wavelengths between the UV and the green spectral regions; other LED colors are achieved either by the use of phosphor or by the addition of other LEDs of different composition (for example, indium gallium aluminum phosphide red-emitting LEDs).

Now, researchers at McGill University (Montreal, QC, Canada), New Jersey Institute of Technology (Newark), and Samsung Advanced Institute of Technology (Suwon-si, South Korea) have fabricated phosphor-free red, orange, yellow, green, and blue InGaN nanowire LED arrays monolithically integrated on silicon (Si). To create different colors, only the nanowire properties need be changed.

Dot-in-a-wire structure

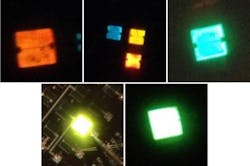

The InGaN/GaN quantum-dot-in-a-wire heterostructures are created via a three-step growth process using radio-frequency plasma-assisted molecular beam epitaxy (MBE) on a large-area patterned Si substrate. The emission wavelengths depend on the sizes and compositions of the dots. The researchers grew different types of multicolor arrays that included emission wavelengths ranging from about 450 to 700 nm (see figure). Nanowire LED array elements with sizes of 300 × 300 μm, 100 × 100 μm, and 50 × 50 μm were fabricated.

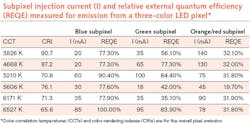

In a result that has potential for lighting LEDs, three-color LED pixels were created, consisting of a blue, a green, and an orange/red subpixel, all of which could be separately biased and thus changed in intensity. In one example, color-correlation temperatures (CCTs) between 3826 K (warm white) and 6527 K (a very cool, bluish white) are created by the pixels (see table). Other LED combinations produced CCTs between 1900 K and 6800 K.

The researchers plan to boost the carrier-injection efficiency in future devices, as well as fabricate these LED arrays on transparent substrates (via transferral from Si) to enhance the light-extraction efficiency, as well as on copper substrates for more effective thermal management.

“Using high-resolution lithography techniques, the pixel size of this RGB InGaN/GaN dot-in-a-wire LED can be further reduced to submicron scale,” says Zetian Mi, an associate professor at McGill University and one of the researchers. “These nanoscale LEDs will be well suited for high-resolution display and imaging applications. It would also be of interest to develop monolithically integrated color-tunable nanowire surface-emitting lasers to achieve controlled directionality and high output power, enabling the development of compact and miniaturized high-performance RGB laser light sources for high-resolution displays.”

REFERENCE

1. R. Wang et al., Opt. Express 22 (2014); doi:10.1364/OE.22.0A1768.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.