Two years of development have resulted in a commercial blue-emitting microchip laser from New Lambda of Clearwater, FL. The device emits 50 mW at 473 nm.

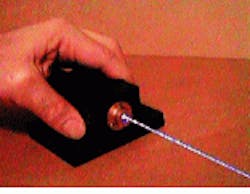

Company founder, Yutaka Shimoji, started New Lambda intending to mass-produce lasers. "It has always been in my heart," Shimoji says, "to produce a low-cost, good-quality, mass-market laser." The bridge to mass production is the microchip. The company has developed three diode-pumped solid-state blue-emitting lasers using microchip technology (see Fig. 1 on p. 36).

The laser cavity is produced by adhering two different crystals to each other to create a wafer. Thus, Nd:YAG and potassium niobate (KNbO3), for example, produce the 473-nm laser. Alternatively, for emission at 457 nm, Nd:YVO4 and KNbO3 are used, or—for 430 nm—chromium-doped LiSAF and KNbO3. The wafers are then cleaved into microchip lasers. Each chip is an individual monolithic laser cavity and is pumped directly by a diode laser.

Quiet cavity design

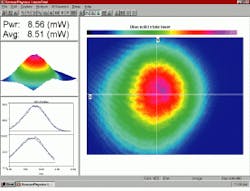

Although other companies are doing something similar, their lasers exhibit 5% to 10% noise, says Shimoji. He claims that the cavity design of the New Lambda devices produces a lower noise output. The New Lambda laser does not directly double the diode output; instead it uses intracavity frequency doubling of the solid-state device. The laser can be operated in single longitudinal mode, which means better long-term stability, lower noise, and excellent beam quality (see Fig. 2)."This can compete with gas lasers," says Shimoji, "and potentially can be manufactured at a low price." If microchips are purchased in bulk, Shimoji predicts that he will eventually be able to sell a laser for between $400 and $600, although the introductory price of the 473-nm device will be between $2000 and $3000. "We are talking about high-volume production," Shimoji says. "The lasers must sell at a low price to open up the market."

The 457-nm and 430-nm lasers will be launched in the near future. Potential applications include biomedicine—such as diabetes monitoring—and specialized erasable optical disks. "One can only imagine what we can do with a small, low-cost, diode [type] laser," says Shimoji.

The company recently applied for a patent regarding use of the microchip lasers for curing certain polymers. New Lambda is currently a four-person company with numerous investors. Shimoji hopes to take the company public within the next six months.

About the Author

Laurie Ann Peach

Assistant Editor, Technology

Laurie Ann Peach was Assistant Editor, Technology at Laser Focus World.