Femtosecond laser carves refractive-index-sensing F-P cavity in optical fiber

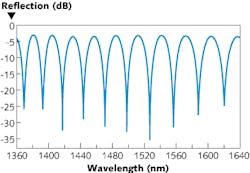

Yi Liu and Shiliang Qu of the Harbin Institute of Technology (Weihai, China) have used femtosecond-laser-induced water-breakdown machining inside a silica optical fiber to carve out a walled, partially enclosed cavity, then using an arc discharge to anneal the configuration, creating a high-quality Fabry-Perot interferometer (FPI) cavity with flat axial surfaces suitable for sensing the refractive index of liquids. The FPI cavity has a fringe visibility of almost 30 dB and a reflection loss of only -3 dB. The resulting sensor has a sensitivity of 1147. 48 nm/RIU (refractive-index units), a measurement accuracy of 1.29 × 10-4 RIU, and very little temperature sensitivity.

The initial cavity was hollowed out using a Ti:sapphire regenerative amplified laser by Coherent (Santa Clara, CA) that had a 1000 Hz repetition rate, an 800 nm central wavelength, and a 120 fs pulse duration; an aperture, optical attenuator, and mechanical shutter provided additional control of the beam, which was focused with a microscope objective. The single-mode fiber being machined was immersed in water to cause a bubble-, shock-wave-, and high-speed-jet-induced breakdown effect. The FPI cavity was then annealed with an electric arc for 0.2 s. The final cavity had an interference length of about 40 μm; its index-sensing ability was tested using solutions of glycerol and water in differing proportions. Contact Shiliang Qu at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.