Flowing neodymium offers improved heat management

Scientists at Lawrence Livermore National Laboratory (LLNL; Livermore, CA) believe that they may be able to significantly reduce the weight, volume, cost, and technical complications of a so-called solid-state heat-capacity laser (SSHCL) currently under development by replacing the solid gain medium with an inexpensive liquid (a heat-capacity laser has a cooling system that is deliberately undersized for weight savings, at the cost of allowing the laser medium to heat significantly). So far they have demonstrated diode-pumped continuous-wave (CW) laser operation in an inorganic flowing liquid host containing neodymium (Nd3+) ions, transversely pumped by 802-nm laser diodes.

The laser was operated in heat-capacity mode, and an output power of 1.2 W at 1053 nm was obtained from a flow cell with an excited volume of 0.4 mm square by 10 mm long, similar in operation to that of a similarly sized glass laser. In addition, significantly improved heat management over the SSHCL design was achieved because the circulating laser fluid gradually increased in temperature with no effect on the performance.

The advantage of this arrangement is that the design of the laser can now be decoupled from the demands of the thermal reservoir, allowing each component to be separately optimized, explained Karl Scheibner, a codeveloper of the system along with Brian Comaskey and Earl Ault. The initial demonstration was an outgrowth of an internally funded R&D effort, Scheibner added.

"We had minimal funding, but we were pleased with the results and are confident that, with additional funding, this new technical approach to high-power lasers with essentially no optical distortions could be reduced to practice," he said. "If so, a number of new applications such as materials processing, weapons, and power beaming to remote platforms for electricity or heat would become accessible."

CW-diode source eliminates distortions

The idea of dissolving Nd3+ in a liquid host actually dates back to the 1960s, Scheibner said. It was abandoned at that time, because the only excitation sources were flash lamps. Therefore optical distortions were large and varied from pulse to pulse with complex temporal and spatial dependencies. The Livermore design overcomes these problems, however, by using CW diodes for the excitation source and borrowing proven flow technology from their Atomic Vapor Laser Isotope Separation (AVLIS) program, in which the flowing dye-containing solvent passes through the flow channel. Flow conditioning and specific cell geometry leads to laminar flow—a diffraction-limited dye laser output of approximately 5 kW for hundreds of hours was demonstrated.

In the LLNL SSHCL testbed laser, the Nd-doped slabs heat up to about 100°C over the course of several seconds and then require time to cool down again. For military applications (100 kW is the current target average power), the laser can only be on for perhaps 10 seconds before the lasing medium must be allowed to cool. The most recent SSHCL designs increase the "on" time by moving new slabs into the lasing channel while the heated slabs are cooled offline (see Laser Focus World, December 2003, p. 42).

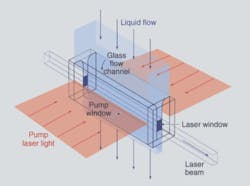

The liquid lasing medium, however, continuously circulates through the lasing zone and back through an offline reservoir (see figure). Pump light is injected perpendicular to the flow, and lasing takes place in the third dimension. Typical residence time for the fluid medium within the lasing zone is a fluorescent lifetime (approximately 350 µs), and the typical temperature rise is on the order of 0.2°C.

As the liquid passes through the lasing channel, it absorbs the diode pump energy and heats up. The liquid is continuously heated as it flows through the channel, causing refractive-index changes and distortions in the optical beam. But rapid circulation of the liquid drastically reduces temperature excursions across the lasing channel, and with suitably uniform diode pumping, careful Nd concentration selection, and flow conditioning, the researchers were able to confine the bulk of the thermal optical distortion to an optically benign tilt that was subsequently nulled by setting up two cells under equal pump loads but with opposite flow directions.

"The advantages with the liquid approach are numerous," Scheibner said. "In heat-capacity mode, the increase in laser run time requires no change in the lasing flow channel, just increases in the reservoir volume. There is also no thermally induced birefringence, as is seen in solid-state lasers, and there are no thermally induced fracture limits to worry about. In addition, the gain media is much less expensive than the highly polished defect-free crystal or glass hosts of solid-state lasers, the liquid does not optically damage, and the replacement of the media is trivial."