QCL modules are ready for industrial applications

Putting QCLs in standard packages and developing a driver module and control unit allows them to be used for industrial spectroscopic identification of molecules.

With the development of industrial-quality quantum-cascade lasers (QCLs), stable radiant sources that emit in the mid-IR at ambient temperatures will become available. This opens a spectral range for industrial-sensor applications in which the fundamental bands of many molecules permit highly sensitive, selective, and quick spectroscopic measurements in much less than a second.

When bringing such a diagnostic method from the laboratory to practical application, industrial requirements such as easy handling, fast laser replacement, and availability must not be disregarded. For laser diodes, this especially applies to their easy adjustability. In the past year, many basic devices for use with spectroscopic laser diodes have been developed, moving commercial uses for such laser diodes closer to reality.

Technical background

Optical-absorption spectroscopy has been increasingly recognized as a diagnostic method that solves many sensor-technology problems. Whether at low or normal pressure, in the reactive environment of plasma-based coating processes or in environment analysis, the Lambert-Beer law of absorption is applicable to identifying, monitoring, and measuring the concentration of molecules.

Various groups have reported on the measurement of, for example, hydrocarbon concentrations in plasma coating equipment.1 These hydrocarbons not only include the stable molecules methane, ethane, ethene, and ethyne, but also the more-reactive radical components such as the methyl radical CH3. Examples such as the practical sensing of oxygen show that an industrial realization of the method is possible.

Since the invention of the QCL in the mid-1990s at Lucent Technologies Bell Laboratories (Murray Hill, NJ), research on such laser structures has been ongoing at many locations, especially in Europe. With research activities concentrating mainly on the actual semiconductor structures and their radiation properties, applications such as the processing of laser chips in standard packages were initially given a back seat. We believe that exactly this adaptation needs to be accomplished and, additionally, that a laser controller should be made available so that those interested in this technology can fully concentrate upon its application.

QCL in a standard package

The development of QCLs in standard TO-8 packages is an important step toward industrial applications. The delicate chip is temperature-controlled with a Peltier element, supplied with current, and simultaneously protected both mechanically and chemically. A tight-fitting cap allows the device to be filled with an inert gas, excluding oxygen and humidity. This makes the processing of sensitive raw materials in the chip possible and simultaneously increases the lifetime of additional components such as heat sink and temperature sensor.

The material for the cap's wedged window is selected based on the emission wavelength (a wedge reduces feedback into the laser cavity). An optimum between transmission and manageability is of central importance. Especially in the mid-IR range, the transmission of the window is generally only guaranteed through the use of very specific crystals such as zinc selenide or barium fluoride. These crystals are often difficult to clean if they are soluble in, for example, alcohol or acetone, or if they are hygroscopic.

The internal construction of pulsed QCLs can be optimized for use in ambient environments. A Peltier element incorporated to stabilize the temperature produces a temperature deviation of 66 K with a maximum current of 1.8 A. Heat dissipation from the chip to the Peltier element is established via a heat sink. The use of standard packages also permits the use of Peltier elements that differ in power and dimension, making it possible to tailor the design to special requirements. Larger TO-style packages, as well as multilevel Peltier elements, are conceivable. For the current design, a single-level Peltier element in a TO-8 has proven ideal.

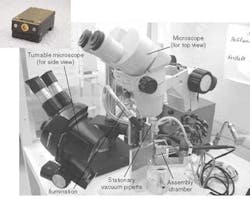

For manufacturing, a QCL workstation was developed in which various edge-emitting lasers as well as QCLs from various manufacturers can be placed in standard packages (see Fig. 1). An assembly chamber can be equipped with various assembly tools as well as two microscopes that allow the viewer to monitor the process from two different directions for precise positioning. A vacuum pipette permits careful handling of the semiconductor components.

Compact controller unit

The operation of QCLs places high demands on the electronics. For this purpose a driver module and controller unit was produced that was adapted for pulsed QCL operation at ambient temperature. The modular driver module can be integrated into most process controllers and is used for activating and monitoring the laser diode. Pulse widths of 22 to 300 ns can be generated at frequencies of 1 Hz to 200 kHz. Current and voltage drop at the laser diodes can be observed in real time. The laser-diode pulse regime—amplitude, repetition rate, and pulse-duty ratio— can be controlled externally.

The controller unit is used to control current and temperature. It sets the driver module and permits observation of the operating status and temperature on the Peltier element. Together with the integration of QCL chips into standard packages, these two modules make up an industrially suited QCL source. This can be seen in the fact that a laser exchange, including resetting, can be achieved within 15 minutes.

Results

Properties of the radiation modules, consisting of single- and multiple-mode QCLs with current and temperature controllers, were measured using reference measurements on various laser structures.

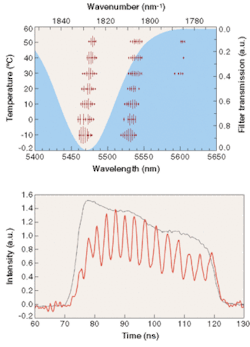

FIGURE 2. A Fabry-Perot QCL in a TO-8 can has a multiple mode structure that varies with temperature (top; I amp = 4 A; f = 2.5 kHz; tpulse = 50 ns). A narrowband optical filter can select certain modes (the area not hatched shows the filter transmission range). This filter signal is normalized and actually has a maximum transmission of 60%. A monochromator can be used instead for mode filtering of a multiple-mode QCL (bottom). The black curve is the laser signal, while the red is the laser signal filtered by a germanium etalon. The expected interference structure of the etalon is clearly seen.

For multiple-mode measurements, the Walter Schottky Institute (Garching, Germany) supplied laser structures (QCL chips) for multiple-mode lasers as part of a joint research project supported by the Bavarian state government.2 In a multiple-mode indium phosphide QCL, the temperature on the Peltier element is varied for constant-pulse conditions—constant amplitude, pulse length, and pulse-repetition frequency (see Fig. 2). Aside from the main mode at 1827 cm–1, two auxiliary modes at 1807 cm–1 and 1787 cm–1 are found. The mode has a typical width of 3 to 5 cm–1 and its length is a continuous function across several temperatures. Substructuring represented by vertical lines illustrates the additional local maxima found in the main mode using the monochromator. Each vertical line represents a local intensity maximum; the longer the line is, the greater the radiation intensity. The integral radiant power in the pulse is greater than 500 mW.

Given an appropriate choice of operating conditions and mode selection, multiple-mode lasers can be used for spectroscopic applications. According to information received from chip manufacturers, much lower prices for multiple-mode laser structures can be expected for future production QCLs.

Not only are monochromators suitable for mode filtering, but very narrowband interference filters in the mid-IR are also suitable for filtering a special mode. In the range of 1 to 20 µm, the central filter curve positions can be adjusted to the desired mode. The bandwidth can be 0.9% to 6%. In our example, the distance between the laser's main modes amounts to about 20 cm–1, the maximum filter transmission is 60%, and the full width at half maximum is 2%. The anomaly in using a filter is that its transmission wavelength is not variable. On the other hand, the costs are only a few percent of the cost for a monochromator.

Single-mode QCLs

Single-mode QCL chips generally contain a distributed-feedback (DFB) grid. The DFB laser structures used were developed by Professor Strasser's work group at the Technical University in Vienna.3 In preliminary investigations, the single mode was verified using a monochromator, and a pulse power of approximately 100 mW was measured, confirming that single-mode DFB laser diodes have a lower pulse power than multiple laser diodes.

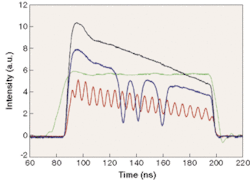

Due to the single-mode character of the IR radiation, it was possible to forgo using a monochromator to measure signals from a single-mode laser diode at 883 cm–1 (see Fig. 3). The 883 cm–1 line is suitable for measuring ammonia that contains isotopic nitrogen (15NH3). On the basis of the etalon fringes, which have a pitch of 0.05 cm–1, the spectral position could be clearly identified. Across the entire temperature range of –10°C to 50°C, a tuning of 0.05 cm–1/K was found. The resulting total tuning range of 3 cm–1 allows great control of the emission wavelength of production QCLs. A somewhat higher spectral tuning of 0.07 cm–1/K was found for other DFB laser structures at 1054 cm–1, a line identified using 14NH3, the main form of ammonia.

REFERENCES

- L. Mechold et al., Plasma Sources Sci. Technol. 10, 52 (2001).

- N. Ulbrich et al., IEEE Electron. Lett. 37, 1341 (2001).

- W. Schrenk et al., Physica E 13, 840 (2002).