Microsphere-doped acrylic rods mix colors

Researchers at the University of Technology Sydney Department of Applied Physics (Sydney, Australia) have used doped acrylic rods to color-mix LEDs, producing superior white light when compared with mixing using plain acrylic rods.1

Two common methods are used to produce white light for illumination from LEDs: mixing red, green, and blue LED chips in a discrete or clustered package (RGB LEDs); and coating blue- or ultraviolet-emitting LED chips with phosphors. The RGB LEDs produced by the first method can be used to provide a full spectrum of 256 colors, as well as uniform white-light illumination, through current and voltage control of the individual LEDs.

Using light guides for LED mixing is a common technique used in illumination displays and projectors. Unfortunately, undoped light guides (in this case acrylic rods) produce unwanted patterns with obvious color separation. The researchers eliminated these color patterns by incorporating transparent refractive-index-matched microparticles (TRIMMs) into short acrylic rods, producing a homogenized white-light source with a diffuse output while reducing source glare and improving illumination uniformity.

The process of using TRIMM particles resulted from a collaborative effort between the university researchers and Poly Optics (Burleigh, Australia). The researchers had initially developed a product called “super side light,” which is a solid-core optical fiber in flexible polymer that incorporates TRIMM particles to produce uniform illumination along the length of the fiber. Unlike other illumination products that use lines of LEDs and arrays that are either nonuniform or involve relatively expensive optics, the researchers say the TRIMM particle-doped flexible fiber they developed is relatively low in cost. This polymer product is currently available for a variety of illumination uses in diameters from 5 to 20 mm and can produce significant “neon” quality lighting using even 20-mA LEDs at one or both ends.

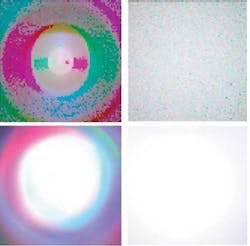

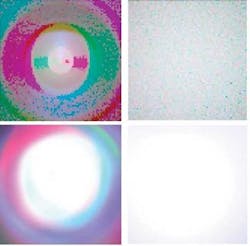

In the experimental setup, an array of 3-mm red, green, and blue LEDs was mounted in close proximity to both doped and undoped acrylic rods 12.7 mm in diameter and between 8.84 and 10 cm in length. The doped rods contained TRIMM particles with an average diameter of 35 µm and were of two concentration levels, 0.45% and 3.0%. Modeled, photographed, and measured color distributions were taken 10 cm from the exit end of the acrylic rods, revealing that only the doped mixing rods produced uniform illumination over a large area (see figure).

Modeled and photographed results from an array of red, green, and blue LEDs as input to both undoped and TRIMM-doped acrylic rods are viewed as images 10 cm from the exit of the acrylic rods (images are 80 mm across). The color separation is evident in both the modeled (upper left) and photographed (lower left) image when using an undoped rod for mixing, while the modeled (upper right) and photographed (lower right) result from the TRIMM-doped rod produces a more desirable white-light result.

Commercial RGB LEDs are packaged in housings much smaller than the large footprint of the discrete LEDs and acrylic rods used in the experimental setup. In these small commercial packages, manufacturers typically use bare LED chips and micro-optics for beam concentration. While the research related to TRIMM particle-doped mixing rods is currently applicable to large-scale fiberoptic illumination projects such as those being undertaken by Poly Optics, the researchers are continuing to focus on key application issues and on optimizing the size and configuration of the mixing rods to remove remaining losses due to Fresnel reflections that occur at both ends of the rods. Despite these Fresnel losses, the rods are efficient mixers with very little light loss when compared to phosphor white LEDs that lose energy in converting some of their photons to other wavelengths. In addition, the TRIMM-particle concentration, source LED-array configuration, and screen distance from the output of the rods can be altered to suit different applications.

The researchers have filed patents internationally on the TRIMM-particle mixing process and are currently seeking partners or licensees interested in obtaining the mixing rods as the key optical component.

REFERENCE

1. Chris Deller et al., OSA Optics Express12, 15, (July 26, 2004).