Laser coding turns food packages into miniature billboards

Barcodes were just the beginning. The bottles, boxes, bags, cans, cartons, and containers that keep our food and beverages fresh can now be imprinted with all kinds of tracking and marketing data.

They may seem harmless to the consumer: those tiny adhesive labels affixed to each piece of fruit in the produce section of your local supermarket. But for years they have been the bane of produce packagers. Required by law, those innocuous little labels are actually quite costly, requiring specialized equipment and huge label inventories specific to each product, type, size, quality, and producer. Furthermore, they are limited in how much information they can carry and the food items to which they will adhere.

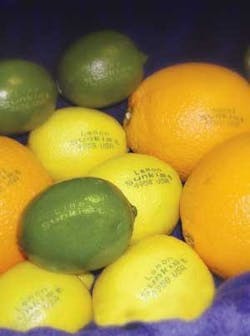

Now a laser-based method for gently marking directly onto the skin of any fruit or vegetable has the food industry thinking it may be able to eliminate those pesky labels and the associated overhead. The Produce Laser System from Durand-Wayland (LaGrange, GA) uses a CO2 laser to produce a permanent, legible identifying mark on the skin of fruits and vegetables without degrading product quality or flavor. The scanned beam laser (from Linx Printing Technologies; St. Ives, England) uses 10 to 50 W of output power to produce a dot-matrix code directly on the surface of the produce, removing some of the skin pigment and leaving a contrasting mark (see Fig. 1). Advantages include instant product look-up (PLU) changeover, elimination of the adhesive labels, environmental and health compatibility, traceability, information storage, no consumables, and the ability to do country-of-origin labeling when necessary.

The system identifies and makes an appropriate mark as the fruit moves along the production line. “One piece of fruit gets a certain PLU number, while the second piece is a different size that gets a different label,” says Greg Drouillard, the engineer who developed and patented the PLS process and sold the rights to Durand-Wayland in 2002. “This is conventionally done with a bank of label machines, so the more variety you have, the bigger the inventory of labels needed, which also raises the maintenance cost. But the PLS requires just one laser and one head per line. You have instantaneous messaging of different types that you can use without raising the cost or increasing the consumables.”

Durand-Wayland has licensed the system to Sunkist and is working to do the same with other produce companies worldwide. In addition, Drouillard expects to have a second laser-based system, for coding nonperishable items, on the market this year.

Beyond barcodes

Laser marking and coding is certainly not new to the food industry. Marking and coding of products first began with expiration dates in the food and pharmaceutical arenas.1 Today food and beverage products are routinely coded with lot codes, real-time dates, barcodes, and a myriad of other types of information. The most common technologies for marking and coding are thermal transfer coders, inkjet printing systems, mechanical embossing systems, and print-and-apply label systems. While all of these have their place, the advent of compact, robust, lower-cost lasers and more-sophisticated software is making laser coding a preferred method for marking all types of food and food products.

The use of lasers for marking and printing applications is relatively new. “Laser-imaging development is in its infancy, whereas other approaches, such as inkjet, are at the end of their development,” said Steve Kelly, managing director of Sherwood Technology (Widnes, England), a company focused on the development of color-change compounds and processes for high-speed printing of images. “But the industry is ready for the next thing, and now we have this new technology that is more cost-effective, plus there are some legislative drivers for tracking and tracing, and emerging trading standards. So the prices are coming down to be able to compete with inkjet systems, and volumes are going up.”

With the issue of traceability becoming increasingly important in recent years (particularly for product recalls and for verifying a food item’s country of origin) food and beverage manufacturers worldwide have turned to laser-based coding/marking to improve code quality and reliability, reduce downtime, and eliminate consumables. Using a scribing or dot-matrix laser system from Domino (Cambridge, England), for example, these companies are able to create more-defined, clearer, and precise alphanumerics compared to conventional methods, on materials that vary widely in size, thickness, texture, and shape. Domino’s DSL1 scribing laser uses a sealed CO2 laser (10 to 50 W) galvanometer combination to code and mark text, data, and graphics up to 180‑mm high at production-line speeds up to 1300 ft/min.

Another Domino system (DDC3) also uses a sealed CO2 laser with seven separate laser heads to mark a variety of substrates, from ceramics to thermoplastics. A curved-surface system, designed specifically for the beverage industry, enables a legible code to be placed directly on the neck of a bottle, avoiding the bow-tie effect often seen with other marking methods.

The Durand-Wayland PLS can also handle a variety of surfaces and sizes, and a proprietary feedback mechanism allows the system to determine and adjust for the depth of each produce item it encounters. Drouillard declines to discuss the feedback system in detail but says the PLS functions as a “slave” to a sizer, which uses size and grading to determine what each item is. The system can mark PLUs, trace codes, and date and time stamps in 14 different languages; it can also convert any kind of image into a matrix that can be printed. It works on just about any fruit or vegetable-even onions (whose epidermis is only 18 µm deep)-at processing speeds of up to 17 items per second. For fruits such as lemons that do not have good contrast, a small amount (10 picoliters) of natural, FDA-approved food coloring is used for contrast enhancement.

“This process has to be done in one-quarter second of the laser ablation, and it doesn’t rub off or sweat off, which is one reason you don’t see inkjets doing this,” Drouillard said. “The biggest thing to overcome is to keep the mark on the surface without penetrating it.”

Changing colors

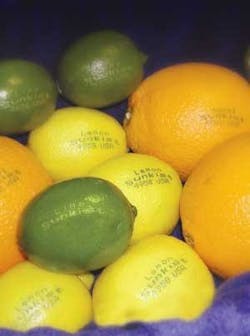

Other developers of coding technology are blending photodynamics with laser printing to improve laser-based date coding and traceability marking. The DataLase color-change process from Sherwood Technology is a chemical approach that allows a laser to print images with very low power at high speed. The process uses only a fraction of the normal output of a CO2 laser (less than 10 W), enabling high-speed marking of difficult substrates such as metals, glass, and non-laser-sensitive coatings and materials (see Fig. 2). The compound is applied to the surface of a product or package in a patch; when exposed to the laser beam, the patch changes from neutral to black to produce a permanent mark. There are no solvents, inks, or consumables at the point of coding so this approach offers several speed, handling, and environmental benefits.

“With DataLase we have patented a chemical compound that absorbs very strongly in the 10.6-µm range,” Kelly said. “The pigment absorbs the laser wavelength, causing a change in the pigment. The result is the ability to write like a pen on a surface.”

According to Kelly, one of the biggest issues that has held back laser coding in packaging is that lasers are not physically suited to marking (burning) all materials. But he maintains that combining the DataLase process with low-power CO2 lasers makes it possible to mark all kinds of materials, including plastic, glass, metal, and fabric.

“If you look at primary packaging, such as Frito Lay chips or Budweiser labels, it is generally printed and decorated by the supplier, who puts fluid coating on the labels and packaging. We make carefully formulated inks that can be applied at the same time during the printing process,” Kelly said.

In addition, because the laser beam can pass through polypropylene films, DataLase can be used to embed an image between two films, making it completely tamper-resistant. Sherwood is able to manipulate the wavelength of the laser to pass through the outer film with enough energy to create the image in the DataLase film. The company is now working to develop other compounds that will be compatible with semiconductor lasers and ultraviolet lasers for printing and marking. An “edible” version of DataLase based on food additives can be applied to drug tablets, eggs, and other foods.

“We don’t want to be a laser manufacturer; we want to create a laser/chemistry package for a variety of applications,” Kelly said. “But our development activity as we go into the next generations (of DataLase) involves us in the development of the laser systems as well. We want to create laser specs that are fine-tuned to the chemistry, and we want to find the most cost-effective and innovative way for the industry to use lasers.”

REFERENCE

1. S. Assa, Industrial Laser Solutions (September 2003).

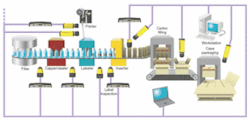

Vision systems keep laser codes in line

The packaging industry (including food, pharmaceuticals, and container inspection) represents the third largest market for machine-vision systems in the world, according to the market research firm Vision Systems International (Yardley, PA). One of the earliest applications of machine vision was inspection of returnable glass bottles before they were refilled, to ensure there were no visual contaminants in the bottom of the bottle and that the lip of the bottle was not damaged.

Today machine vision involves multiple high-speed cameras that track everything on a packaging production line from the bottle or package to the filling, sealing, placement, and position of each item. These cameras and sensors are also used to check the quality and placement of product labels and codes. In addition to reading barcode and mark registration, machine-vision systems can sense when a change has taken place in a print pattern, verify date and lot codes, and perform many other types of code and image “proofreading.”

“In the case of character code and number-letter combos, it is almost impossible to do anything other than presence/absence detection without machine vision,” said Mark Sippell, principal product marketing manager for Cognex (Natick, MA), whose In-Sight vision sensors, in conjunction with the new LabelInspect application, are used for optical character recognition (OCR) and optical character verification (OCV) in food and beverage packaging (see figure). Skewed character-string distortion is common on a production line because of improper synchronization of marking heads or line rates or when trying to mark on curved surfaces. The cameras can be programmed to read the font being used and the printer, as well as to recognize how the character can change from these distortions.“Printing on containers is not an exact science. You have different variables that can cause slight variation in the printing of the text. So without something that has dynamic read capability like a vision product, it is very difficult to adapt to that.”